Mitsubishi 380. Manual - part 129

FRONT SEAT ASSEMBLY

INTERIOR

52A-24

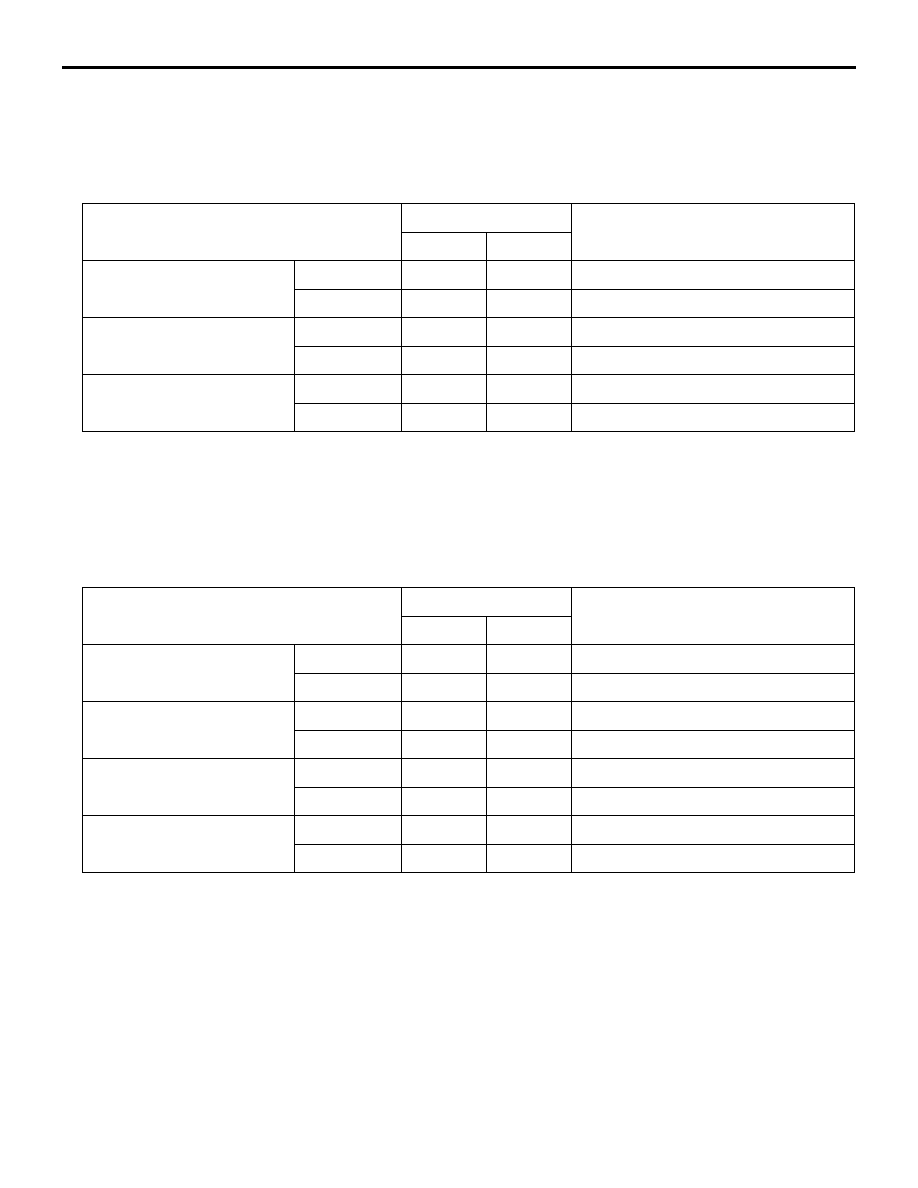

6-WAY TRACK (NON MEMORY)

NOTE: The special tool (Inspection test harness) MB991219

for connector pin contact pressure should be used. The test

probe should never be forcibly inserted, as it may cause a

defective contact.

8 and 10-WAY TRACK (NON MEMORY)

NOTE: The special tool (Inspection test harness) MB991219

for connector pin contact pressure should be used. The test

probe should never be forcibly inserted, as it may cause a

defective contact.

SWITCH POSITION

TEST CONNECTION SPECIFIED CONDITION

SWITCH

MOTOR

REAR LIFT MOTOR

UP

2

1

Less than 2 ohms

DOWN

3

5

Less than 2 ohms

FRONT LIFT MOTOR

UP

1

1

Less than 2 ohms

DOWN

4

5

Less than 2 ohms

TRACK/ SLIDE MOTOR

FORWARD

5

2

Less than 2 ohms

BACK

8

1

Less than 2 ohms

SWITCH POSITION

TEST CONNECTION SPECIFIED CONDITION

SWITCH

MOTOR

REAR LIFT MOTOR

UP

7

1

Less than 2 ohms

DOWN

8

5

Less than 2 ohms

FRONT LIFT MOTOR

UP

6

1

Less than 2 ohms

DOWN

9

5

Less than 2 ohms

TRACK/ SLIDE MOTOR

FORWARD

10

2

Less than 2 ohms

BACK

3

1

Less than 2 ohms

RECLINING MOTOR

FORWARD

4

1

Less than 2 ohms

BACK

2

5

Less than 2 ohms