Mitsubishi 380. Manual - part 558

MULTIPORT FUEL INJECTION (MFI) DIAGNOSIS

MULTIPORT FUEL INJECTION (MFI)

13A-324

DTC P0223: Throttle Position Sensor (Sub) Circuit High Input.

.

CIRCUIT OPERATION

• A 5-volt power supply is applied on the throttle

position sensor (sub) power terminal (terminal

No. 3) from the ENGINE-ECU(terminal No. 10).

The throttle position sensor (sub) outputs a volt-

age from (terminal No. 5) to the

ENGINE-ECU(terminal No. 57).

The ground terminal (terminal No. 2) is grounded

with ECU (terminal No. 27).

.

TECHNICAL DESCRIPTION

• The throttle position sensor (sub) outputs voltage

which corresponds to the throttle valve opening

angle.

• The ECU checks whether the voltage is within a

specified range.

.

DTC SET CONDITIONS

Check Conditions

• Ignition switch is "ON" position.

• TPS is normal.

Judgement Criteria

• MIL is actvated immediately.

• Vehicle in Limp home - Engine speed limited to

1500rpm.

.

EOBD DRIVE CYCLE PATTERN

None.

.

TROUBLESHOOTING HINTS (The most

likely causes for this code to be set are:)

• Throttle position sensor failed.

• Short circuit to 5 Volts in throttle position sensor

(sub) circuit.

• Harness or connector damage

• Refer to component locations GROUP-

• Refer to configuration diagrams GROUP-

• Refer to circuit diagrams GROUP-

DIAGNOSIS

Required Special Tools:

• Diagnostic Tool (MUT-III Sub Assembly)

• MB991824: V.C.I.

• MB991827: USB Cable

• MB991910: Main Harness A

• MB992044: Power Plant ECU Check Harness

03DB180A

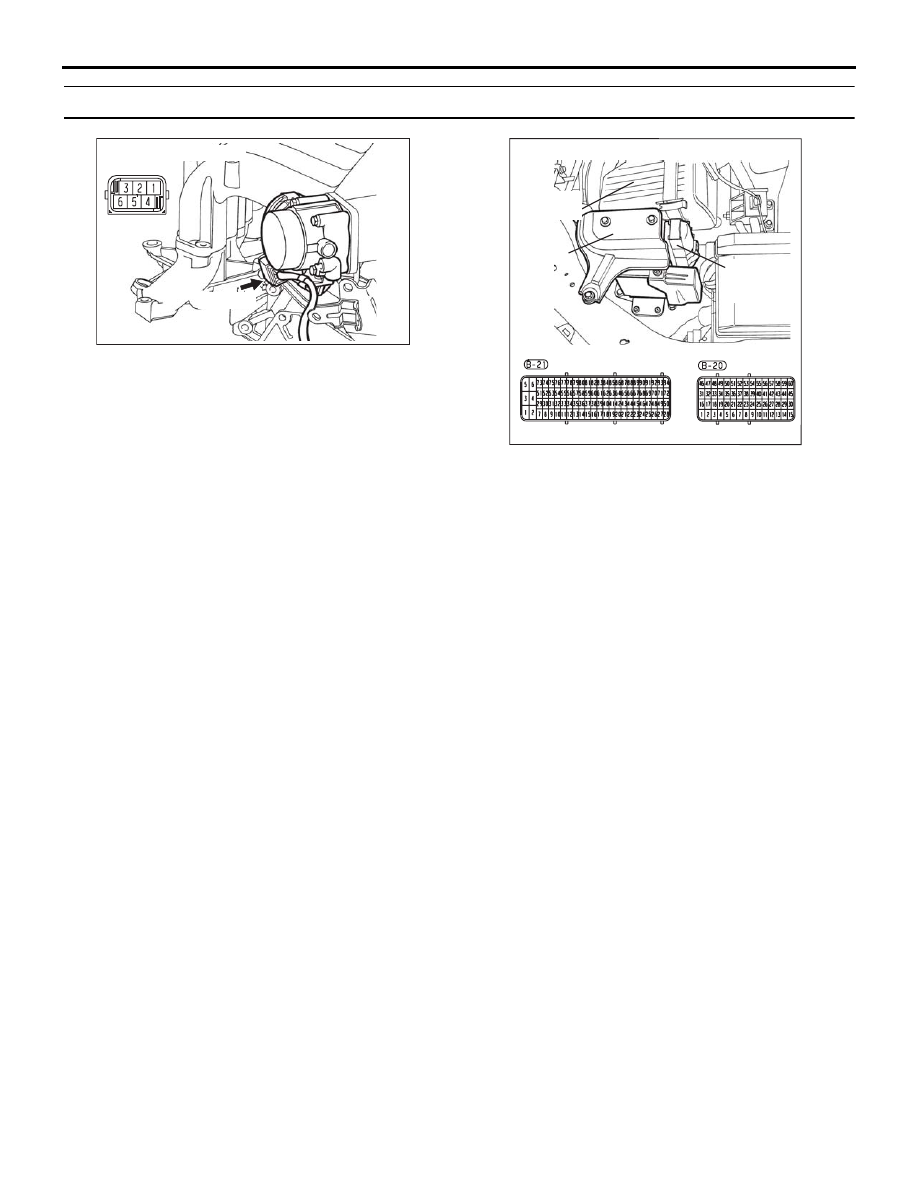

CONNECTOR: B-06

B-06 (B)

16DB400A

COVER

ENGINE

CONTROL

UNIT

AIR

CLEANER