Mitsubishi 380. Manual - part 828

SRS CONTROL UNIT (SRS-ECU)

SUPPLEMENTAL RESTRAINT SYSTEM (SRS)

52B-236

INSTALLATION SERVICE POINTS

.

>>A<< SRS-ECU INSTALLATION

WARNING

The SRS may not activate if the SRS-ECU is not

installed properly, which could result in serious injury

or death to the vehicle's driver or front passenger.

Install the SRS-ECU with 10mm (3/8inch) slide head handle

and 10mm (3/8inch) socket wrench.

.

>>B<< POST-INSTALLATION INSPECTION

1. Reconnect the negative (

−) battery cable.

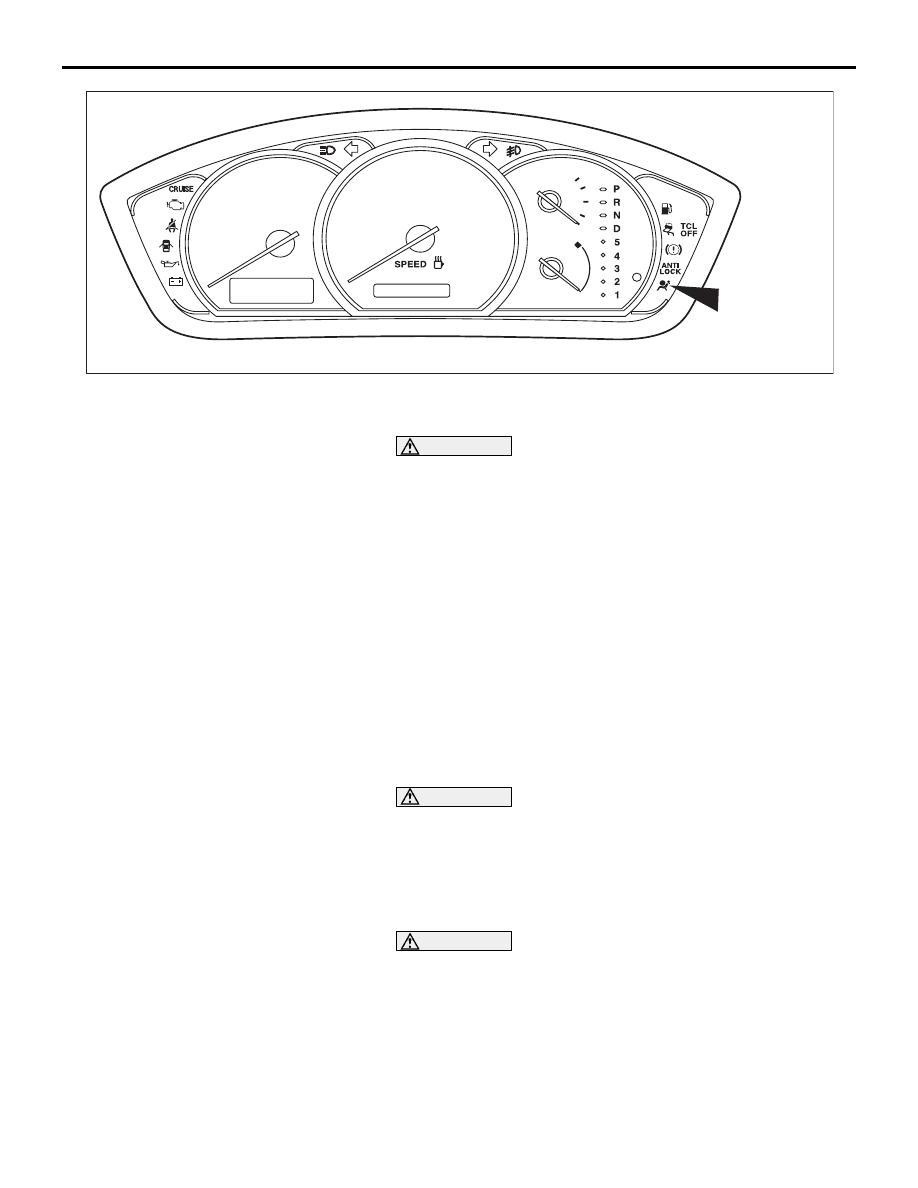

2. Turn the ignition switch to the "ON" position.

3. Does the "SRS" warning lamp illuminate for approximately

seven seconds, and then go out?

4. If yes, the SRS system is functioning properly. If not, refer to

.

INSPECTION

M1524002200357

WARNING

If a dent, crack, deformation or rust is discovered,

replace the SRS-ECU with a new one.

• Check the SRS-ECU and brackets for dents, cracks or

deformation.

• Check the SRS-ECU connector for damage, and the termi-

nals for deformation.

WARNING

[SRS is a safety related item, therefore there shall be no

attempt to repair any component or wiring harness related

to SRS]

NOTE: Refer to

for inspection of SRS-ECU for other

than physical damage.

35DB113A

SRS

WARNING

LAMP