Mitsubishi Colt Ralliart. Manual - part 132

EMISSION CONTROL

ENGINE AND EMISSION CONTROL

17-19

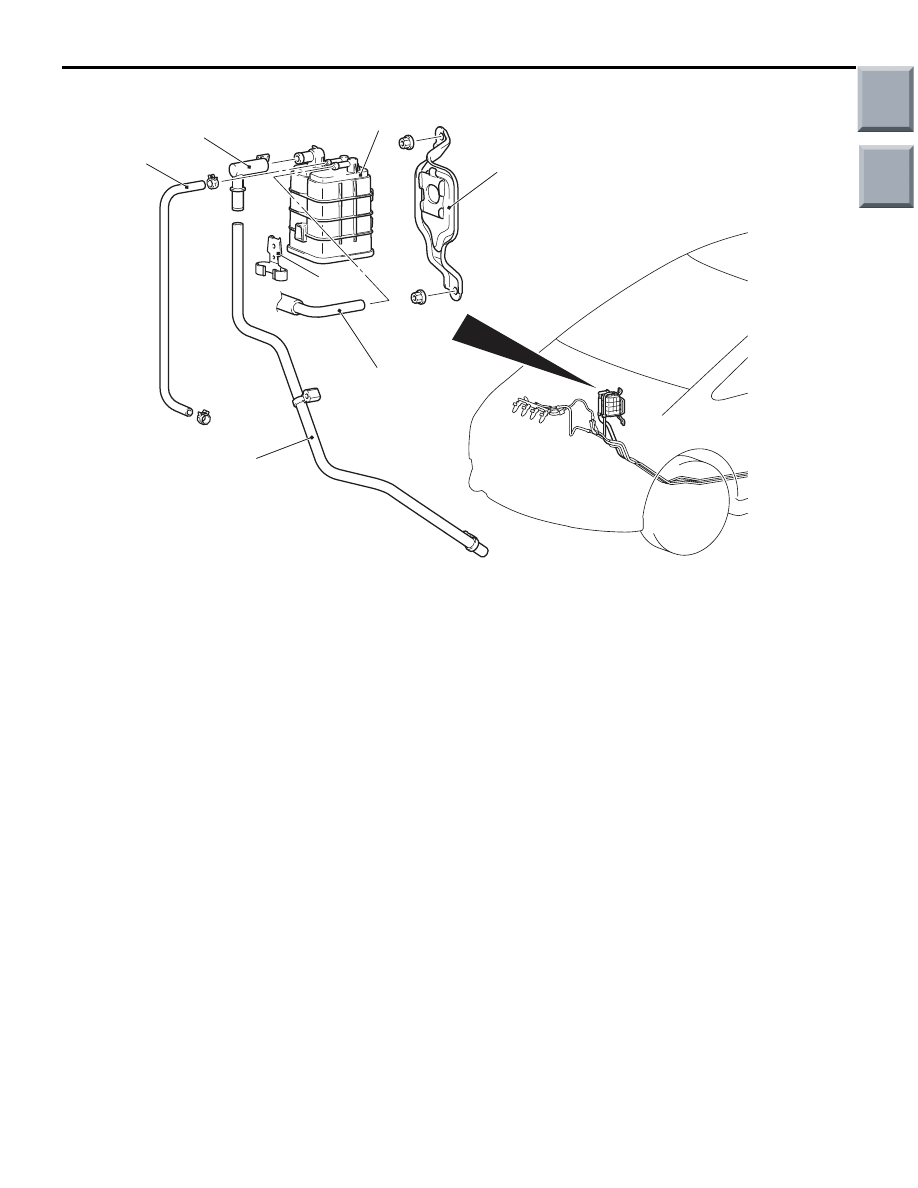

<From Jun. 2006 models>

AC600433AB

1

2

3

4

5

7

6

Removal steps

1.

Purge hose connection

2.

Vapour hose

3.

Vent connector

4.

Vapour hose

5.

Canister

6.

Clamp

7.

Canister bracket

EXHAUST GAS RECIRCULATION (EGR) VALVE

GENERAL INFORMATION (EGR SYSTEM)

<4A9-CVT>

M1173005200822

The exhaust gas recirculation (EGR) system lowers

the nitrogen oxide (NOx) emission level.

When the air/fuel mixture combustion temperature is

high, a large quantity of nitrogen oxides (NOx) is

generated in the combustion chamber.

Therefore, this system recirculates part of emission

gas from the exhaust port of the cylinder head to the

combustion chamber through the inlet manifold to

decrease the air/fuel mixture combustion tempera-

ture, resulting in reduction of NOx.

The EGR flow rate is controlled by the EGR valve so

as not to decrease the driveability.

OPERATION

The EGR valve is being closed and does not recircu-

late exhaust gases under one of the following condi-

tions.

Otherwise, the EGR valve is opened and recirculates

exhaust gases.

• The engine coolant temperature is low.

• The engine is at idle.

• The throttle valve is widely opened.

Removal steps (Continued)

Main

Index

Group

TOC