Mitsubishi Colt Ralliart. Manual - part 207

MB990800

ON-VEHICLE SERVICE

FRONT SUSPENSION

33-5

ON-VEHICLE SERVICE

FRONT WHEEL ALIGNMENT CHECK AND

ADJUSTMENT

M1331000901050

Measure wheel alignment with alignment equipment

on a level surface. The front suspension, steering

system, wheels, and tyres should be serviced to nor-

mal condition before measuring wheel alignment.

TOE-IN

Standard value:

At the centre of tyre tread: 0

± 2 mm

Toe angle (per wheel): 0

°00' ± 0°06'

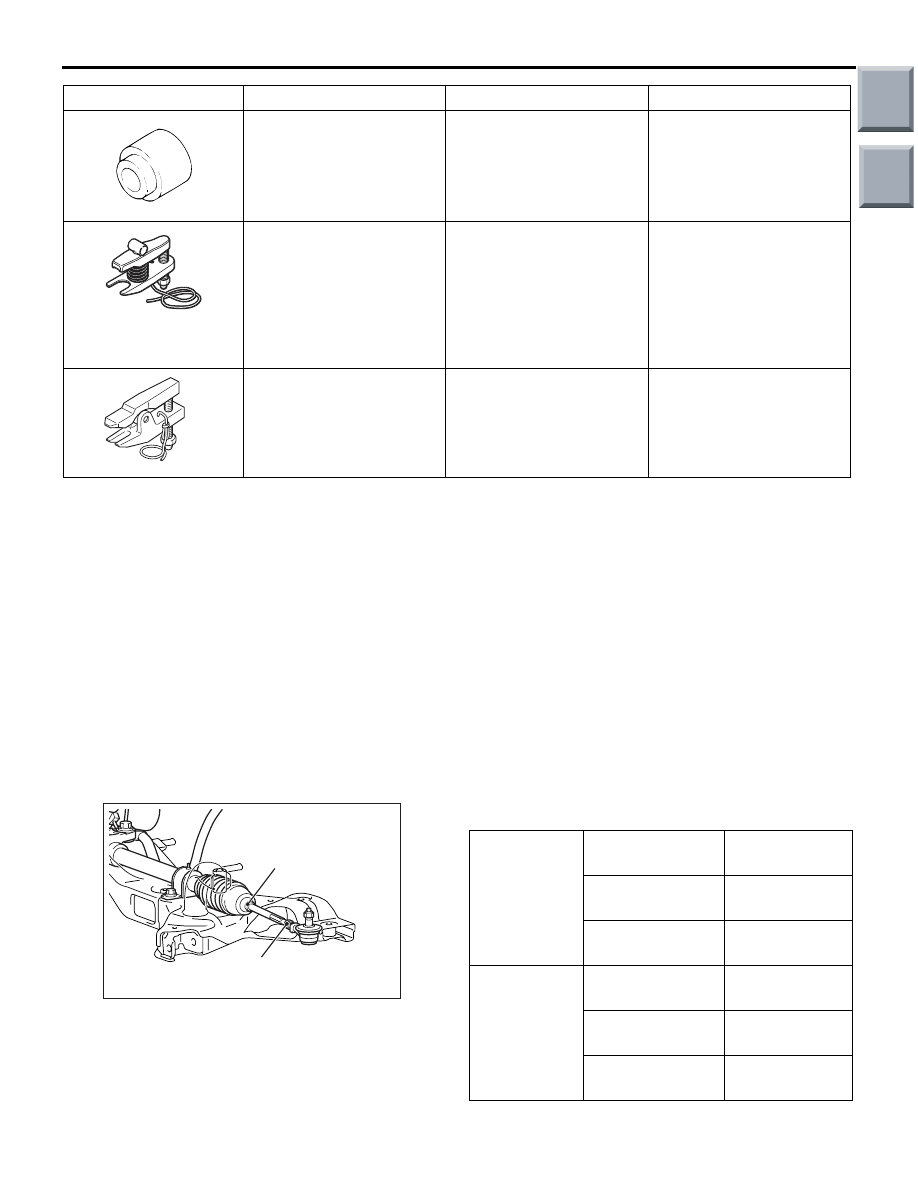

AC209087AE

Lock nut

Clip

1. Adjust the toe-in by undoing the clip and lock nut,

and turning the left and right tie rod turnbuckles by

the same amount (in opposite directions).

NOTE: The toe will move out as the left turnbuckle

is turned toward the front of the vehicle and the

right turnbuckle is turned toward the rear of the

vehicle.

2. Install the clip and tighten the lock nut to the

specified torque.

Tightening torque: 43

± 7 N⋅m

3. Confirm that the toe-in is at the standard value.

4. Use a turning radius gauge to check that the

steering angle is at the standard value.

STEERING ANGLE

Standard value:

Inner wheels

Vehicles with

14-inch wheels

41

° 40' ± 1° 30'

Vehicles with

15-inch wheels

39

° 00' ± 1° 30'

Vehicles with

16-inch wheels

34

° 10' ± 1° 30'

Outer wheels

(reference)

Vehicles with

14-inch wheels

35

° 30'

Vehicles with

15-inch wheels

33

° 40'

Vehicles with

16-inch wheels

30

° 00'

MB990800

Ball joint remover and

installer

Lower arm ball joint cover

installation

MB991897

MB991897 or MB992011

Ball joint remover

Knuckle and ball joint

disconnection <4A9>

NOTE: Steering linkage

puller (MB990635 or

MB991113)is also used to

disconnect knuckle and tie

rod end ball joint.

B991113

MB991113

Steering linkage puller

Knuckle and ball joint

disconnection <4G1>

Tool

Number

Name

Use

Main

Index

Group

TOC