Mitsubishi Colt Ralliart. Manual - part 266

TIMING CHAIN

ENGINE OVERHAUL <4A9>

11B-28

NOTE: Valve tappets are available in 31 sizes, at

0.02 mm intervals in the 2.70

−

3.30 mm range.

AK304938

AB

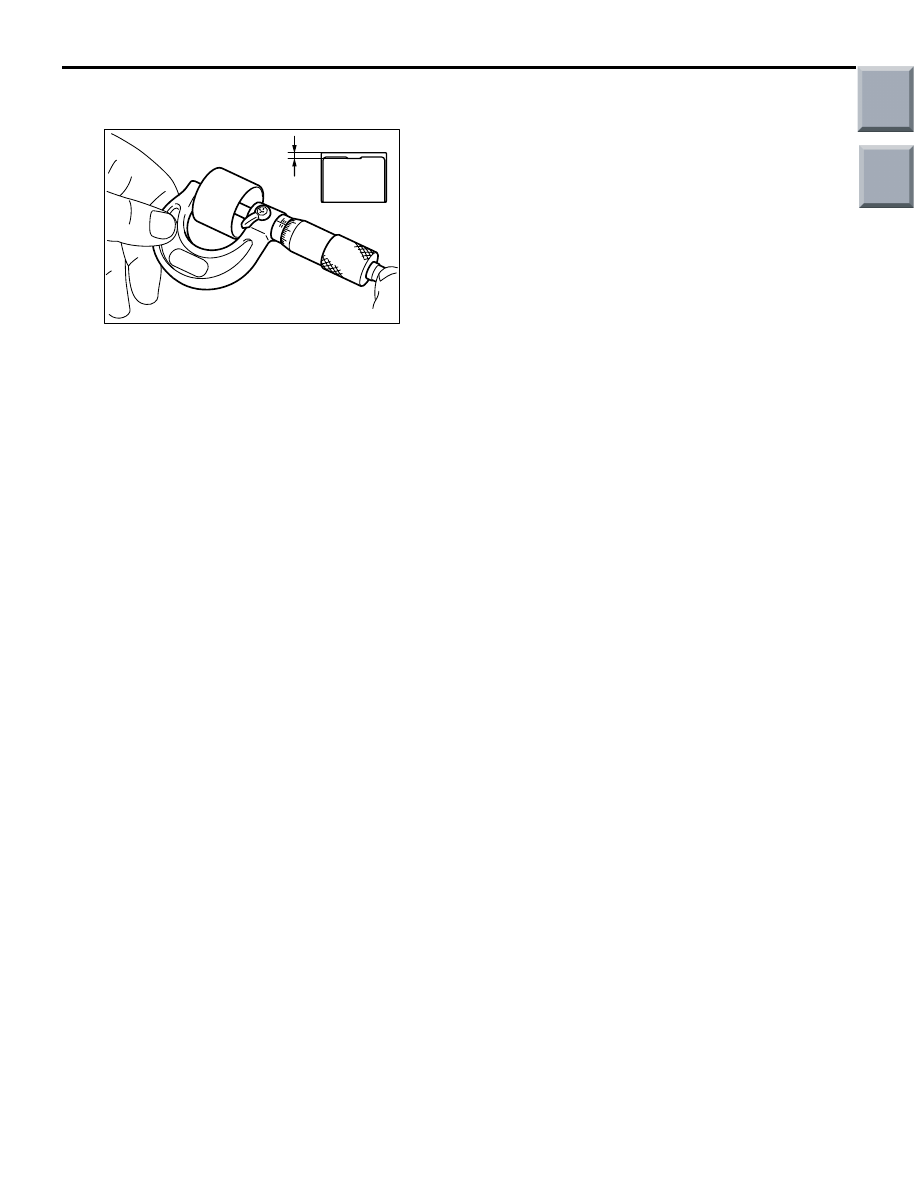

Wall

thickness

9. Valve tappets should be selected in the following

manner.

(1) Remove the valve tappet and measure its

thickness.

(2) Calculate the correct thickness for a new valve

tappet as follows that achieves the standard

valve clearance.

A: Thickness of new valve tappet

B: Thickness of old valve tappet

C: Measured valve clearance

Equation:

Intake valve A = B + (C

− 0.22 mm)

Exhaust valve A = B + (C

− 0.30 mm)

For removal and installation procedures for the valve

tappet, refer to "CAMSHAFT REMOVAL AND

INSTALLATION."

(Refer to Camshaft Removal and Installa-

tion.

Main

Index

Group

TOC