Mitsubishi Colt Ralliart. Manual - part 208

STRUT ASSEMBLY

FRONT SUSPENSION

33-9

DISASSEMBLY SERVICE POINTS

<<A>> STRUT NUT (SELF-LOCKING NUT)

REMOVAL

CAUTION

• Install special tool arm set (MB991238) evenly,

and so that the maximum length will be

attained within the installation range.

•

AC001085AB

MB991238

MB991237

Do not use an impact wrench to tighten the

bolt of special tool spring compressor body

(MB991237), otherwise the special tool will

break.

1. Use following special tools to compress the coil

spring.

• Spring compressor body (MB991237)

• Arm set (MB991238)

WARNING

Do not use an impact wrench to remove the

strut nut (self-locking nut). Vibration of the

impact wrench will cause special tools

(MB991237 and MB991238) to slip and cause

personal injury.

AC006091 AB

MB991681

MB991682

2. Use following special tools to secure the strut, and

then remove the strut nut (self-locking nut).

• Wrench (MB991681)

• Socket (MB991682)

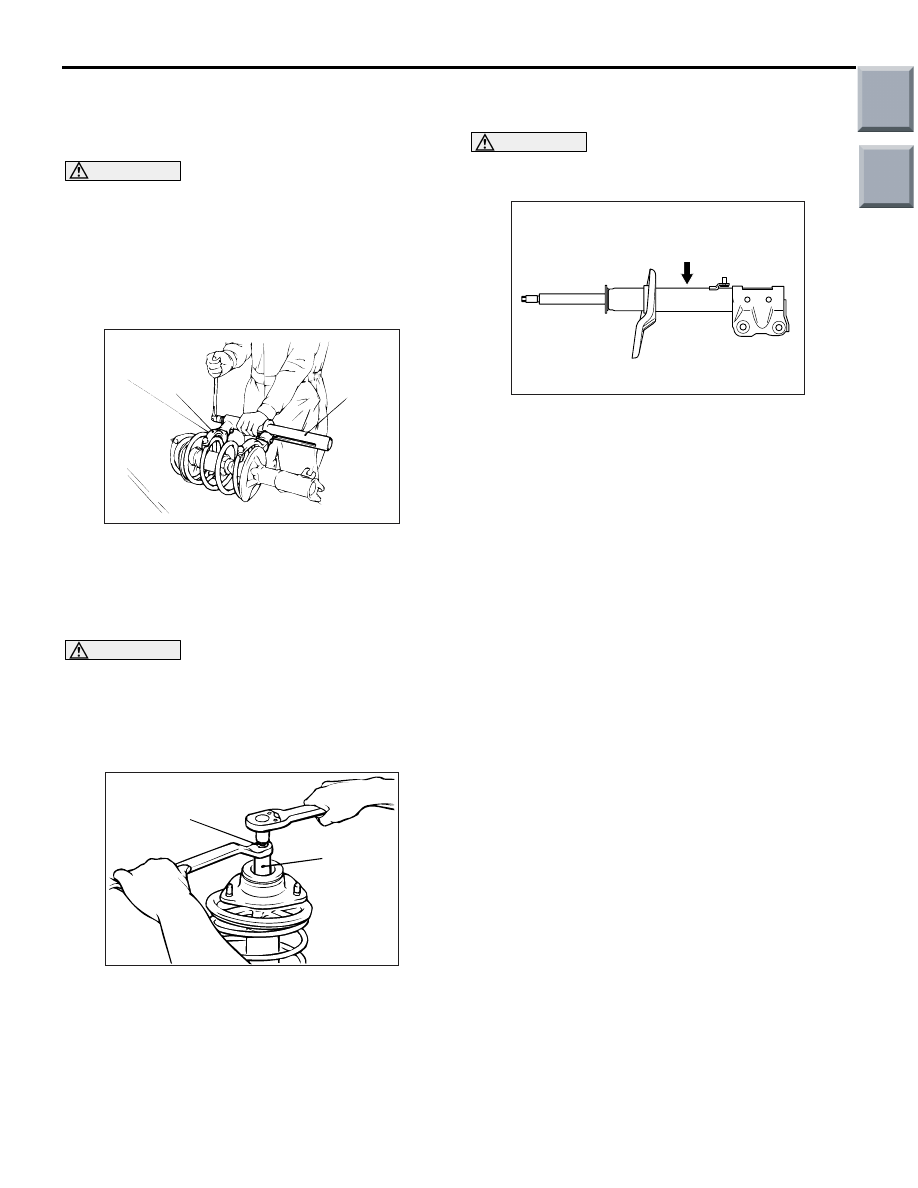

<<B>> STRUT DISPOSAL

WARNING

Wear goggles when drilling to protect your

eyes from flying metal debris.

AC207801

AC

The gas must be discharged from the strut before

discarding it. Place the strut horizontally with its pis-

ton rod extended. Then drill a hole of approximately

3 mm in diameter at the location shown in the illustra-

tion and discharge the gas.

Main

Index

Group

TOC