Mitsubishi Eclipse / Eclipse Spyder (2000-2002). Service and repair manual - part 588

ANTI-SKID BRAKING SYSTEM (ABS) DIAGNOSIS

TSB Revision

ANTI-LOCK BRAKING SYSTEM (ABS)

35B-43

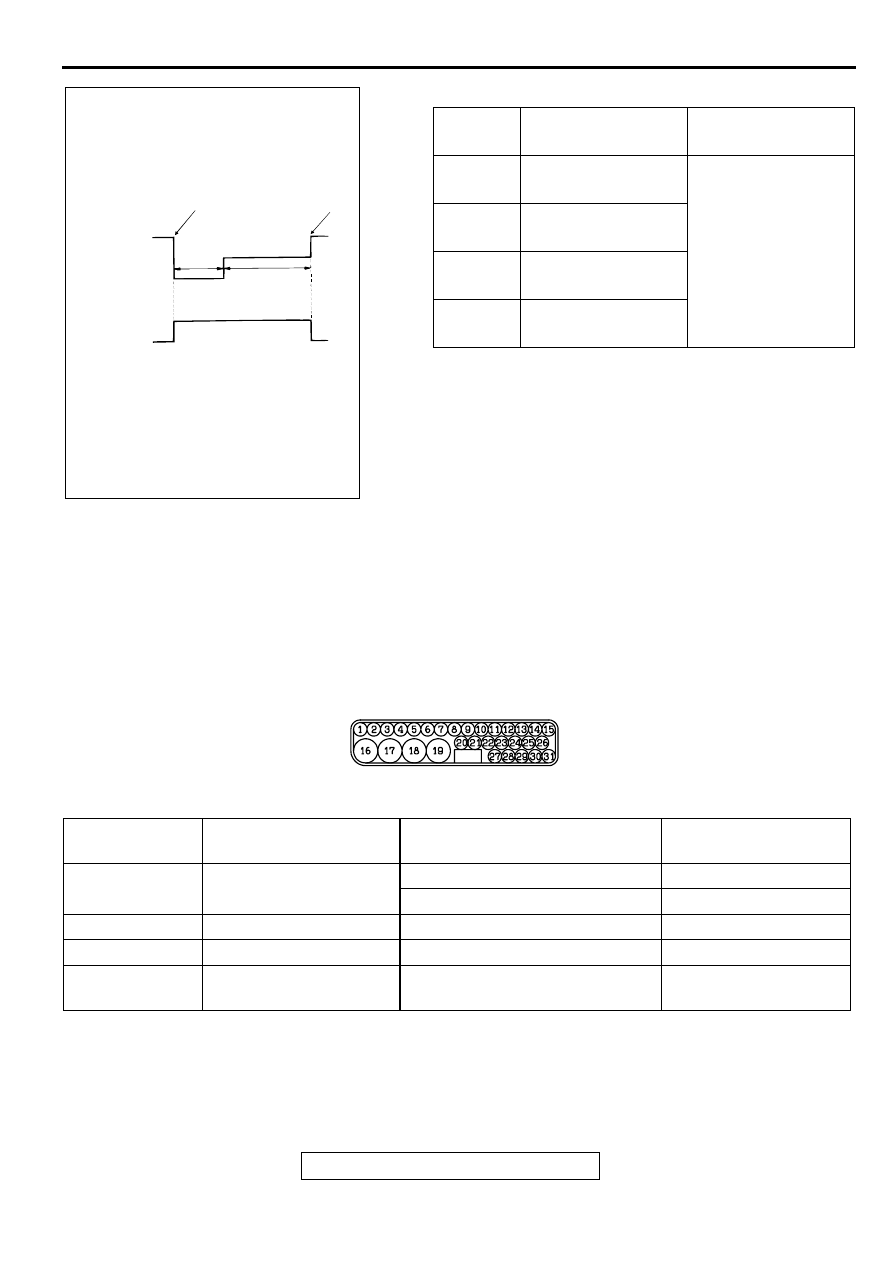

ACTUATOR TEST SPECIFICATIONS

CHECK AT ABS-ECU

M1352011800093

TERMINAL VOLTAGE CHECK CHART

1. Measure the voltages between terminals (16) and

(19) (ground terminals) and each respective

terminal.

2. The terminal layouts are shown in the illustrations

below.

NOTE: Do not measure terminal voltage for

approximately three seconds after the ignition switch

is turned "ON." The ABS-ECU performs the initial

check during that period.

RESISTANCE AND CONTINUITY BETWEEN

HARNESS-SIDE CONNECTOR TERMINALS

1. Turn the ignition switch to the "LOCK" (OFF)

position and disconnect the ABS-ECU connectors

before checking resistance and continuity.

2. Check between the terminals indicated in the

table below.

3. The terminal layouts are shown in the illustration

below.

NO.

ITEM

PARTS TO BE

ACTIVATED

01

Solenoid valve for

front-left wheel

Solenoid valves and

pump motors in the

hydraulic unit (simple

inspection mode)

02

Solenoid valve for

front-right wheel

03

Solenoid valve for

rear-left wheel

04

Solenoid valve for

rear-right wheel

AC000971AC

ACTIVATION PATTERN

A

B

C

SOLENOID

VALVE

END OF

FORCED

ACTION

START OF

FORCED

ACTION

1 s

2 s

PUMP

MOTOR

ON

OFF

NOTE

A:

B:

C:

HYDRAULIC PRESSURE DECREASES

HYDRAULIC PRESSURE HOLDS

HYDRAULIC PRESSURE INCREASES

AC002089 AB

CONNECTOR

TERMINAL NO

SIGNAL

CHECKING REQUIREMENT

NORMAL CONDITION

14

Input from stoplight

switch

Stoplight switch: ON

Battery positive voltage

Stoplight switch: OFF

Approximately 0 V

15

ABS-ECU power supply

Ignition switch: "ON"

Battery positive voltage

17

Motor power supply

Always

Battery positive voltage

18

Solenoid valve power

supply

Always

Battery positive voltage