Mitsubishi Colt Ralliart. Manual - part 201

TRANSMISSION CONTROL

CVT

23A-147

REMOVAL SERVICE POINTS

<<A>> KEY INTERLOCK ROD REMOVAL

CAUTION

Do not bend the key interlock rod cable.

Turn the ignition switch to the ACC position and then

pull the key interlock rod out from the ignition key cyl-

inder.

INSTALLATION SERVICE POINTS

>>A<< TRANSMISSION CONTROL

CABLE (TRANSMISSION SIDE) INSTAL-

LATION

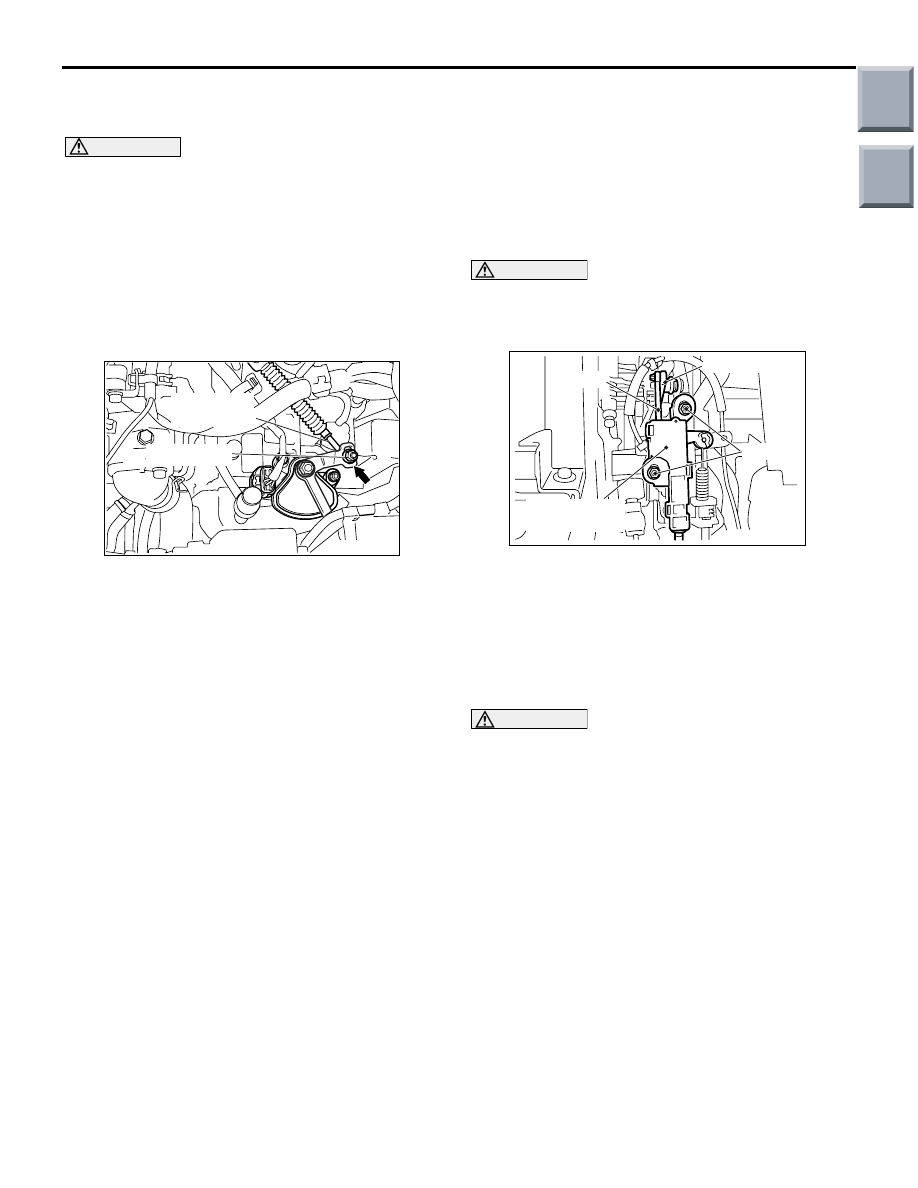

AC103395AD

Adjusting nut

Transmission

control cable

1. Shift the selector lever and manual control lever to

the N position.

2. Gently push the transmission control cable in the

direction of the arrow (with a force of

approximately 5 N) to tighten the adjusting nut to

the specified torque.

Tightening torque: 12

± 2 N⋅m

>>B<< TRANSMISSION CONTROL

CABLE (SELECTOR LEVER SIDE)

INSTALLATION

Ensure that the transmission control cable is con-

nected securely.

>>C<< SHIFT LOCK CALBLE UNIT/SHIFT

LOCK ROD INSTALLATION

CAUTION

Do not bend the shift lock cable.

1. Shift the selector lever to the P position and turn

the ignition switch to the LOCK (OFF) position.

AC208298

AB

Bolt

Rod

Lock cam

Shift lock cable

unit

2. After installing the shift lock rod to the lock cam of

the selector lever assembly, tighten the bolts of

the shift lock cable unit to the specified torque.

Tightening torque: 5.0

± 1.0 N⋅m

>>D<< KEY INTERLOCK ROD

INSTALLATION

CAUTION

Do not bend the key interlock rod cable.

Turn the ignition switch to the ACC position and then

install the key interlock rod through the ignition key

cylinder.

Main

Index

Group

TOC