Mitsubishi Eclipse. Manual - part 752

AUTOMATIC TRANSAXLE DIAGNOSIS

TSB Revision

AUTOMATIC TRANSAXLE

23A-17

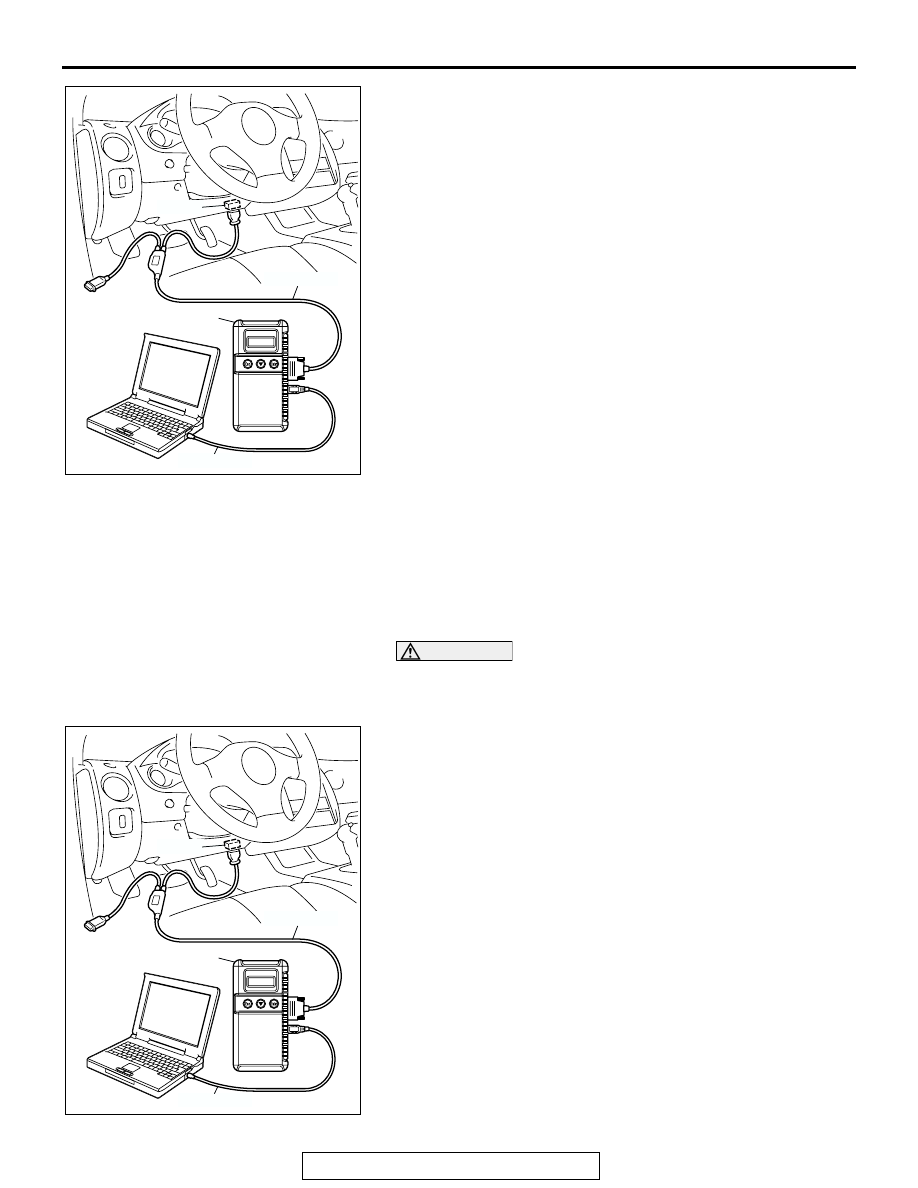

1. Connect scan tool MB991958 to the data link connector.

2. Turn the ignition switch to the "ON" position.

3. Select "Interactive Diagnosis" from the start-up screen.

4. Select "System select."

5. Choose "ELC-A/T" from the "POWER TRAIN" tab.

6. Select "MITSUBISHI."

7. Select "Diagnostic Trouble Code."

8. If a DTC is set, it is shown.

9. Choose "Erase DTCs" to erase the DTC.

HOW TO READ DATA LIST

Required Special Tools:

• MB991958: Scan Tool (MUT-III Sub Assembly)

• MB991824: V.C.I.

• MB991827: MUT-III USB Cable

• MB991911: MUT-III Main Harness B

CAUTION

To prevent damage to scan tool MB991958, always turn the

ignition switch to the "LOCK" (OFF) position before con-

necting or disconnecting scan tool MB991958.

1. Connect scan tool MB991958 to the data link connector.

2. Turn the ignition switch to the "ON" position.

3. Select "Interactive Diagnosis" from the start-up screen.

4. Select "System select."

5. Choose "ELC-A/T" from the "POWER TRAIN" tab.

6. Select "MITSUBISHI."

7. Select "Data List."

8. Choose an appropriate item and select the "OK" button.

AC303127

AB

MB991911

16-PIN

MB991827

MB991824

AC303127

AB

MB991911

16-PIN

MB991827

MB991824