Mitsubishi Grandis. Manual - part 963

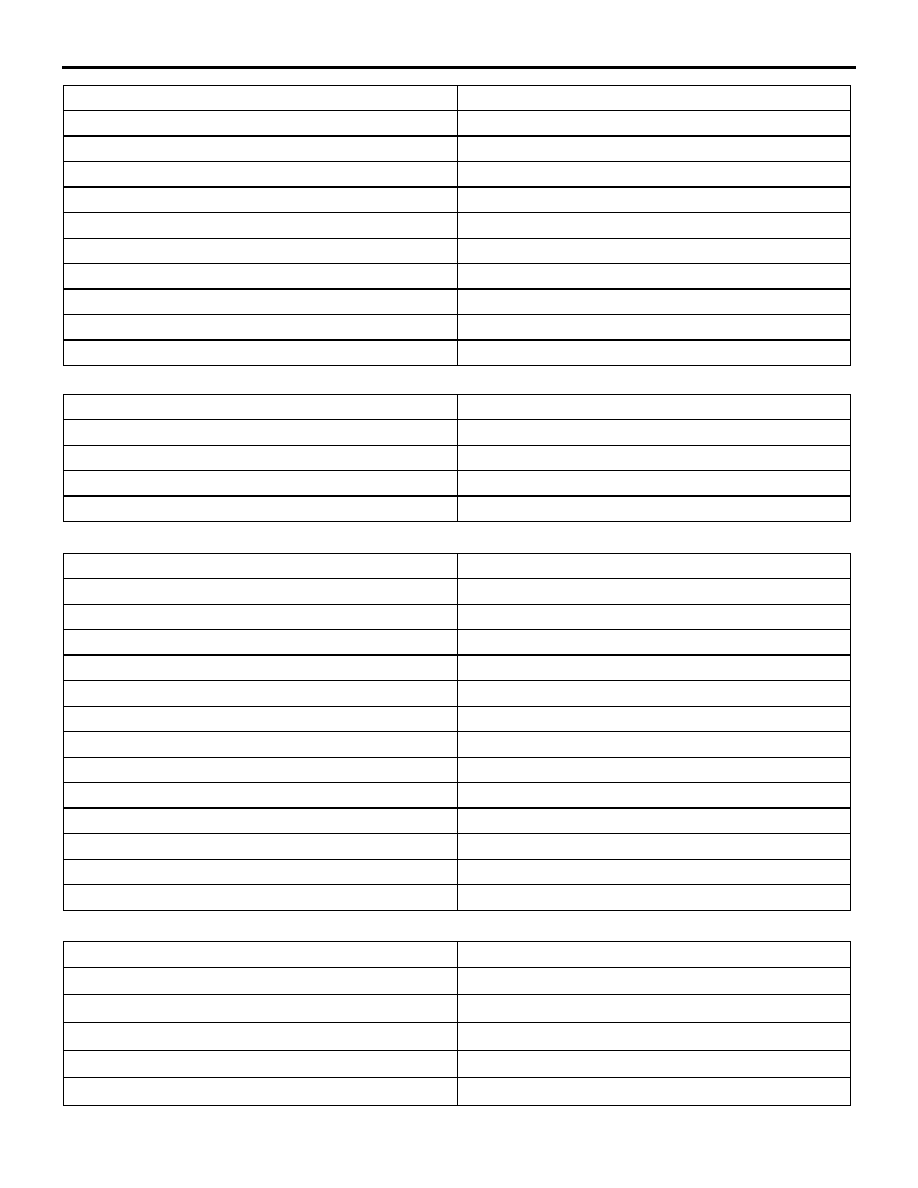

SNAP RING, SPACER, THRUST WASHER, THRUST RACE AND PRESSURE PLATE FOR

AUTOMATIC TRANSMISSION OVERHAUL

23B-8

SNAP RING (FOR ADJUSTMENT OF OVERDRIVE CLUTCH RETURN SPRING RETAINERS END PLAY)

SNAP RING (FOR ADJUSTMENT OF REVERSE CLUTCH END PLAY)

SPACER (FOR ADJUSTMENT OF BACKLASH BETWEEN DIFFERENTIAL SIDE GEARS AND PINION)

2.1

Brown

2.2

None

2.3

Blue

2.4

Brown

2.5

None

2.6

Blue

2.7

Brown

2.8

None

2.9

Blue

3.0

Brown

Thickness mm

Identification symbol

1.48

Brown

1.53

None

1.58

Blue

1.63

Brown

Thickness mm

Identification symbol

1.6

None

1.7

Blue

1.8

Brown

1.9

None

2.0

Blue

2.1

Brown

2.2

None

2.3

Blue

2.4

Brown

2.5

None

2.6

Blue

2.7

Brown

2.8

None

Thickness mm

Identification symbol

0.75

− 0.82

−

0.83

− 0.92

−

0.93

− 1.00

−

1.01

− 1.08

−

1.09

− 1.16

−

Thickness mm

Identification symbol