Mitsubishi Colt Ralliart. Manual - part 102

ON-VEHICLE SERVICE

MULTIPORT FUEL INJECTION (MPI) <4A9>

13A-362

ENGINE COOLANT TEMPERATURE

SENSOR CHECK

M1131003101156

CAUTION

Be careful not to touch the connector (resin sec-

tion) with the tool when removing and installing.

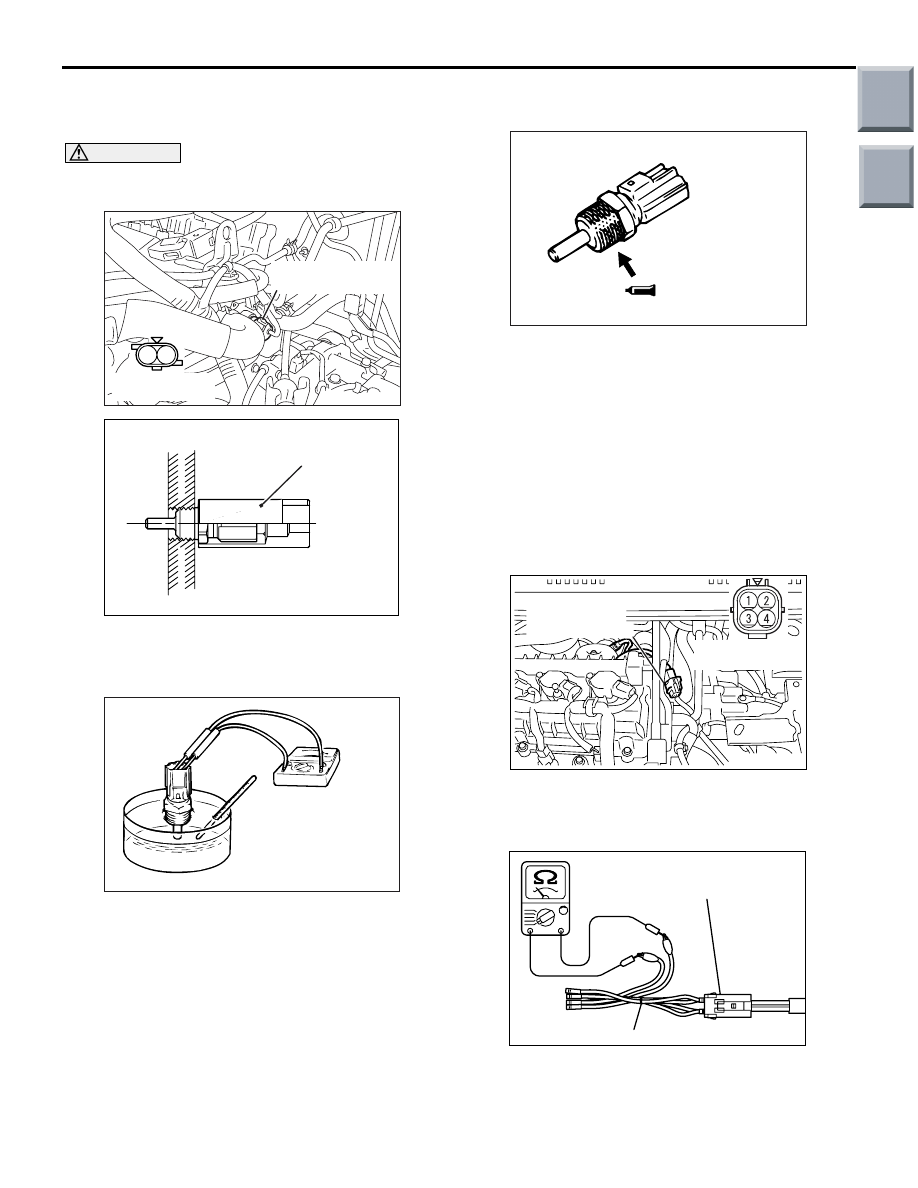

1. Remove the engine coolant temperature sensor

using coolant temperature sensor wrench, special

tool (MB992042).

2. With temperature sensing portion of engine

coolant temperature sensor immersed in hot

water, check resistance.

Standard value:

14

− 17 kΩ (at −20°C)

5.1

− 6.5 kΩ (at 0°C)

2.1

− 2.7 kΩ (at 20°C)

0.9

− 1.3 kΩ (at 40°C)

0.48

− 0.68 kΩ (at 60°C)

0.26

− 0.36 kΩ (at 80°C)

3. If the resistance deviates from the standard value

greatly, replace the sensor.

4. Apply sealant to threaded portion.

Specified sealant:

LOCTITE 262 or equivalent

5. Tighten the engine coolant temperature sensor to

the specified torque, using coolant temperature

sensor wrench, special tool (MB992042)

Tightening torque: 29

± 10 N⋅m

OXYGEN SENSOR CHECK

M1131005001627

OXYGEN SENSOR (FRONT)

1. Disconnect the oxygen sensor connector and

connect the special tool Test harness (MB991658)

to the connector on the oxygen sensor side.

2. Make sure that there is continuity (5

− 30 Ω at

20

°C) between terminal No. 3 and No. 4 on the

oxygen sensor connector.

AK402201

1 2

Engine coolant

temperature sensor

AC

Equipment side

connector

AK503116 AC

MB992042

AKX01622

AKX01623AD

AK402203

AC

Equipment side

connector

Oxygen sensor

(front) connector

AK101798

MB991658

AG

Oxygen sensor

side connector

Main

Index

Group

TOC