Mitsubishi Canter (FE, FG). Manual - part 24

96

6 Modifications to the basic vehicle

6.9 Mounting equipment on the side rail

MITSUBISHI FUSO body/equipment mounting directives for FE, FG Issue date: 06. 07. 2012

!

Only print out complete sections from the current version

i

6.9 Mounting equipment on the side rail

6.9.1

Mounting equipment on the side rail

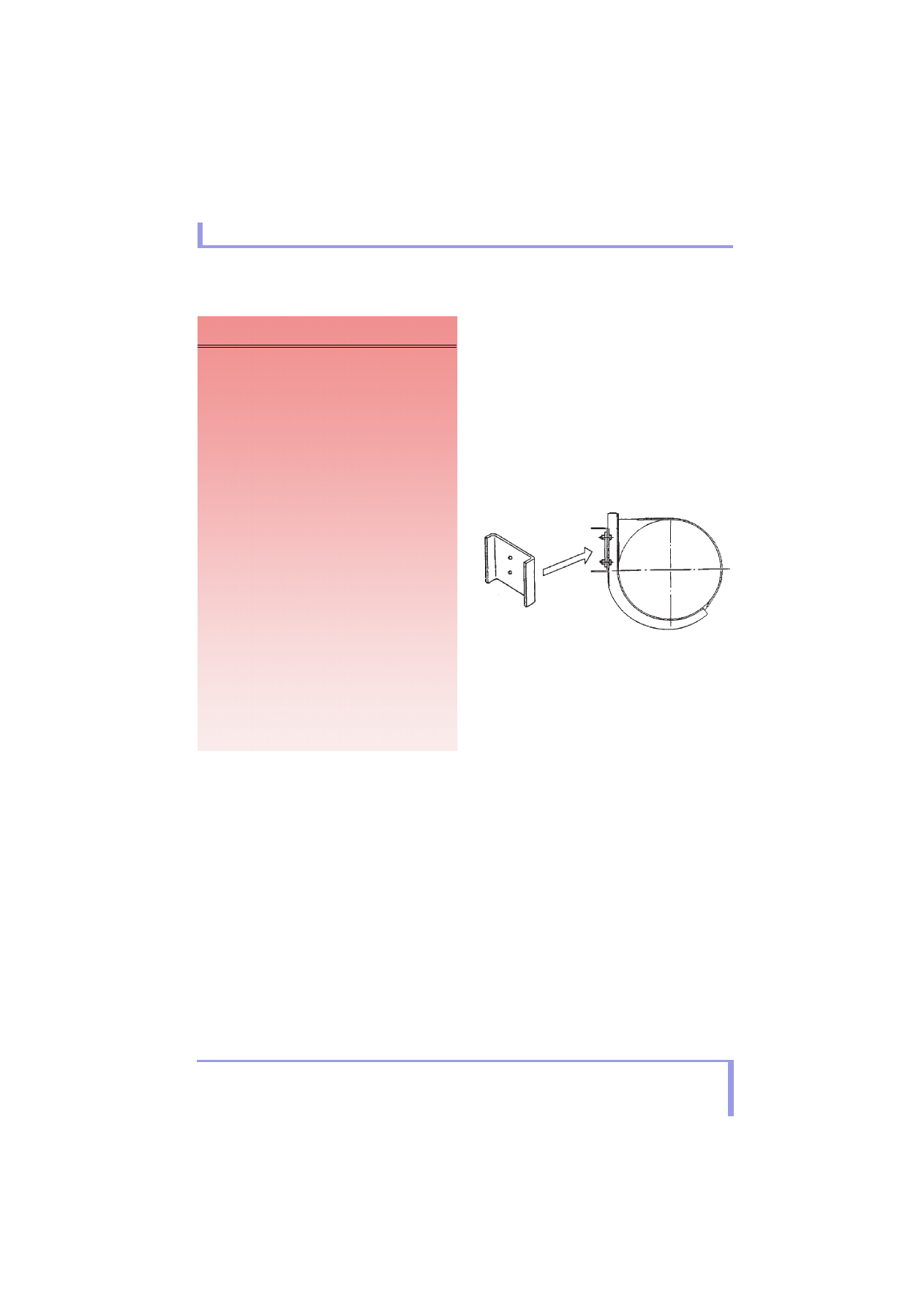

• Attach a stiffener to the inside of the side rail as

shown in Fig. 1 when installing bolts to support

heavy components on the side rail overhang. This

will prevent cracks in the frame due to resonance

of the component if the static load caused by the

weight of the component exceeds 100 kg {220 lb}

of force for each bolt.

Example:

• As a rule, avoid attaching additional equipment

together with components (fuel tank, battery, etc.)

which are already installed to the frame side.

When this is absolutely necessary, increase the

size of the bolts, or the number of bolt locations, to

decrease the stress on each bolt.

a

Risk of accident

The use of parts, assemblies or conversion parts

and accessories which have not been approved

may jeopardize the safety of the vehicle.

Before installing any attachments, special-purpose

bodies, equipment or carrying out any

modifications to the basic vehicle and/or its

assemblies, you must read the relevant sections of

the vehicle Owner's Manual, as well as the

operating and assembly instructions issued by the

manufacturer of the accessories and items of

optional equipment.

You could otherwise fail to recognize dangers,

which could result in injury or death.

Official acceptance by public testing bodies or

official approval does not rule out safety hazards.

All federal, state, and local regulations and codes

and registration requirements must be complied

with.

Fig. 1

Holder panel