Mitsubishi Colt Ralliart. Manual - part 312

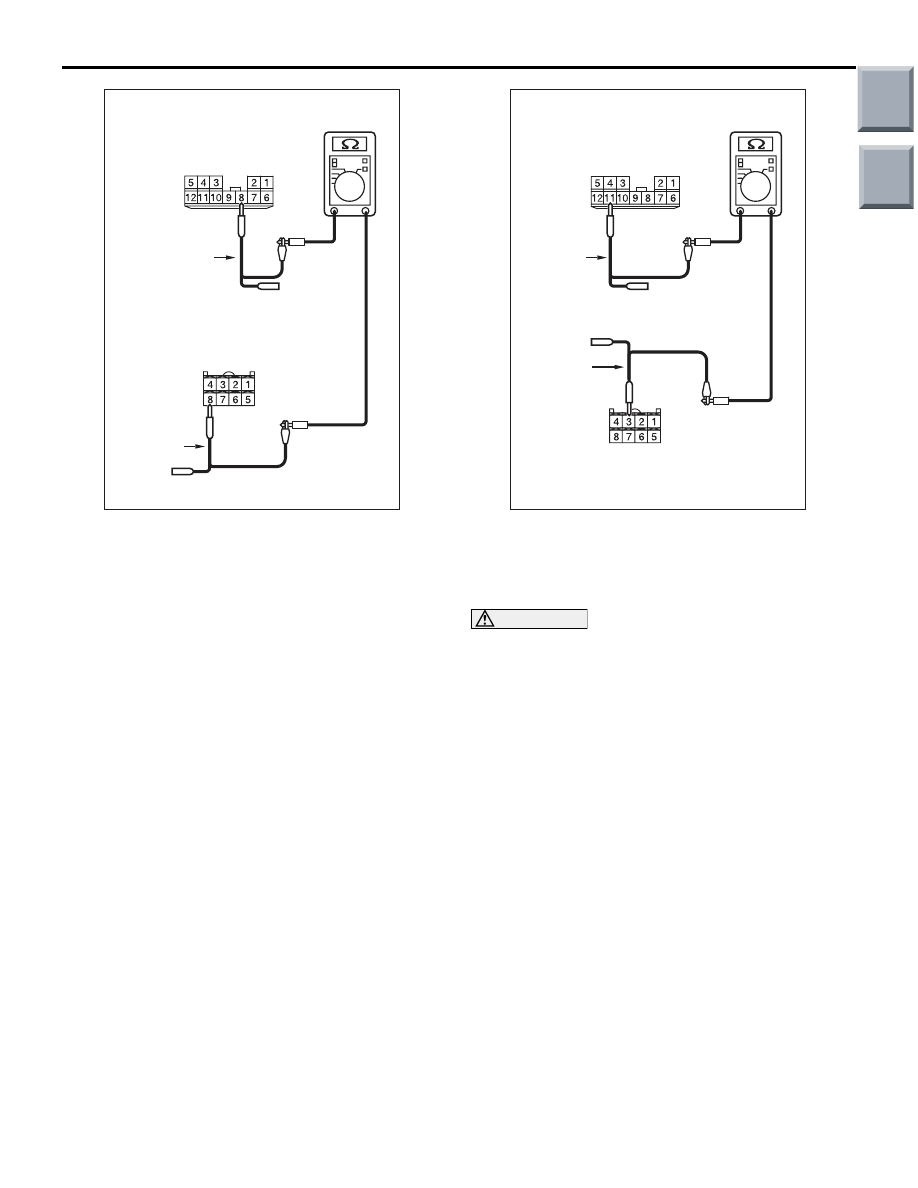

AC313937AT

Harness side: B-01

Harness side: B-37

Test

harness

Test

harness

TROUBLESHOOTING

CONTROLLER AREA NETWORK (CAN)

54D-77

(4) Continuity between B-01 joint connector (CAN2)

terminal No.8 and B-37 EPS-ECU connector

terminal No.8

OK: Continuity (2

Ω or less)

AC313937AU

Harness side: B-01

Harness side: B-37

Test

harness

Test

harness

(5) Continuity between B-01 joint connector (CAN2)

terminal No.11 and B-37 EPS-ECU connector

terminal No.3

OK: Continuity (2

Ω or less)

CAUTION

Strictly observe the specified wiring harness

repair procedure. For details refer to

Q: Is the check result normal?

YES :

<All the resistances measure 2

Ω or less>

Power supply to the EPS-ECU may be

suspected. Diagnose the EPS. Refer to

GROUP 37

− Troubleshooting

.

NO :

<Either or all of the resistances measure

more than 2

Ω> Repair the wiring harness

between the joint connector (CAN2) and the

EPS-ECU connector.

Main

Index

Group

TOC