Mitsubishi 380. Manual - part 559

MULTIPORT FUEL INJECTION (MFI) DIAGNOSIS

MULTIPORT FUEL INJECTION (MFI)

13A-328

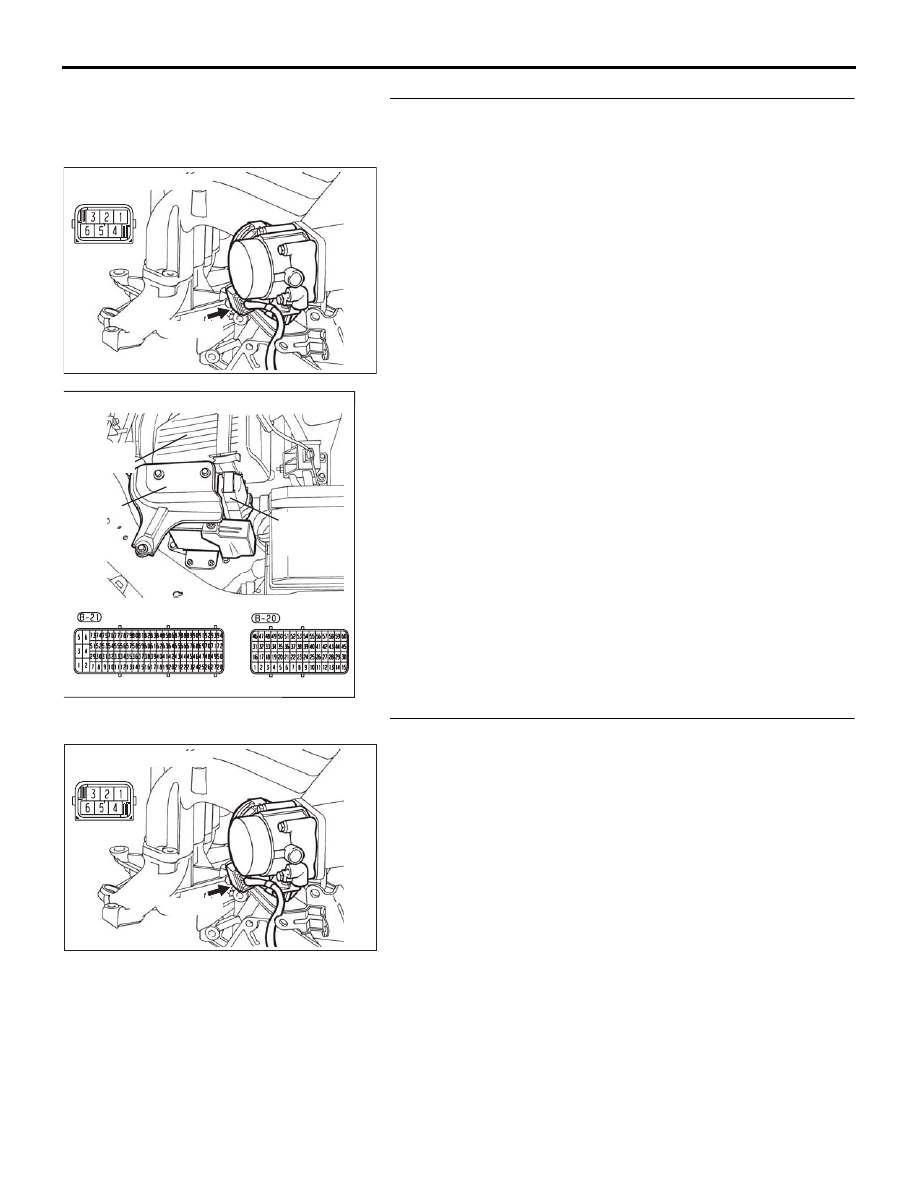

STEP 6. Check for short circuit to 5-Volts and harness

damage between throttle position sensor connector B-06

(terminal No. 5) and ECU connector B-20 (terminal No. 57).

Q: Is the harness wire in good condition?

YES : Go to Step 7.

NO : Repair or repalce it. Then go to Step 8.

STEP 7. Replace the throttle body assembly.

(1) Replace the throttle body assembly.

(2) Turn the ignition switch to the "ON" position.

(3) After the DTC has been deleted, read the DTC again.

(4) Turn the ignition switch to the "LOCK" (OFF) position.

Q: Is DTC P0223 set?

YES : Retry the troubleshooting.

NO : The inspection is complete.

03DB180A

CONNECTOR: B-06

B-06 (B)

16DB400A

COVER

ENGINE

CONTROL

UNIT

AIR

CLEANER

03DB180A

CONNECTOR: B-06

B-06 (B)