Mitsubishi Lancer Evolution VI. Manual - part 11

ENGINE –

Timing Belt

11-19

"

D

A

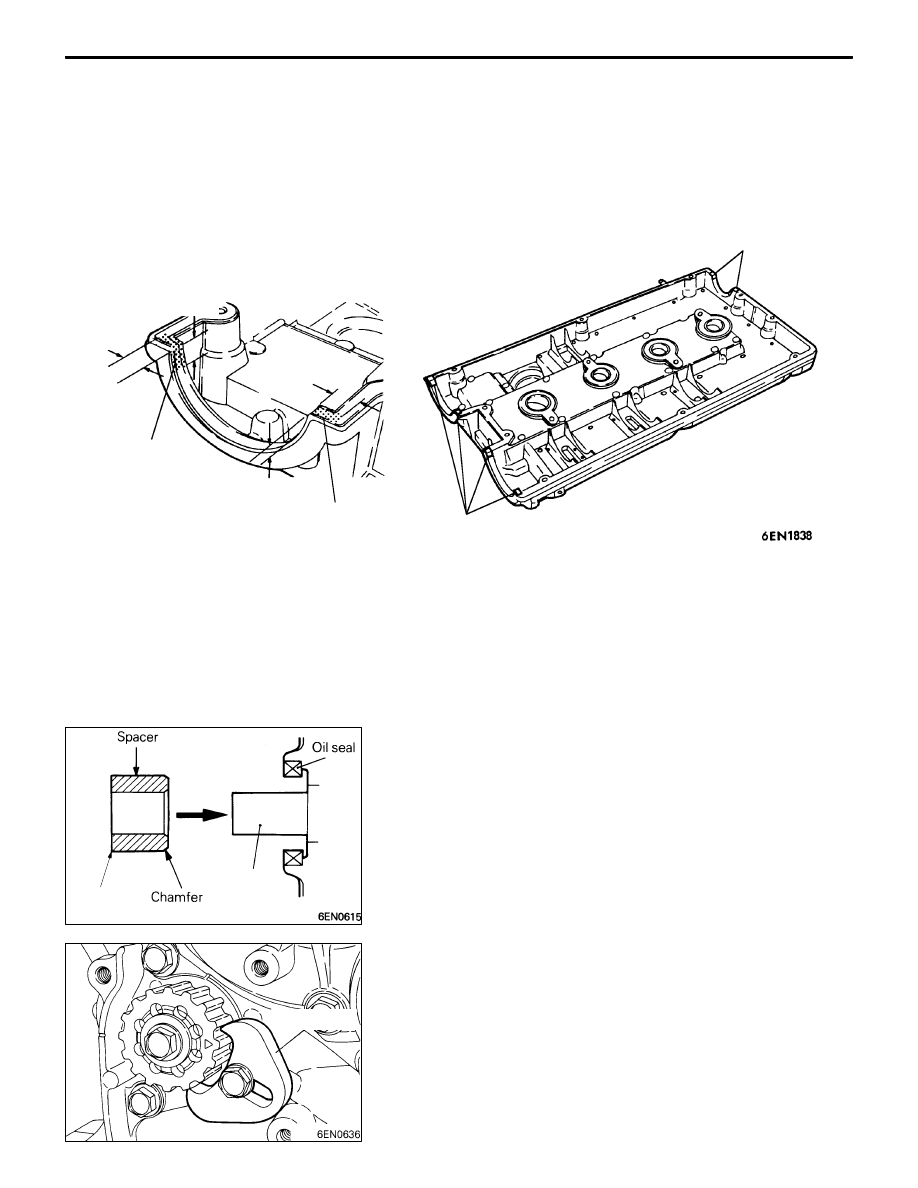

SEALANT APPLICATION TO ROCKER COVER

Apply sealant to the areas indicated in the illustration.

Specified sealant: 3M

TM

AAD Part No. 8672 or equivalent

Apply sealant

Apply sealant

Apply sealant

10 mm

10 mm

10 mm

10 mm

Apply sealant

"

E

A

SPACER INSTALLATION

Install the spacer with the chamfered end toward the oil seal.

"

F

A

COUNTERBALANCE SHAFT SPROCKET

INSTALLATION

(1) Install the counterbalance shaft sprocket and screw the

bolt.

(2) Install special tool MD998785 as shown in the illustration

to lock the counterbalance shaft.

(3) Tighten the bolt, and then remove the special tool.

Counter-

balance

shaft

Sharp

edge

MD998785