Mitsubishi Colt Ralliart. Manual - part 246

ON-VEHICLE SERVICE

ANTI-SKID BRAKING SYSTEM (ABS)

35B-76

ON-VEHICLE SERVICE

HYDRAULIC UNIT CHECK

M1352001700705

1. Raise the vehicle, and support the specified area

on axle stands.

CAUTION

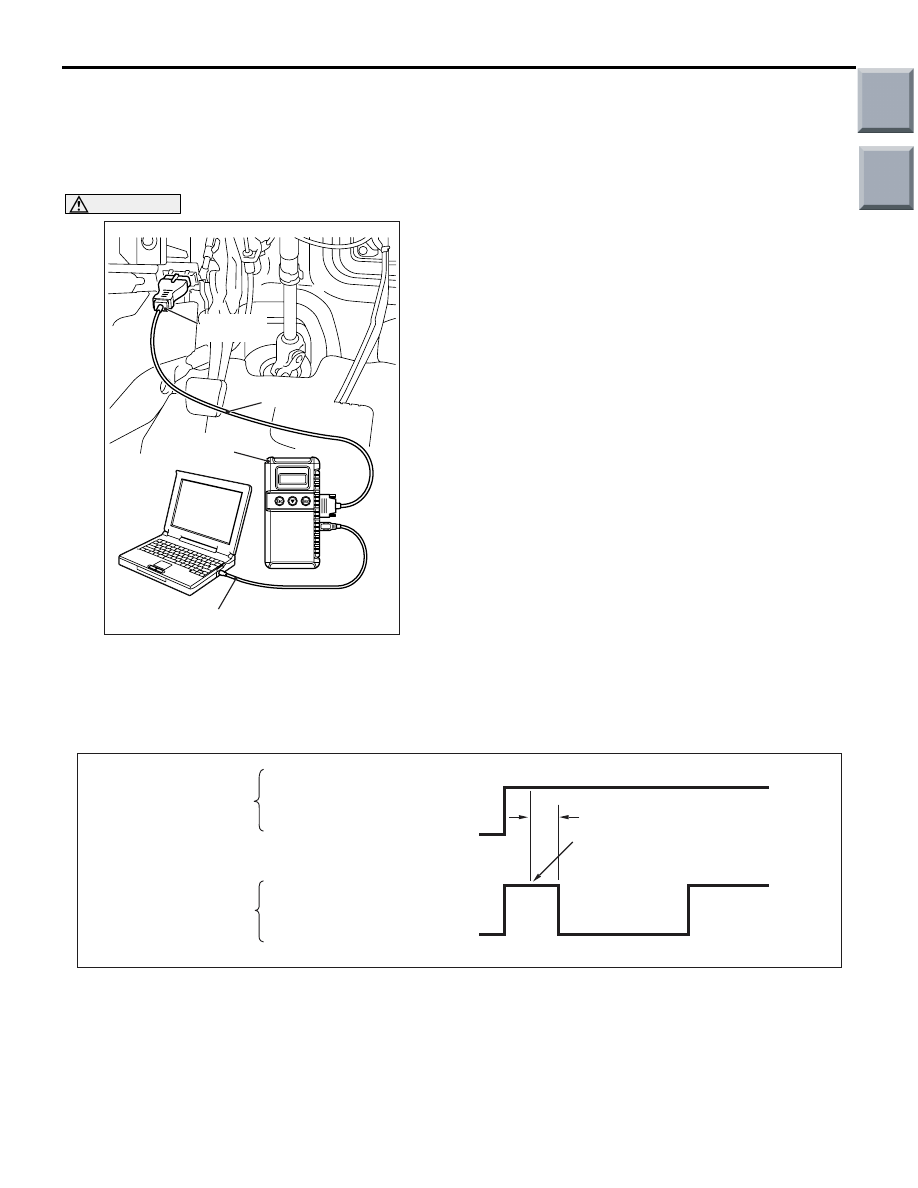

Before connecting or disconnecting the

M.U.T.-III, turn the ignition switch to the "LOCK"

(OFF) position.

2. Turn the ignition switch to the "LOCK (OFF)"

position, and then set the M.U.T.-III.

3. Check that the selector lever is "N" position, and

then start the vehicle engine.

4. Operate the M.U.T.-III to execute the actuator test

while depressing the brake pedal. When

executing the actuator test, check that the braking

force changes by rotating the wheel with your

hand.

NOTE: During the actuator test, the ABS warning

lamp illuminates and ABS control is prohibited.

NOTE: When the ABS-ECU is not working due to

the fail-safe, the M.U.T.-III actuator test cannot be

executed.

5. This is indicated as shown above.

6. When it is abnormal as a result of the inspection,

take action as described on the "Judgment table".

AC206895

AD

Diagnosis

connector

MB991827

MB991824

MB991910

AC106011

M.U.T.-III actuator test

(No.01, 02, 03, 04) start

Approx. 3 seconds

Pedal operation

Drag force when pedal is free

Lock

Depress

Release

Brake force check

AD

Approx. 0.05 seconds

Main

Index

Group

TOC