Mitsubishi 380. Manual - part 511

MULTIPOINT FUEL INJECTION (MPI) DIAGNOSIS

MULTIPOINT FUEL INJECTION (MPI)

13A-136

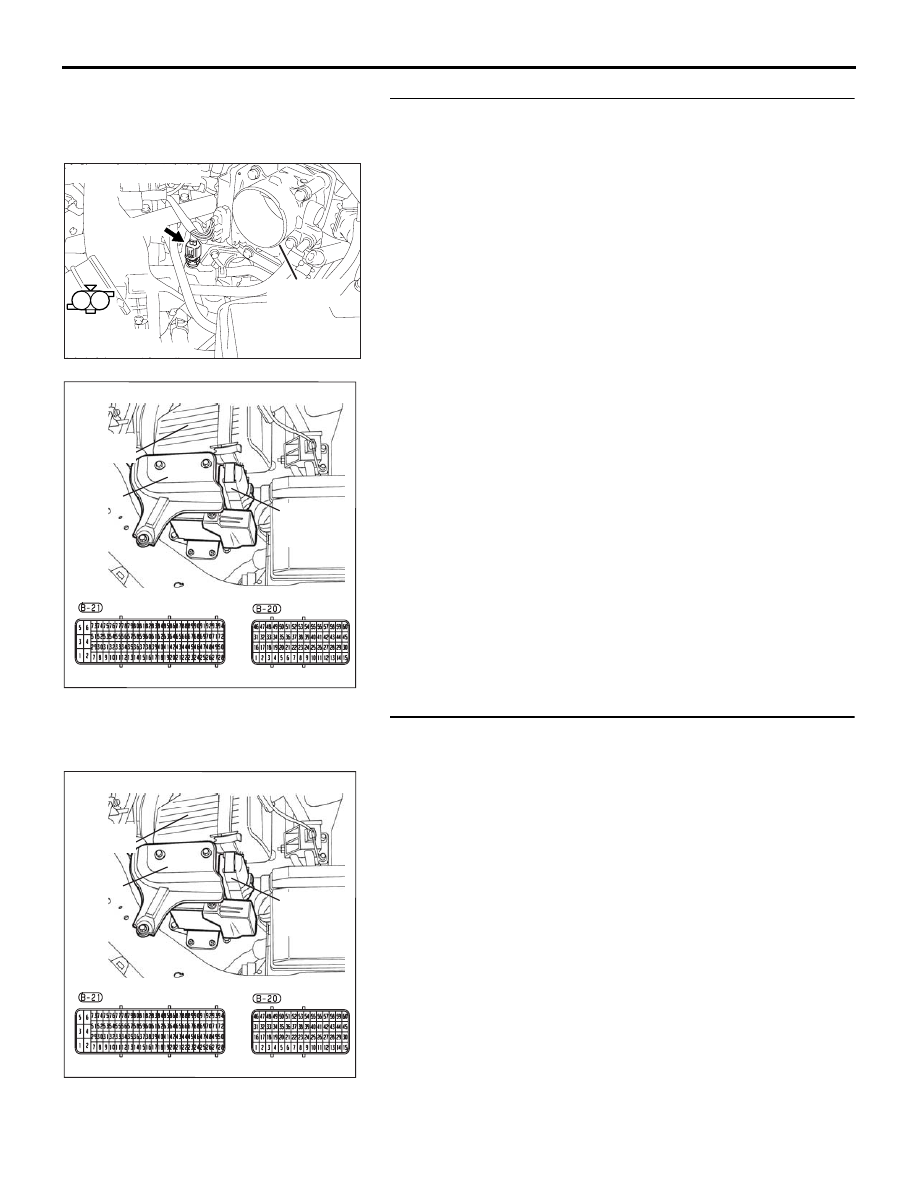

STEP 3. Check for short circuit to ground between engine

coolant temperature sensor connector B-104 (terminal No.

1) and ENGINE-ECU connector B-20 (terminal No. 56).

Q: Is the harness wire in good condition?

YES : Go to Step 4.

NO : Repair it. Then go to Step 7.

STEP 4. Check harness connector B-20 at ENGINE-ECU for

damage.

Q: Is the harness connector in good condition?

YES : Go to Step 5.

NO : Repair or replace it. Refer to GROUP 00E, Harness

Connector Inspection

. Then go to Step 7.

1

2

AK303037

HARNESS

CONNECTOR:

COMPONENT SIDE

CONNECTOR: B-104

AB

B-104 (B)

THROTTLE

BODY

16DB400A

COVER

ENGINE

CONTROL

UNIT

AIR

CLEANER

16DB400A

COVER

ENGINE

CONTROL

UNIT

AIR

CLEANER