Mitsubishi 380. Manual - part 471

AK202226

MB991445

AB

TRANSMISSION

AUTOMATIC TRANSMISSION OVERHAUL

23B-44

3. Use the special tools Bush remover and installer

(MB991445) to press the differential bearing outer

race into the torque converter housing.

AK202103

4. Install the converter housing on the transmission

case without applying FIPG. Tighten the mounting

bolts to the specified torque of 48

± 6 N⋅m.

5. Remove the bolts and converter housing, and

take out the crushed plastigage.

6. If the plastigages have not crushed, replace the

spacer with a thicker one and repeat steps 3 to 5.

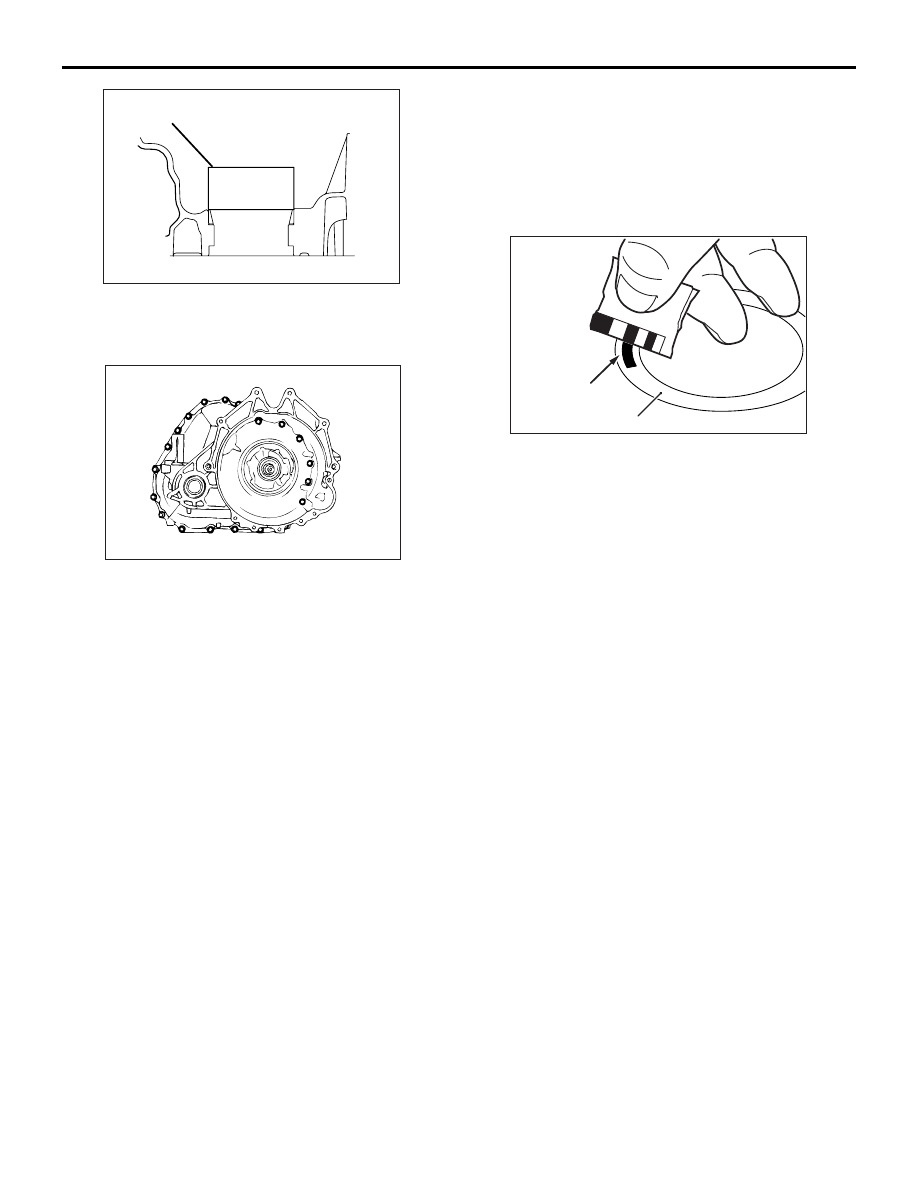

AK402081

Plastigage

Spacer

AB

7. Measure the width of the crushed plastigage at its

widest part using a scale printed on the plastigage

package, and then select a spacer that will

provide the standard value.

Spacer thickness: (T3

− 0.045 mm) to (T3 −

0.105 mm)

T3: The crushed plastigage thickness mm

Standard value: 0.045

− 0.105 mm