Mitsubishi Canter (FE, FG). Manual - part 21

84

6 Modifications to the basic vehicle

6.3 Drilling work on the vehicle frame

MITSUBISHI FUSO body/equipment mounting directives for FE, FG Issue date: 06. 07. 2012

!

Only print out complete sections from the current version

i

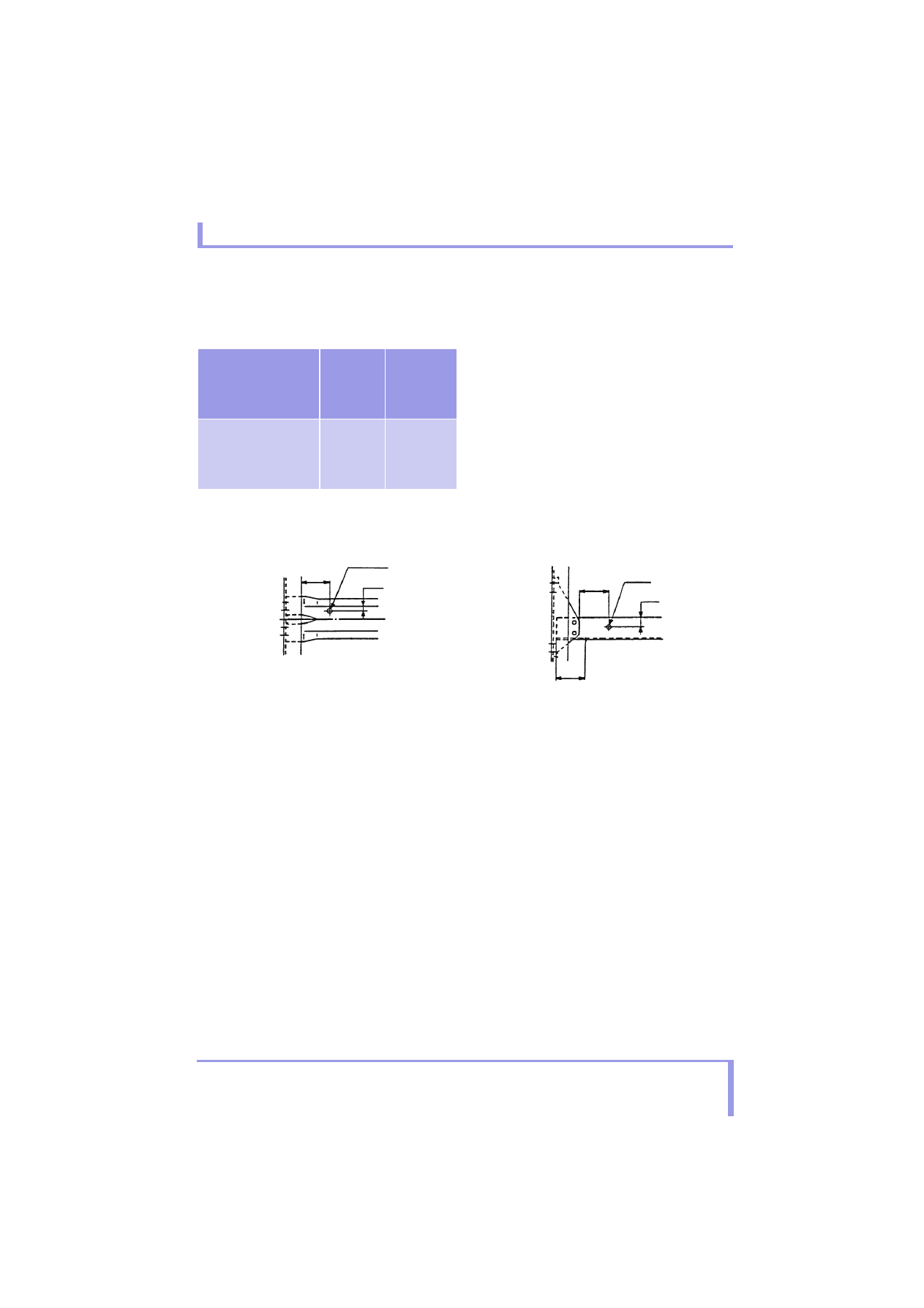

Drilling work on the crossmembers

• The holes and distances between the holes should

conform to the values specified in the chart below.

Note*: Maintain the dimensions of previously drilled

holes.

• Holes should be more than 100 mm {3.94 in.} away

from the end of the side rail flange or the end of the

gusset.

• Holes in the web of the channel type crossmember

should be 50 mm {1.97 in.} min. from the end of the

crossmember. (Refer to Fig. 2)

• Holes in the flange should be more than 25 mm

{0.98 in.} from the end.

• Holes should be drilled more than 20 mm {0.79 in.}

from the curved part of the flange.

Crossmember type

Hole

diameter

Center-to-

center

distance of

holes

• Alligator type

(see Fig. 1)

• Channel type

(see Fig. 2)

9 mm

{0.35 in.}

max.

30 mm {1.18

in.}* min.

Alligator type

Fig. 1

1

2

3

4

5

6

7

Channel type

Fig. 2

1

100 mm {3.94 in.} min

2

DIA 9 mm {0.35 in.} max

3

25 mm {0.98 in.} min

4

100 mm {3.94 in.} min

5

DIA 9 mm {0.35 in.} max

6

25 mm {0.98 in.} min

7

50 mm {1.97 in.} min (Web surface)