Mitsubishi Colt Ralliart. Manual - part 539

COMPRESSOR ASSEMBLY

HEATER, AIR CONDITIONER AND VENTILATION

55A-64

REMOVAL SERVICE POINTS

<<A>> FLEXIBLE SUCTION HOSE AND

FLEXIBLE DISCHARGE HOSE DISCON-

NECTION

CAUTION

Use the plug which is not breathable because

A/C compressor oil or receiver have high hygro-

scopicity.

Plug the removed nipple of the pipe, hose and

expansion valve to prevent the entry of dust and dirt.

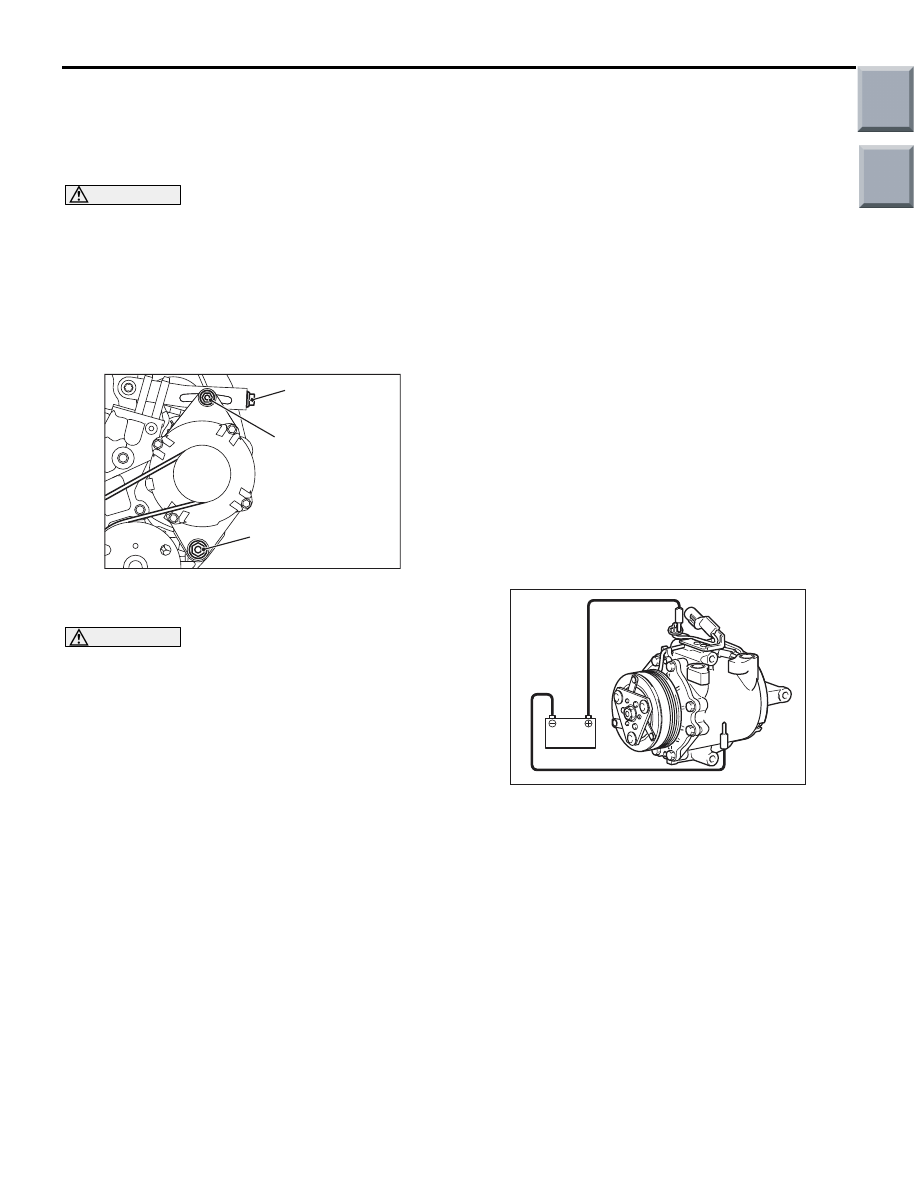

<<B>> A/C COMPRESSOR DRIVE BELT

REMOVAL

AC310987AB

Nut for alternator

pivot bolt

Adjusting bolt

Alternator fixing nut

1. Loosen the nut for alternator pivot bolt and

alternator fixing nut.

CAUTION

To reuse the drive belt, draw an arrow indicating

the rotating direction (clockwise) on the back of

the belt using chalk, etc.

2. Turn the adjusting bolt in the anti-clockwise

direction (to the left) to remove the drive belt.

<<C>> A/C COMPRESSOR REMOVAL

Be careful not to spill the A/C compressor oil and

remove the A/C compressor.

INSTALLATION SERVICE POINT

>>A<< A/C COMPRESSOR INSTALLA-

TION

When installing the new A/C compressor, install the

A/C compressor after adjusting the oil volume as fol-

lows.

1. Measure the oil of A/C compressor removed.(X

cm

3

)

2. Drain the oil (Y cm

3

) given by the following

expression from a new A/C compressor, and then

install the A/C compressor.

140 cm

3

- X cm

3

= Y cm

3

NOTE:

.

•

140 cm

3

shows the oil volume contained in the

new A/C compressor.

•

Y cm

3

shows the oil volume stored in the

refrigerant line, condenser, and cooling unit,

etc.

INSPECTION

M1552004500243

COMPRESSOR MAGNETIC CLUTCH

OPERATION CHECK

AC208432

Connect the connector battery to positive battery ter-

minal in the A/C compressor, and then earth the bat-

tery (

−) terminal to the A/C compressor itself. At this

time, check that the magnetic clutch operating sound

can be heard.

Main

Index

Group

TOC