Mitsubishi 380. Manual - part 472

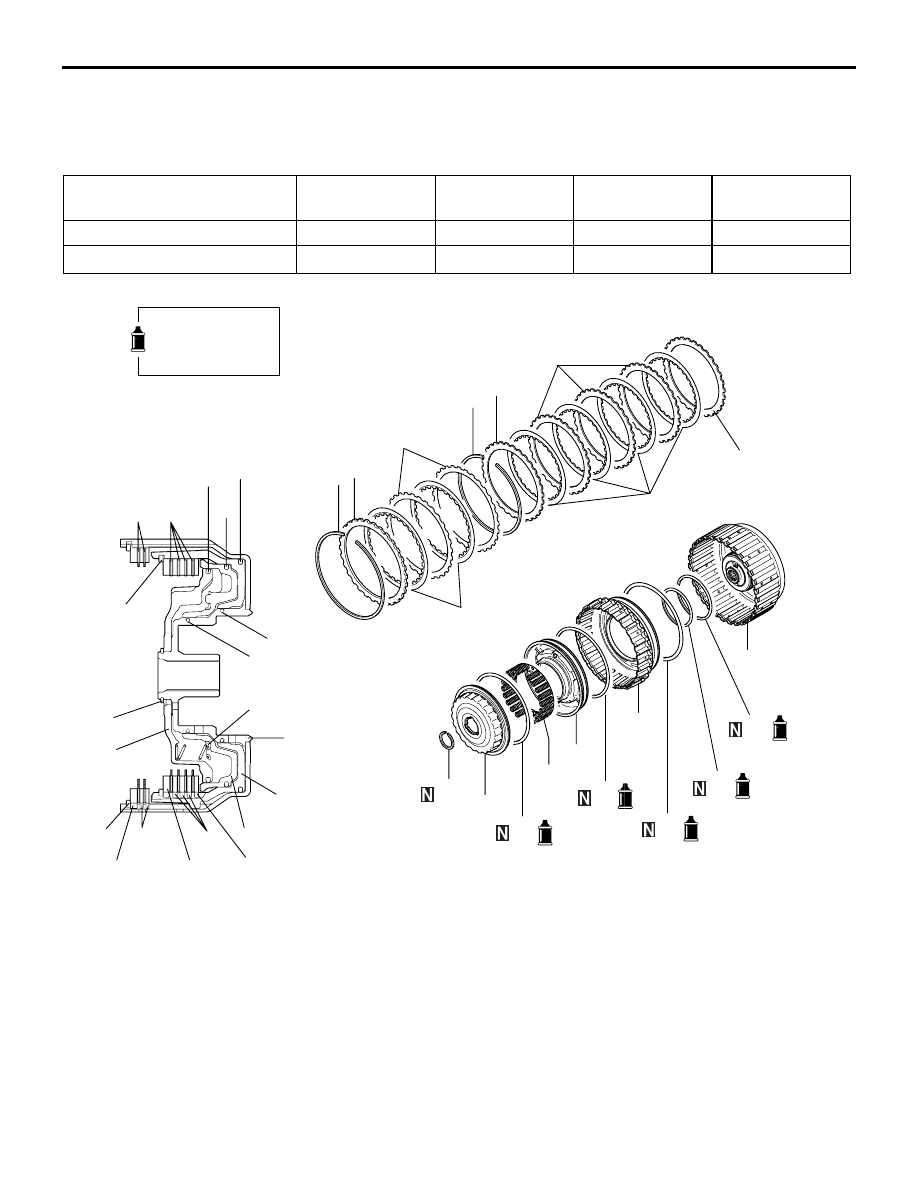

REVERSE AND OVERDRIVE CLUTCH

AUTOMATIC TRANSMISSION OVERHAUL

23B-48

REVERSE AND OVERDRIVE CLUTCH

DISASSEMBLY AND REASSEMBLY

M1233021200256

Number of clutch discs and plates

Pressure plate

Clutch disc

Clutch plate

Clutch reaction

plate

Over drive clutch

1

4

3

1

Reverse clutch

−

2

2

1

AKX01127AE

Apply automatic

transmission fluid

to all moving parts

before installation.

13

10

15

11

12

14

6

8

3

2

2

1

9

5

4

7

19

18

20

16

9

8

6

1

17

3

7

18

10

11

19

13

20

16

17

15

14

12

5

Disassembly steps

>>

G

<<

1.

Snap ring

>>

F

2.

Clutch reaction plate

>>

F

3.

Clutch disc

>>

F

4.

Clutch plate

>>

E

5.

Snap ring

>>

D

<<

6.

Clutch reaction plate

>>

D

<<

7.

Clutch disc

>>

D

<<

8.

Clutch plate

>>

D

<<

9.

Pressure plate

<<

A

>>

>>

C

<<

10. Snap ring

11. Spring retainer

>>

A

12. D-ring

13. Return spring

14. Overdrive clutch piston

>>

A

15. D-ring

>>

B

16. Reverse clutch piston

>>

A

17. D-ring

>>

A

18. D-ring

>>

A

19. D-ring

20. Reverse clutch retainer

Disassembly steps ( つづき )