Mitsubishi Grandis. Manual - part 893

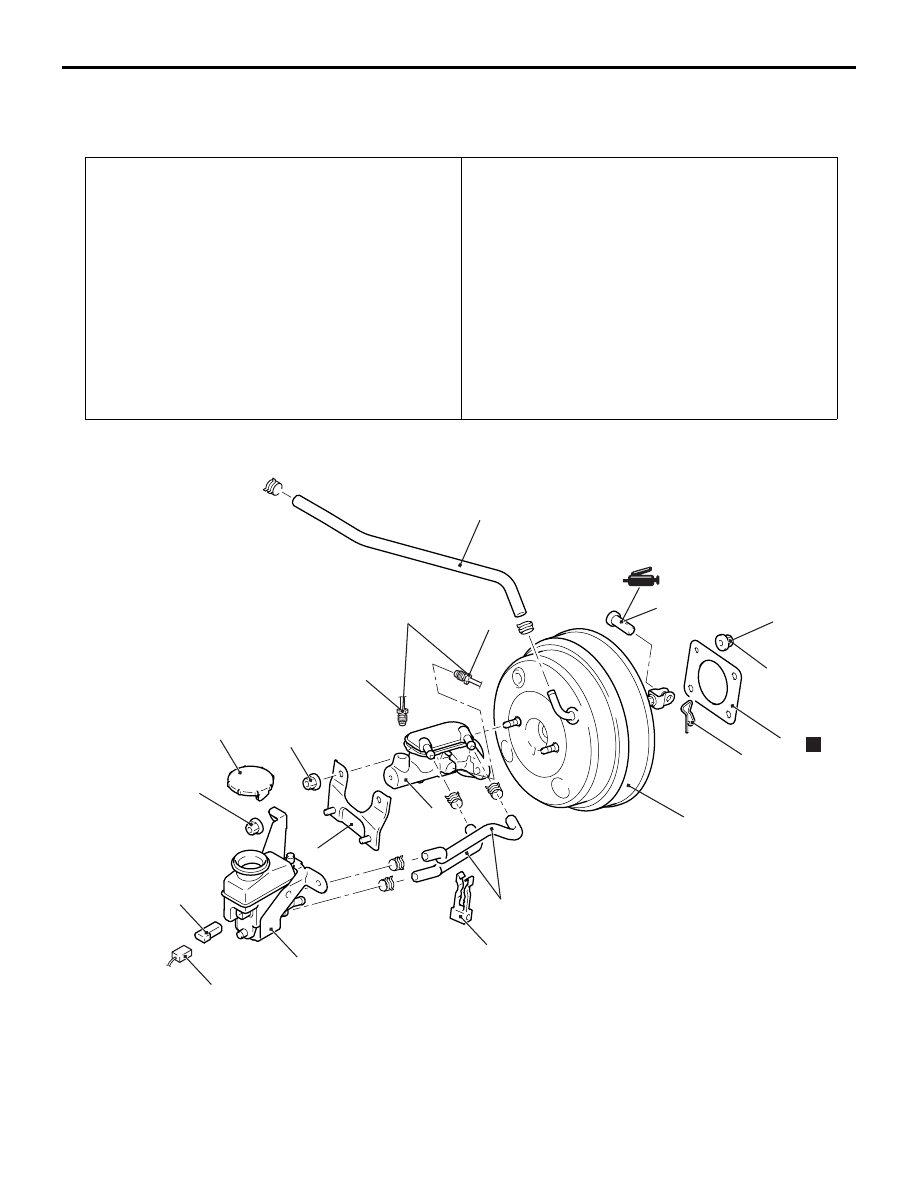

MASTER CYLINDER ASSEMBLY AND BRAKE BOOSTER

BASIC BRAKE SYSTEM

35A-14

MASTER CYLINDER ASSEMBLY AND BRAKE BOOSTER

REMOVAL AND INSTALLATION

M1351003700548

<LH drive vehicles>

Pre-removal Operation

• Air Cleaner Resonator, Air Cleaner Cover, Air Cleaner

Intake Duct, Air Cleaner Body Assembly Removal (Refer

to GROUP 15, Air Cleaner

.) <LH drive vehicles>

• Engine Cover and Engine Cover Bracket Removal (Refer

to GROUP 11A, Camshaft and Valve Stem Seal

.) <LH drive vehicles>

• Air Intake Hose Removal (Refer to GROUP 15, Air

Cleaner

.) <LH drive vehicles>

• Canister removal (Refer to GROUP 17, Evaporative

Emission Control System

− Canister

.) <LH drive

vehicles>

• Brake Fluid Draining

Post-installation Operation

• Brake Fluid Supplying and Air Bleeding (Refer to

.)

• Canister Installation (Refer to GROUP 17, Evaporative

Emission Control System

− Canister

.) <LH drive

vehicles>

• Brake Pedal Adjustment (Refer to

• Air Intake Hose Installation (Refer to GROUP 15, Air

Cleaner

.) <LH drive vehicles>

• Engine Cover and Engine Cover Bracket Installation

(Refer to GROUP 11A, Camshaft and Valve Stem Seal

.) <LH drive vehicles>

• Air Cleaner Resonator, Air Cleaner Cover, Air Cleaner

Intake Duct, Air Cleaner Body Assembly Installation

(Refer to GROUP 15, Air Cleaner

vehicles>

AC312193

AB

1

10

12

14

13

15 ± 2 N·m

14 ± 3 N·m

6

11

15

N

8

14.7 ± 2.9 N·m

2

7

5

3

4

13 ± 2 N·m

9

7

Master cylinder removal steps

1.

Brake fluid level switch connector

2.

Hose clip

>>C<<

3.

Reservoir hose

4.

Reservoir assembly

5.

Reservoir cap

6.

Brake fluid level switch

7.

Brake pipe connection

•

Brake pipe [between brake master

cylinder and hydraulic unit

(ABS-ECU)] (Refer to GROUP 35B,

Hydraulic Unit

Master cylinder removal steps