Mitsubishi 380. Manual - part 315

MAINTENANCE SERVICE

GENERAL

00-38

5. SPARK PLUGS (REPLACE)

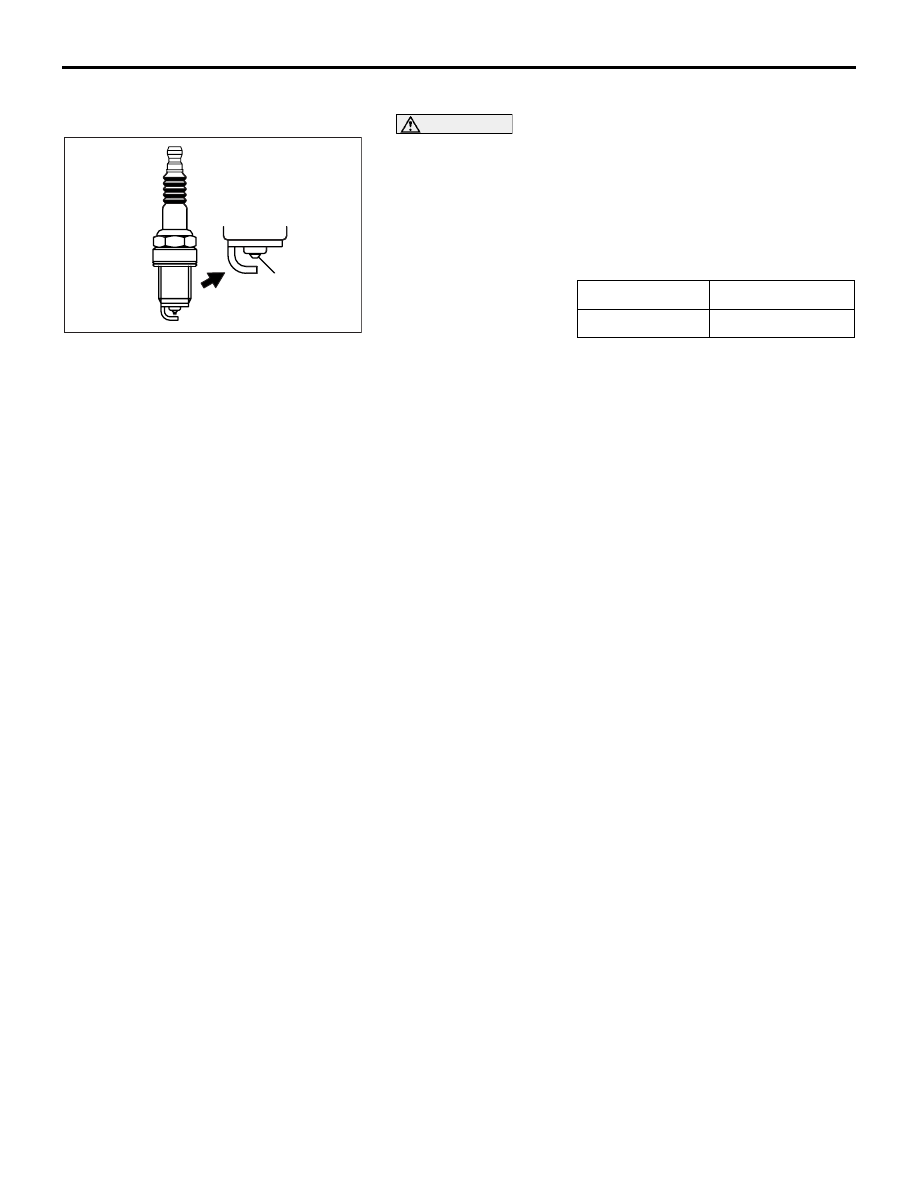

M1001002000346

CAUTION

Iridium plugs are used. Use care not to damage the iridium

tips of the plugs. Do not adjust the spark plug gap.

1. Spark plugs must spark properly to assure proper engine

performance and reduce exhaust emission level. Therefore,

they should be replaced periodically with new ones( Refer to

Maintainence Schedule).

Spark plug type

2. The new plugs should be checked for the proper gap.

Spark plug gap: 1.0

− 1.1 mm

3. Install the spark plugs and tighten to 25

± 5 N⋅m (18 ± 4

ft-lb).

6. TIMING BELT (REPLACE)

M1001002300273

Replace the belt with a new one according to the vehicle main-

tenance schedule to assure proper engine performance.

<3.8L ENGINE>

For removal and installation procedures, refer to GROUP 11C,

Engine Mechanical <3.8L Engine>

− Timing Belt − Removal

and Installation

.

MAKER

3.8L ENGINE

BOSCH

FR8DI30

AKX00383

AKX00383

IRIDIUM TIP

AK