Mitsubishi Grandis. Manual - part 980

ON-VEHICLE SERVICE

POWER STEERING

37-10

TIE ROD END BALL JOINT TURNING

TORQUE CHECK

M1372001500402

CAUTION

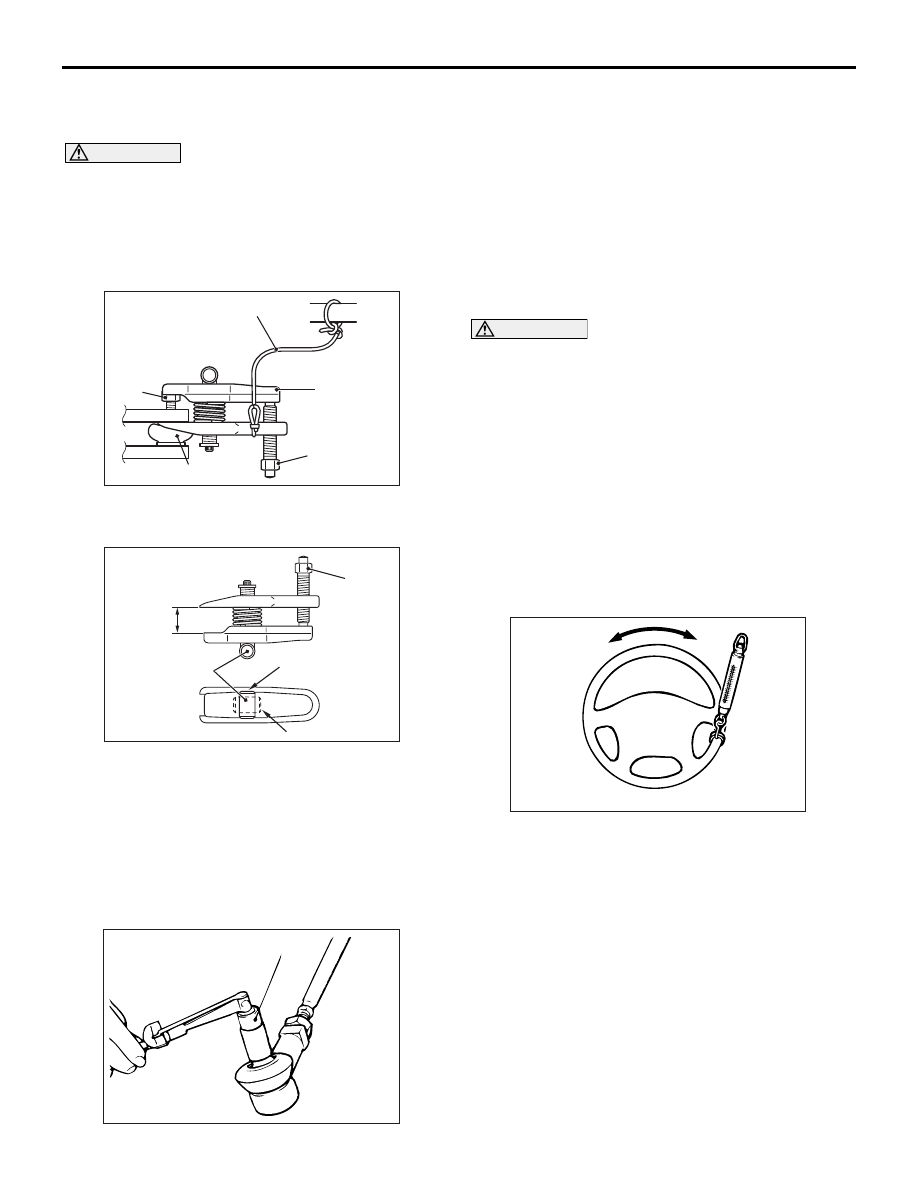

• Do not remove the tie rod end nut from the

ball joint. Loosen it and use special tool to

avoid possible damage to the ball joint

threads.

• Hang special tool with cord to prevent it from

falling.

1. Install special tool ball joint remover (MB991897)

as shown in the figure.

2. Turn the bolt and knob as necessary to make the

jaws of special tool parallel, tighten the bolt by

hand and confirm that the jaws are still parallel.

NOTE: When adjusting the jaws in parallel, make

sure the knob is in the position shown in the

figure.

3. Tighten the bolt with a wrench to disconnect the

tie rod end.

4. Move the ball joint stud several times and install

the nut on the stud. Using special tool preload

socket (MB990326), measure the ball joint turning

torque.

Standard value: 3.9 N

⋅m or less

5. If the turning torque exceeds the standard value,

replace the tie rod end. (Refer to

6. If the turning torque is under the standard value,

check the ball joint for axial play or ratcheting. If

no axial play or ratcheting, the ball joint can be

re-used. (Refer to

CAUTION

Always use a new ball joint nut as it is a

self-locking nut.

7. Install the tie rod end to the knuckle, then tighten a

new self-locking nut to the specified torque.

Tightening torque: 25

± 5 N⋅m

STATIONARY STEERING EFFORT CHECK

M1372001700451

1. With the vehicle stopped on a flat and paved

surface, turn the steering wheel to the straight

ahead position.

2. Start the engine and set the engine idle speed.

Standard value: 1000

± 100 r/min

3. Attach a spring balance to the outer

circumference of the steering wheel and measure

the steering force required to turn the steering

wheel from the straight ahead position to the left

and right (within a range of 1.5 turns). Also check

to be sure that there is no significant change in

the required steering effort.

Standard value:

Steering effort: 25 N or less

Fluctuation allowance: 6.0 N or less

4. If the measured value exceeds the standard

value, check and adjust the related parts.

AC208247AD

Cord

Bolt

MB991897

Nut

Ball joint

AC106821

Knob

Parallel

Bolt

Good

Bad

AB

ACX01129 AB

MB990326

ACX01122 AB