Mitsubishi Canter (FE, FG). Manual - part 8

32

3 Planning of bodies

3.8 Duonic

®

i

MITSUBISHI FUSO body/equipment mounting directives for FE, FG Issue date: 06. 07. 2012

!

Only print out complete sections from the current version

3.8.3

Initialization of DUONIC

®

system

Initializing the DUONIC

®

system stores the GSU (gear

shift unit) gear position, road surface grade zero point

correction value, clutch fill time learning value and

clutch torque learning value in the memory of the TCU.

It must be performed after ANY type of transmission-

related service.

If any abnormality occurs during normal running, it

may be cleared by initialization. Some kinds of body

equipment work to the vehicle can cause an error in

road surface grade recognition. To prevent this, be

sure to initialize the DUONIC

®

system under the

following conditions after body equipment work.

Conditions for initialization

Check the following before initialization.

(a) The engine electronic control unit and

DUONIC

®

electronic control unit (TCU) are

finished with flashing (programming) and

coding (in case of a change in tire size or final

ratio). For details, contact a MITSUBISHI FUSO

service center.

(b) To compute the road grade zero point

correction value, make sure that the vehicle is

in the following state:

• Standing still, brake released, on a flat surface

such that the vehicle remains stationary

without drifting forward or backward

• Equipped with specified wheels with the tires

filled to correct pressures.

• Cab tilt locked (a G sensor is provided in the

cab.)

(c) For learning the clutch torque, units powered by

the engine, such as the following, must be

stopped:

• Air conditioner

• Load for equipment (compressor for refrig-

erator, etc.)

• Exhaust brake

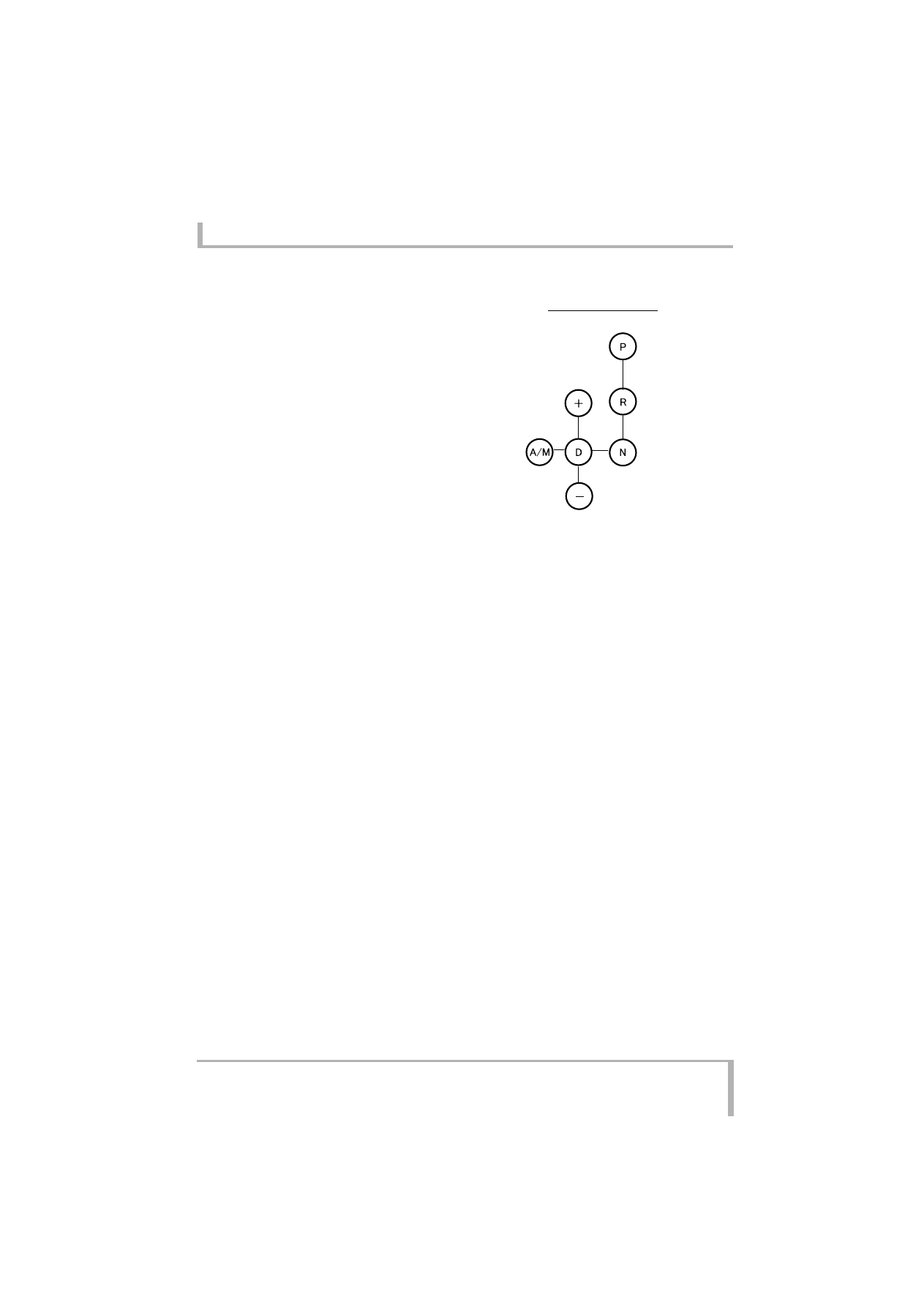

Change lever pattern