Mitsubishi 380. Manual - part 317

MAINTENANCE SERVICE

GENERAL

00-46

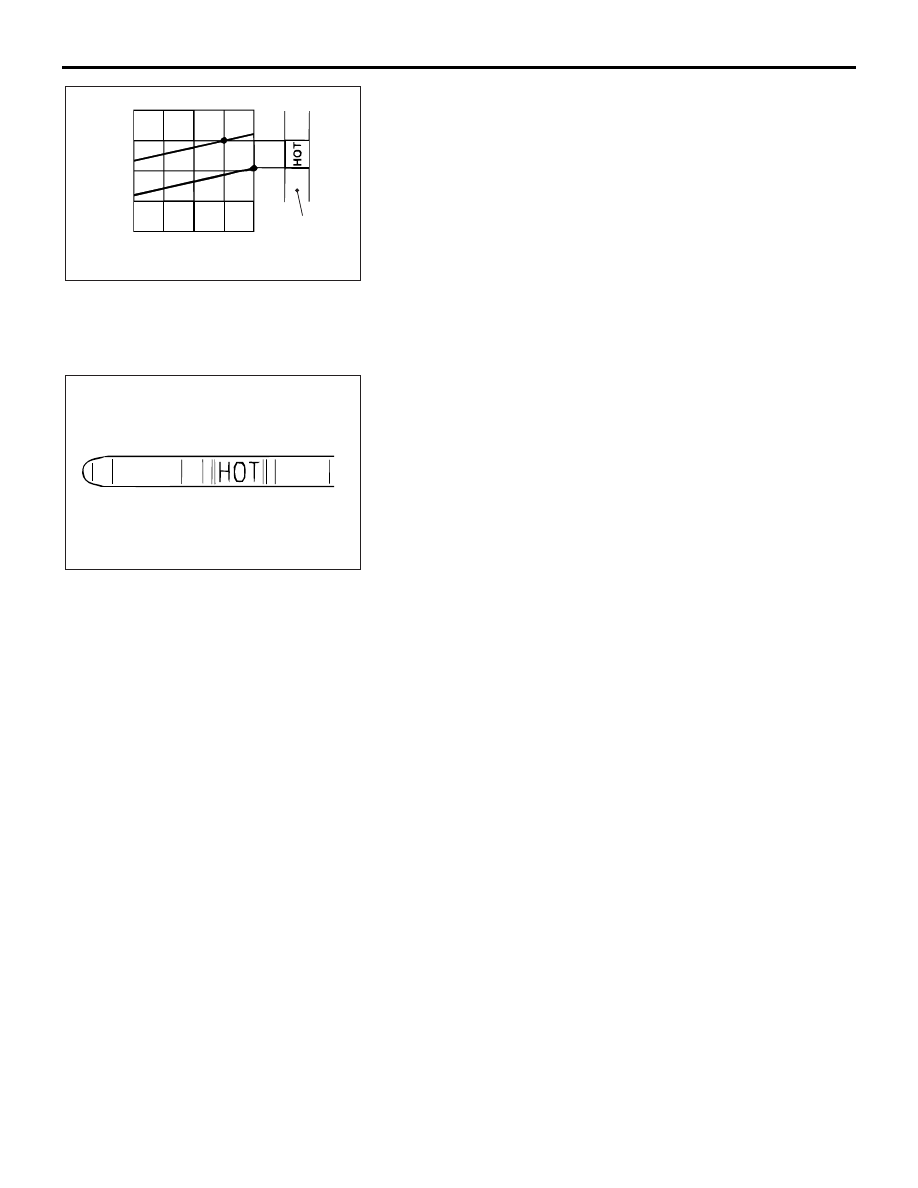

NOTE: If it takes some amount of time until the transmission

fluid reaches its normal operating temperature [70

− 80°C

(158

− 176°F)], check the transmission fluid level by refer-

ring to the left diagram.

2. Park the vehicle on a level surface.

3. Move the selector lever through all positions to fill the torque

converter and the hydraulic circuits with fluid, and then move

the selector lever to the "N" position.

4. After wiping off any dirt around the dipstick, remove the

dipstick and check the condition of the transmission fluid.

NOTE: If the transmission fluid smells as if it is burnt, it

means that the transmission fluid has been contaminated by

fine particles from the bushings and friction materials. Tran-

saxle overhaul and cooler line flushing may be necessary.

5. Check transmission fluid level is at the "HOT" mark on the

dipstick. If the transmission fluid level is less than this, add

DIAMOND ATF SP III until the level reaches the "HOT"

mark.

NOTE: If the transmission fluid level is too low, the oil pump

will draw in air along with the transmission fluid, which will

cause to form bubbles. If the transmission fluid level is too

high, rotating components inside the transaxle will churn the

fluid and air into a foamy liquid. Both conditions (level too

low or too high) will cause the hydraulic pressure to drop,

which will result in late shifting and slipping of the clutches

and brakes.

NOTE: In either case, air bubbles can interfere with normal

valve, clutch, and brake operation. Also, foaming can cause

transmission fluid to escape from the transaxle vent where it

may be mistaken for a leak.

AC005860

80

DIPSTICK

60

40

(176)

(140)

(104)

FLUID TEMPERATURE [˚C (˚F)]

– 30 (– 1.2)

– 20 (– 0.8)

– 10 (– 0.4)

0 (0)

10 (0.4)

FLUID LEVEL [mm (in)]

AB

AC106828AB