Mitsubishi Lancer Evolution VI. Manual - part 107

CHASSIS ELECTRICAL –

Headlamp

54-32

HEADLAMP

SERVICE SPECIFICATIONS

Items

Standard value

Limit

Headlamp

aiming

High

beam

Vertical direction

25’ (22 mm) below horizontal line

–

aiming

[Parenthe-

sized are

allowable

beam

Horizontal

direction

Left head-

lamp

Parallel to direction of vehicle travel

–

allowable

beam axis

deviations 3

m ahead of

Right head-

lamp

15’ (13 mm) leftward from vertical line (V)

–

m ahead of

headlamp.]

Low

beam

Vertical direction

25’ (22 mm) below horizontal line

–

p ]

beam

Horizontal direction

Position where 15* rising section intersects

vertical line (V)

–

Headlamp intensity cd (Center of high-beam high intensity

zone)

–

15,000 or

more per

light

Cautions in Handling Headlamp Assembly

Each headlamp assembly has a plastic outer lens on. Observe the do’s and don’ts below when

handling the headlamps.

D

Do not leave the headlamps lit for longer than 3 minutes with a protective cover on.

D

Do not mask the outer lens surface by taping or in any other way.

D

Do not scrub the outer lens surface with a pointed tool.

D

Use the designated wax remover for cleaning the outer lens surface. Rinse it thoroughly.

D

Use the designated genuine bulbs.

SPECIAL TOOLS

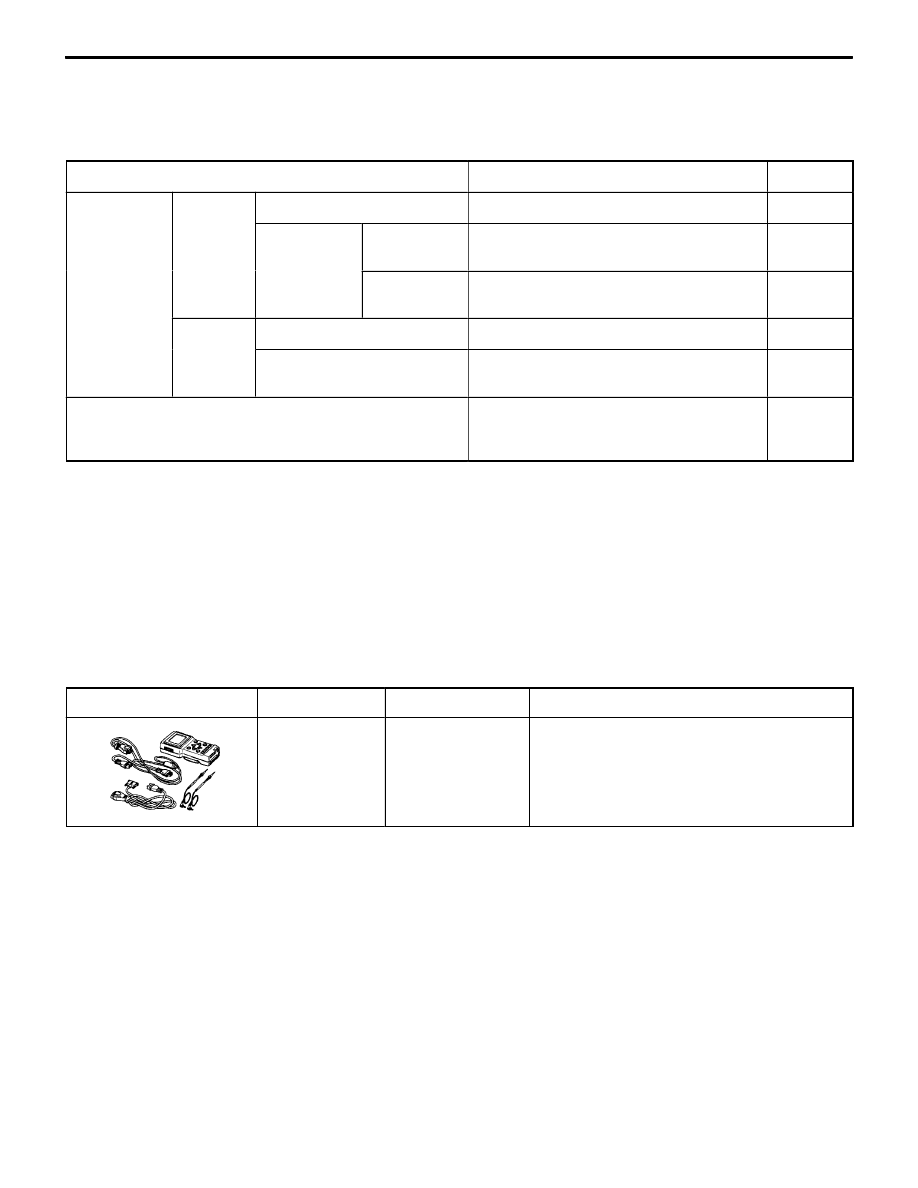

Tool

Number

Name

Use

MB991502

MUT-

II

sub as-

sembly

ETACS-ECU input signal checking