Mitsubishi Grandis. Manual - part 894

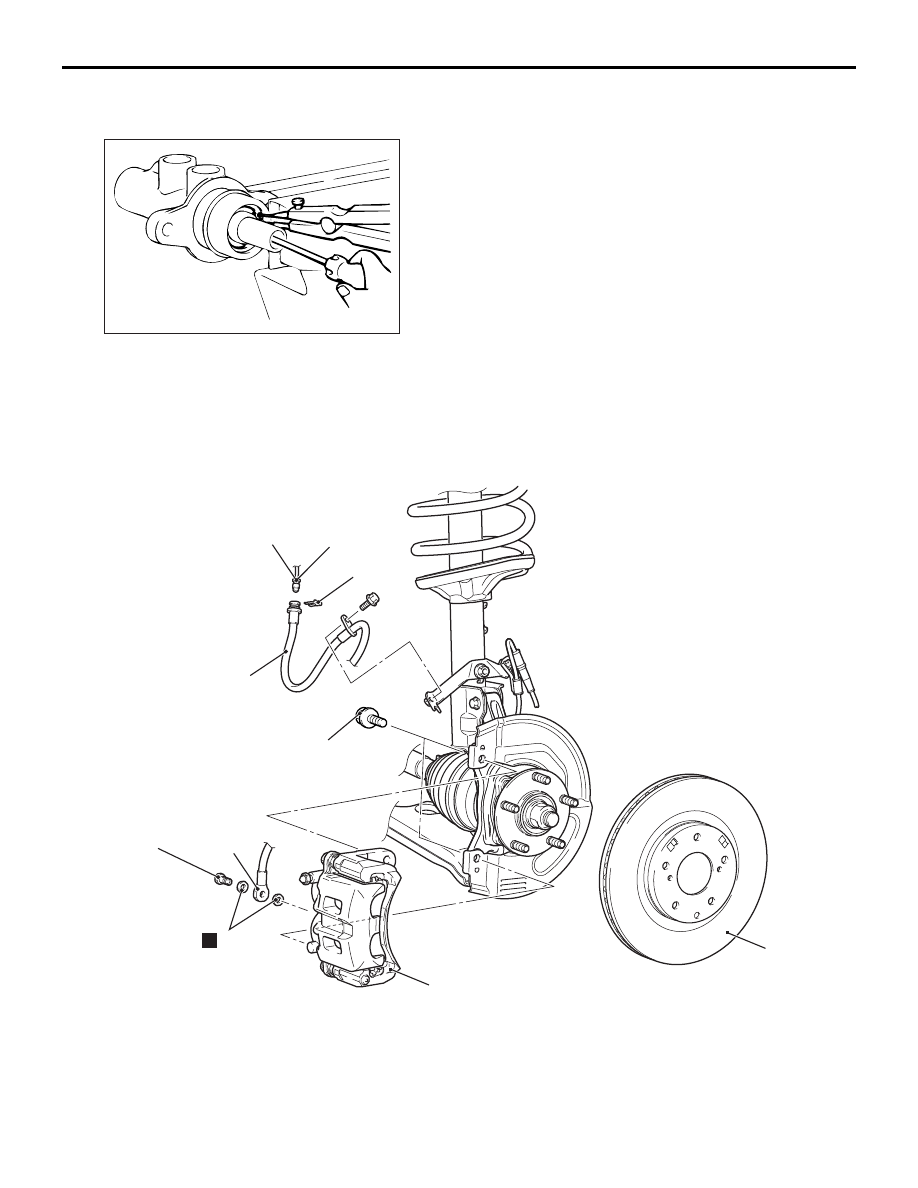

FRONT DISC BRAKE ASSEMBLY

BASIC BRAKE SYSTEM

35A-18

DISASSEMBLY SERVICE POINT

<<A>> CIRCLIP REMOVAL

While pushing the primary piston assembly, remove

the circlip.

INSPECTION

M1351004300349

• Check the inner surface of master cylinder body

for rust or pitting.

• Check the primary and secondary pistons for

rust, scoring, wear or damage.

FRONT DISC BRAKE ASSEMBLY

REMOVAL AND INSTALLATION

M1351006000537

AC104263

AC311384 AB

100 ± 10 N·m

30 ± 4 N·m

3

1

2

N

6

7

5

15 ± 2 N·m

4

Removal steps

•

Brake fluid draining

1. Brake hose connection

2. Gasket

3. Front brake assembly

<<A>>

4. Front brake disc

5. Clip

6. Brake pipe and brake hose

connection

7. Brake hose

Removal steps (Continued)