Mitsubishi Colt Ralliart. Manual - part 166

TROUBLESHOOTING <CVT>

CVT

23A-7

TROUBLESHOOTING <CVT>

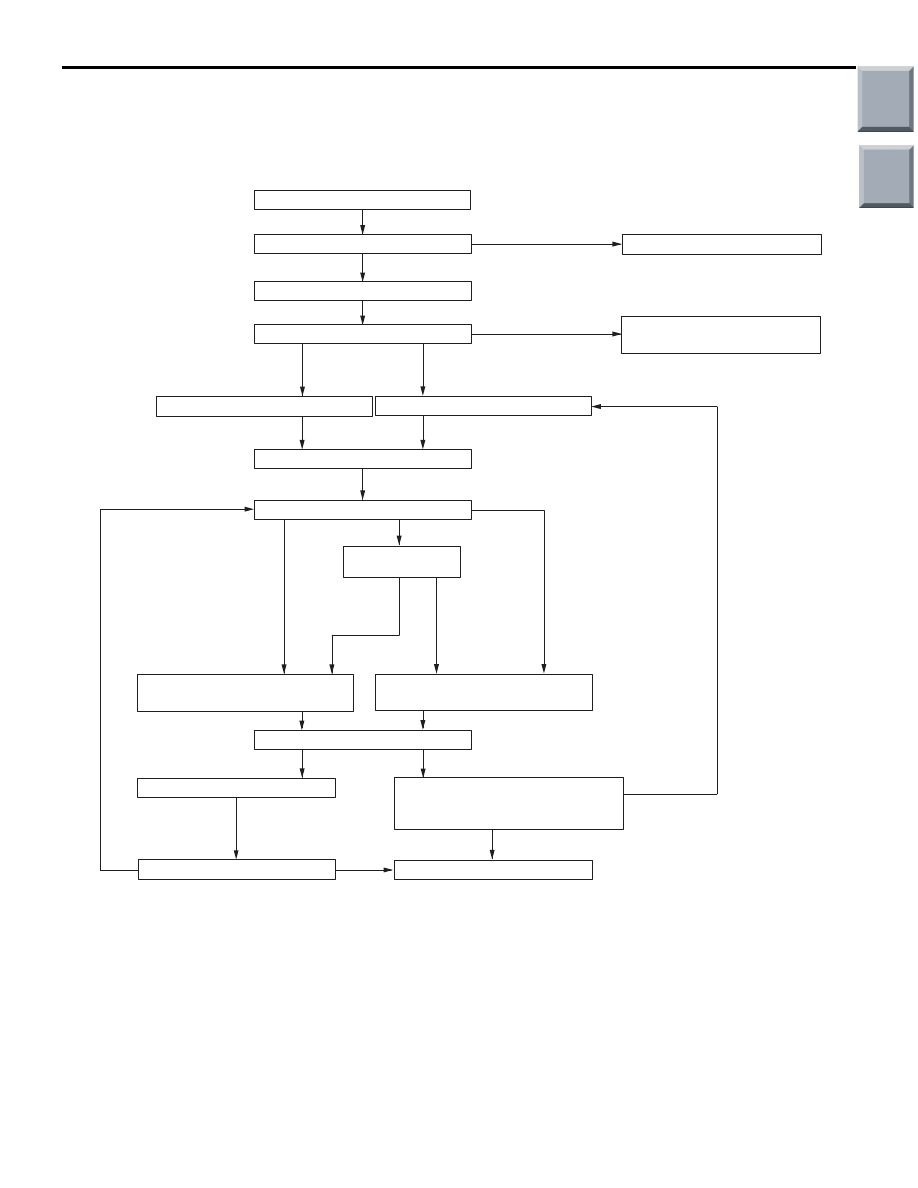

STANDARD FLOW OF DIAGNOSIS

TROUBLESHOOTING

M1231213500090

OK

OK

NG

AC314016

NG

NG

OK

Ask about trouble symptoms

Check the CVT fluid

Check the trouble symptoms

Replace the CVT fluid

To INSPECTION CHART FOR

TROUBLE SYMPTOMS

Reading of a diagnosis code

Erase of a diagnosis code

Check the trouble symptoms

Inhibitor switch, TPS check

Road test

Recheck diagnosis

codes

To INSPECTION CHART FOR

DIAGNOSIS CODES

To INSPECTION CHART FOR

TROUBLE SYMPTOMS

Check for the cause

Repair

Confirmation test (road test)

INTERMITTENT MALFUNCTIONS

(Refer to GROUP 00 - Points to

Note for Intermittent Malfunction)

Completed

Diagnosis code output

exists

No diagnosis code output

Abnormality exists

(no diagnosis code output)

Abnormality exists

(diagnostic trouble

code output)

No abnormality

Found

Not found

Diagnosis code

output exists

No diagnosis

code output

Communication with the

MUT-III not possible

Communication with the

M.U.T.-III not possible

LEARNED VALUE INITIALIZATION

PROCEDURE FOR CVT

M1231202400077

AIM

The use of EEPROM has enabled the CVT learned

value to be retained even after the battery terminals

are disconnected. However, the learned value should

be initialised if the CVT assembly, the engine assem-

bly, the valve body assembly or the solenoid valves

are replaced. The initialisation procedure is as

below:

INITIALISATOIN PROCEDURE

1. Shift the selector lever to the P range and turn the

ignition switch to the LOCK (OFF) position. Then,

connect the M.U.T.-III to the diagnosis connector.

2. Initialise the learned value on the initialisation

screen.

3. After this initialization, make the system learn the

hydraulic pressure control in accordance with

"CVT Fluid Pressure Control Learning

Procedure."(Refer to

Main

Index

Group

TOC