Mitsubishi Grandis. Manual - part 876

TRANSMISSION

MANUAL TRANSMISSION OVERHAUL

22B-14

3. Install the clutch housing and tighten the bolts to

the specified torque of 44

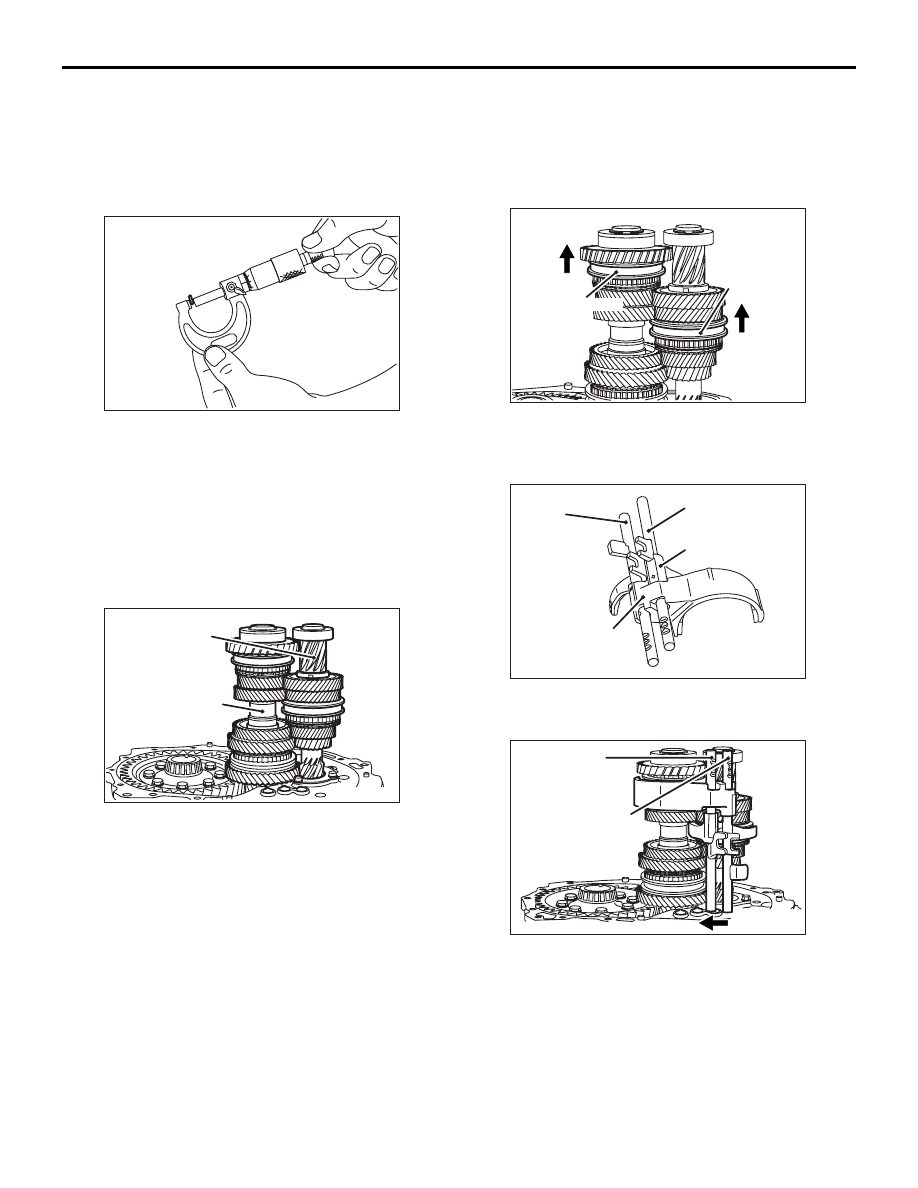

± 5 N⋅m.

4. Remove the clutch housing, and then remove the

differential assembly.

5. Remove the outer race and take out crushed

solders.

6. Measure the thickness of the crushed solder with

a micrometer and select a spacer that will provide

the standard preload value.

Standard value: 0.05

− 0.11 mm preload

REASSEMBLY SERVICE POINTS

>>A<< OUTPUT SHAFT/INPUT SHAFT

INSTALLATION

Install the input and output shafts together.

>>B<< 5TH SPEED-REVERSE SHIFT

FORK/5TH SPEED-REVERSE SHIFT

RAIL/3RD-4TH SPEED SHIFT

FORK/3RD-4TH SPEED SHIFT RAIL

INSTALLATION

1. Shift the 3rd-4th speed synchronizer sleeve and

5th speed-reverse synchronizer sleeve in the

direction shown.

2. Assemble the 3rd-4th speed shift rail and fork,

and the 5th speed-reverse shift rail and fork.

3. While fitting each shift fork in the groove of

synchronizer sleeve, slide the shift rails in the

direction shown and install.

4. Insert the 3rd-4th speed shift rail and 5th

speed-reverse shift rail into the rail hole in the

clutch housing.

>>C<< SPRING PIN INSTALLATION

1. Align the pin holes in the shift rail and shift fork.

AK305233

AK305106AB

Input shaft

Output shaft

AK305111AB

3rd-4th speed

synchronizer

sleeve

5th speed-reverse

synchronizer

sleeve

AK305112AB

3rd-4th speed

shift rail

3rd-4th speed

shift fork

5th speed-reverse

shift fork

5th speed-reverse

shift rail

AK305104AC

3rd-4th speed

shift rail

5th speed-reverse

shift rail