Mitsubishi Lancer Evolution X. Manual - part 73

VALVE STEM SEAL

TSB Revision

ENGINE MECHANICAL

11A-45

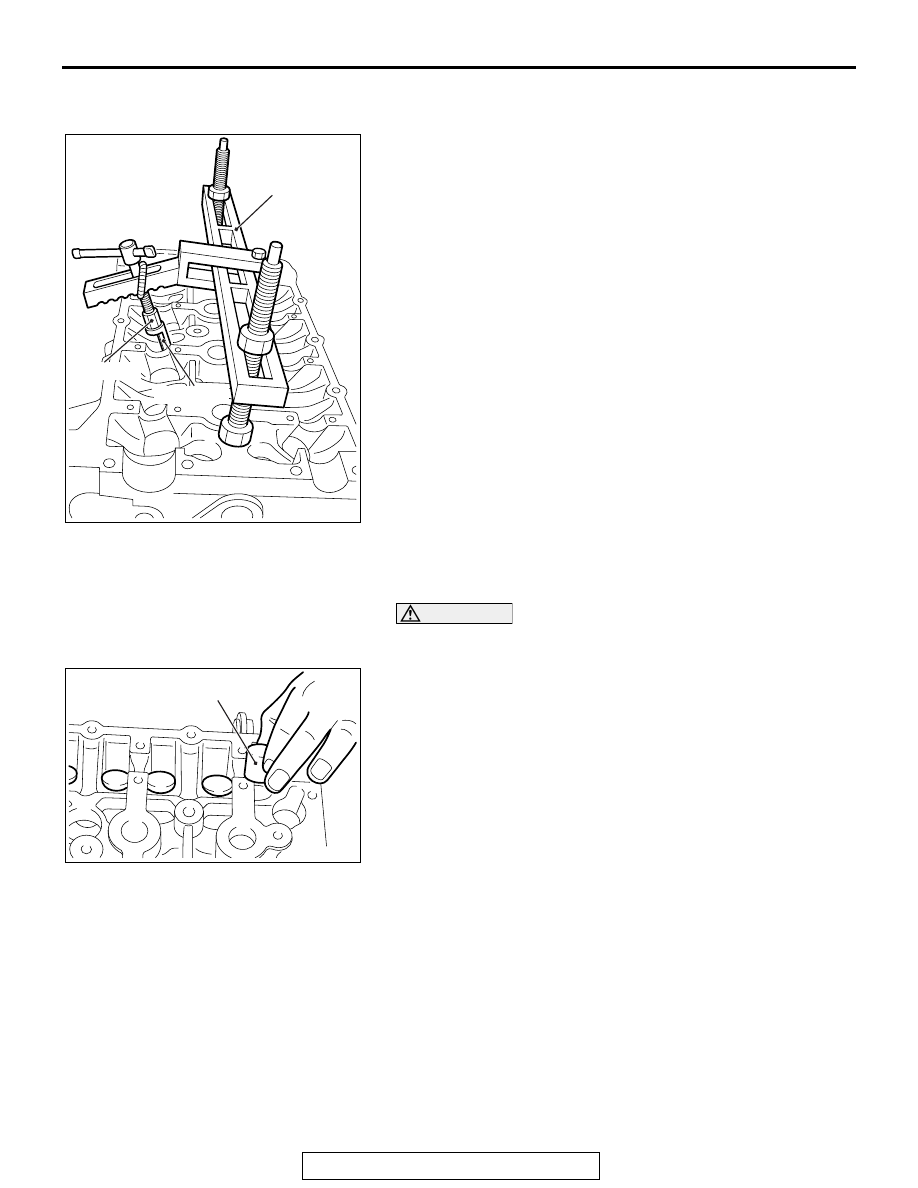

>>C<< VALVE SPRING RETAINER LOCK

INSTALLATION

In the same manner as removal, use special tool MD998772

with special tool MB992090 and special tool MB992089

attached to compress the valve spring, and install the valve

spring retainer lock.

.

>>D<< VALVE TAPPET INSTALLATION

1. Apply a small amount of engine oil to the valve tappets.

CAUTION

Be sure to install the valve tappets in the same position as

before.

2. Install the valve tappet to the cylinder head.

.

AC509271

AC

MD998772

MB992090

MB992089

AC509270

AC

Valve tappet