Mitsubishi 380. Manual - part 556

MULTIPORT FUEL INJECTION (MFI) DIAGNOSIS

MULTIPORT FUEL INJECTION (MFI)

13A-316

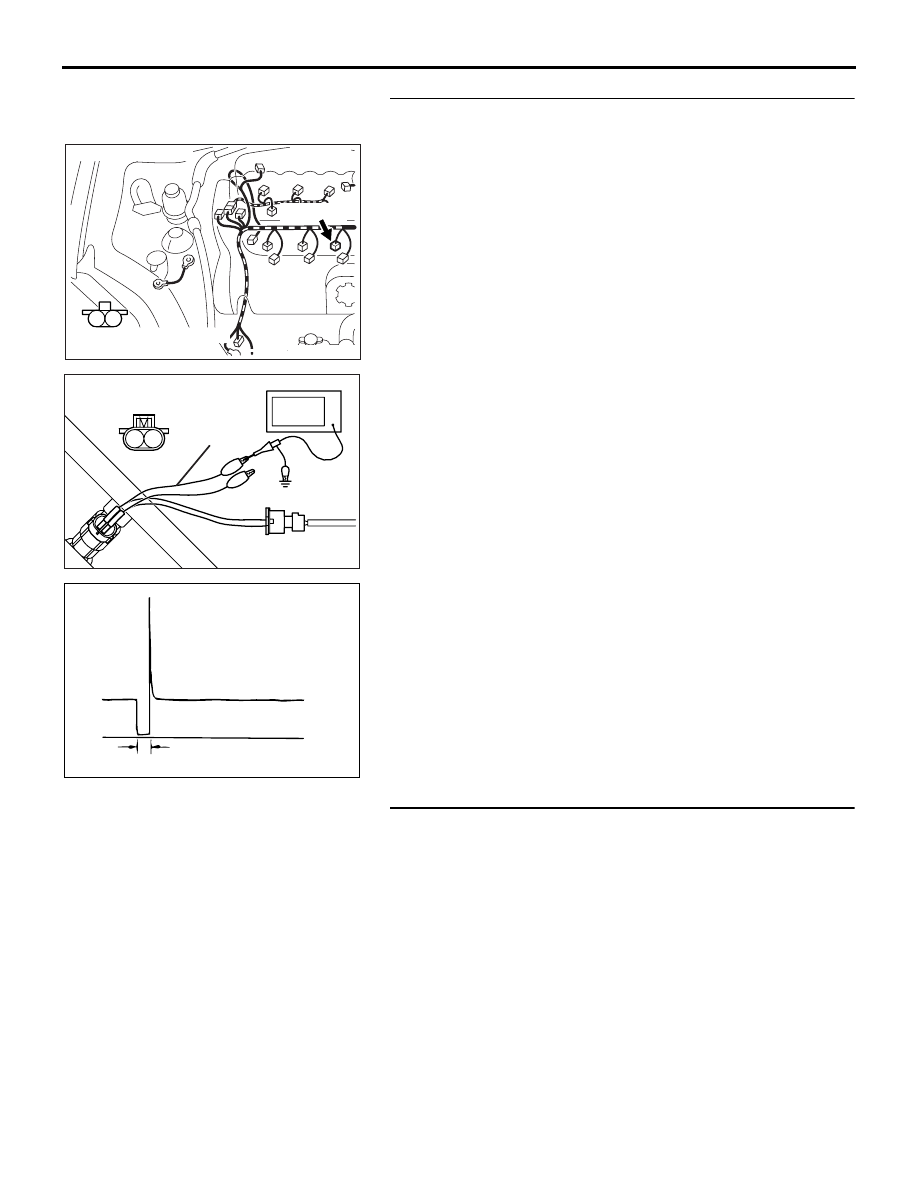

STEP 9. Using the oscilloscope, check the No. 6 cylinder

injector.

(1) Disconnect the No. 6 cylinder injector connector B-26 and

connect the test harness special tool (MB991658) between

the separated connectors. (All terminals should be

connected)

(2) Connect the oscilloscope probe to the injector side

connector terminal No. 2.

NOTE: When measuring with the ECU side connector, dis-

connect the all ECU connectors and connect check harness

special tool (MB992044) between the separated connec-

tors. Then connect an oscilloscope probe to the check har-

ness connector terminal No. 17.

(3) Start the engine and run at idle.

(4) Measure the waveform.

• The waveform should show a normal pattern similar to

the illustration.

(5) Turn the ignition switch to the "LOCK" (OFF) position.

Q: Is the waveform normal?

YES : It can be assumed that this malfunction is intermittent.

Refer to GROUP 00, How to Use

Troubleshooting/Inspection Service Points

− How to

Cope with Intermittent Malfunctions

.

NO : Replace the ECU. Then go to Step 10.

STEP 10. Test the EOBD drive cycle.

(1) Carry out a test drive with the drive cycle pattern. Refer to

Diagnostic Function

− EOBD Drive Cycle −

(2) Check the diagnostic trouble code (DTC).

Q: Is DTC P0206 set?

YES : Retry the troubleshooting.

NO : The inspection is complete.

AK303116

M

1

2

CONNECTOR: B-26

B-26 (GR)

HARNESS CONNECTOR:

COMPONENT SIDE

AB

AK302166

1 2

INJECTOR

CONNECTOR

MB991658

OSCILLOSCOPE

AB

AKX01557 AB

A

NORMAL WAVEFORM

A:INJECTOR DRIVE TIME