Mitsubishi 380. Manual - part 470

AK501914

TRANSMISSION

AUTOMATIC TRANSMISSION OVERHAUL

23B-40

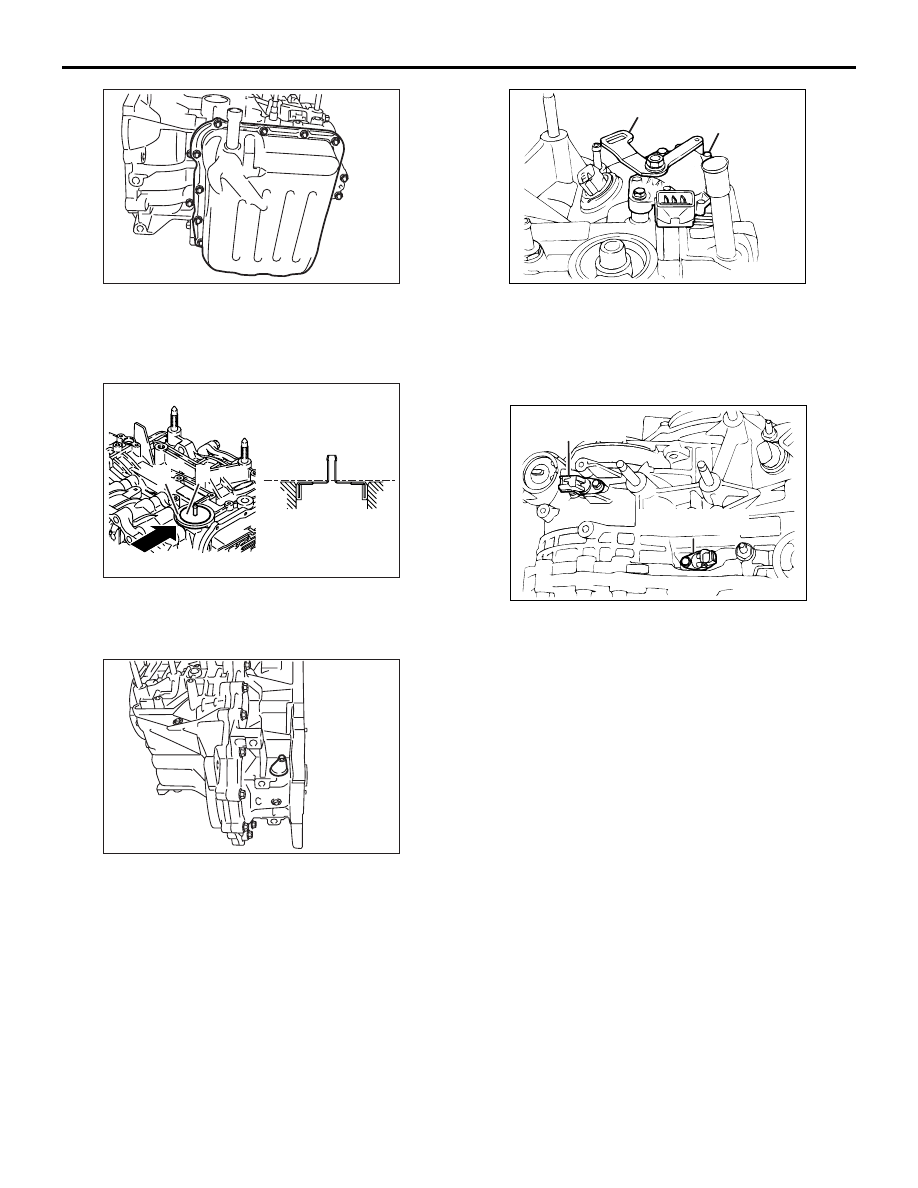

88.Install the valve body cover, and then tighten its

mounting bolts to the specified torque of 11

± 1

N

⋅m.

AK203140 AE

A

A

B

B

89.Press Face "A" of the air breather to be on the

same plane as the Face "B" of the transmission

case as shown in the illustration.

AK300220

90.Install the sealing cap and tighten the bolt to the

specified torque of 5.0

± 1.0 N⋅m. <Type with

sealing cap>

AK202096

Manual control lever

Inhibitor switch

AB

91.Install the inhibitor switch and tighten the bolt to

the specified torque of 11

± 1 N⋅m.

92.Install the manual control lever and tighten the nut

to the specified torque of 22

± 3 N⋅m.

AK202095AB

Output shaft

speed sensor

Input shaft

speed sensor

93.Install the input shaft speed sensor and output

shaft speed sensor and tighten the bolt to the

specified torque of 11

± 1 N⋅m.

94.Apply ATF on the both sides of the new gasket

and threads of the eyebolts, and then tighten to

the specified torque of 24

± 3 N⋅m.

95.Tighten the oil cooler feed pipe clamp bolt to the

specified torque of 11

± 1 N⋅m.

96.Install the oil dipstick.

97.Install the control cable support brackets to the

specified torque of 23

± 3 N⋅m.

98.Install the harness bracket to the specified torque

of 11

± 1 N⋅m.

99.Install the roll stopper brackets to the specified

torque of 70

± 10 N⋅m.