Mitsubishi Lancer Evolution X. Manual - part 67

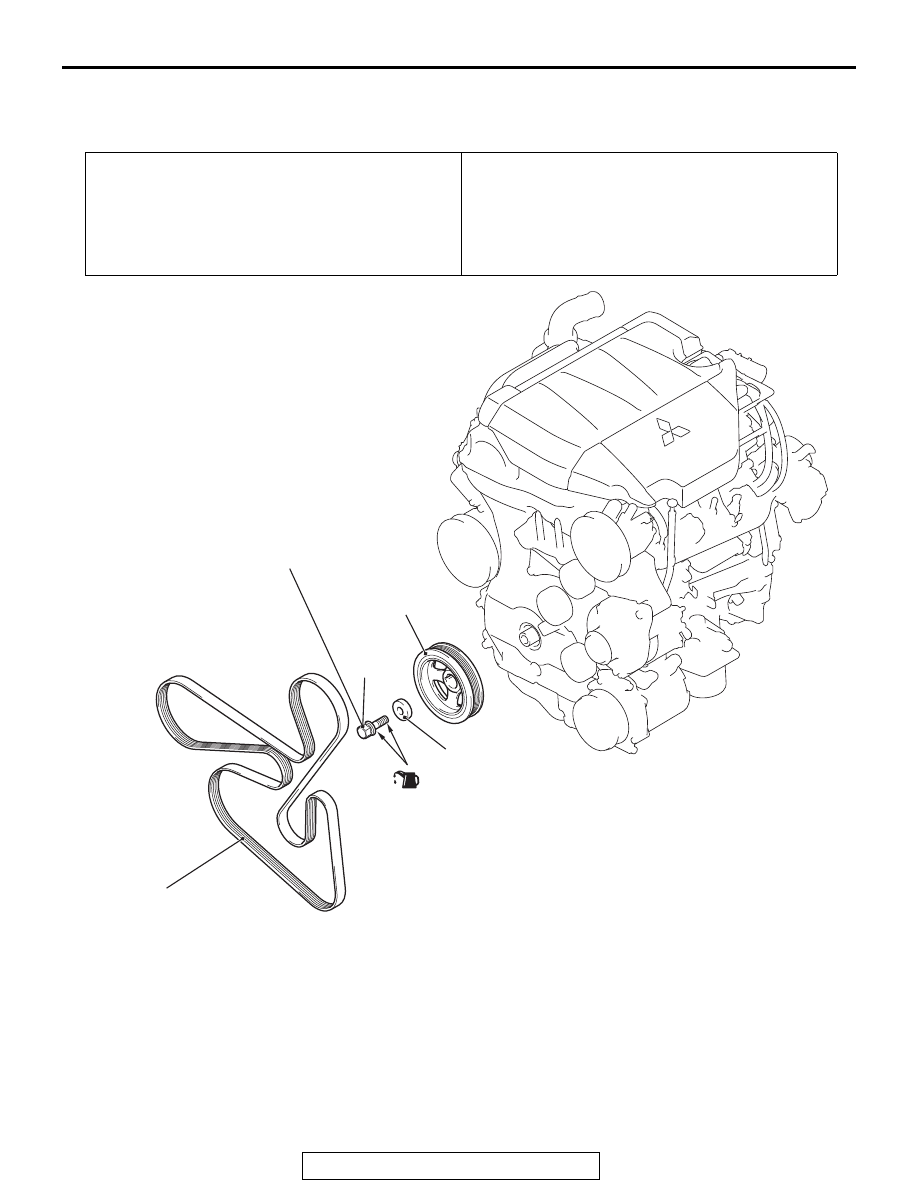

CRANKSHAFT PULLEY

TSB Revision

ENGINE MECHANICAL

11A-21

CRANKSHAFT PULLEY

REMOVAL AND INSTALLATION

M1112001603226

Pre-removal operation

• Engine Room Under Cover Front A, B, Engine Room

Under Cover Center and Engine Room Side Cover (RH)

Removal (Refer to GROUP 51, Under Cover

• Radiator Condenser Tank Bracket Removal (Refer to

GROUP 14, Radiator

).

Post-installation operation

• Drive Belt Tension Check (Refer to

• Radiator Condenser Tank Bracket Installation (Refer to

).

• Engine Room Under Cover Front A, B, Engine Room

Under Cover Center and Engine Room Side Cover (RH)

Installation (Refer to GROUP 51, Under Cover

AC704354AC

1

2

3

4

to 0 N·m to

250 N·m

184 ft-lb

to +60˚

110 N·m

81 ft-lb

(Engine oil)

Removal steps

<<

A

>>

>>

B

<<

1.

Drive belt

<<

B

>>

>>

A

<<

2.

Crankshaft pulley center bolt

<<

B

>>

>>

A

<<

3.

Crankshaft pulley washer

•

Engine mounting bracket (Refer

to GROUP 32, Engine Mounting

)

>>

A

4.

Crankshaft pulley

Removal steps (Continued)