Mitsubishi Grandis. Manual - part 872

CLUTCH

CLUTCH OVERHAUL

21B-4

REMOVAL SERVICE POINT

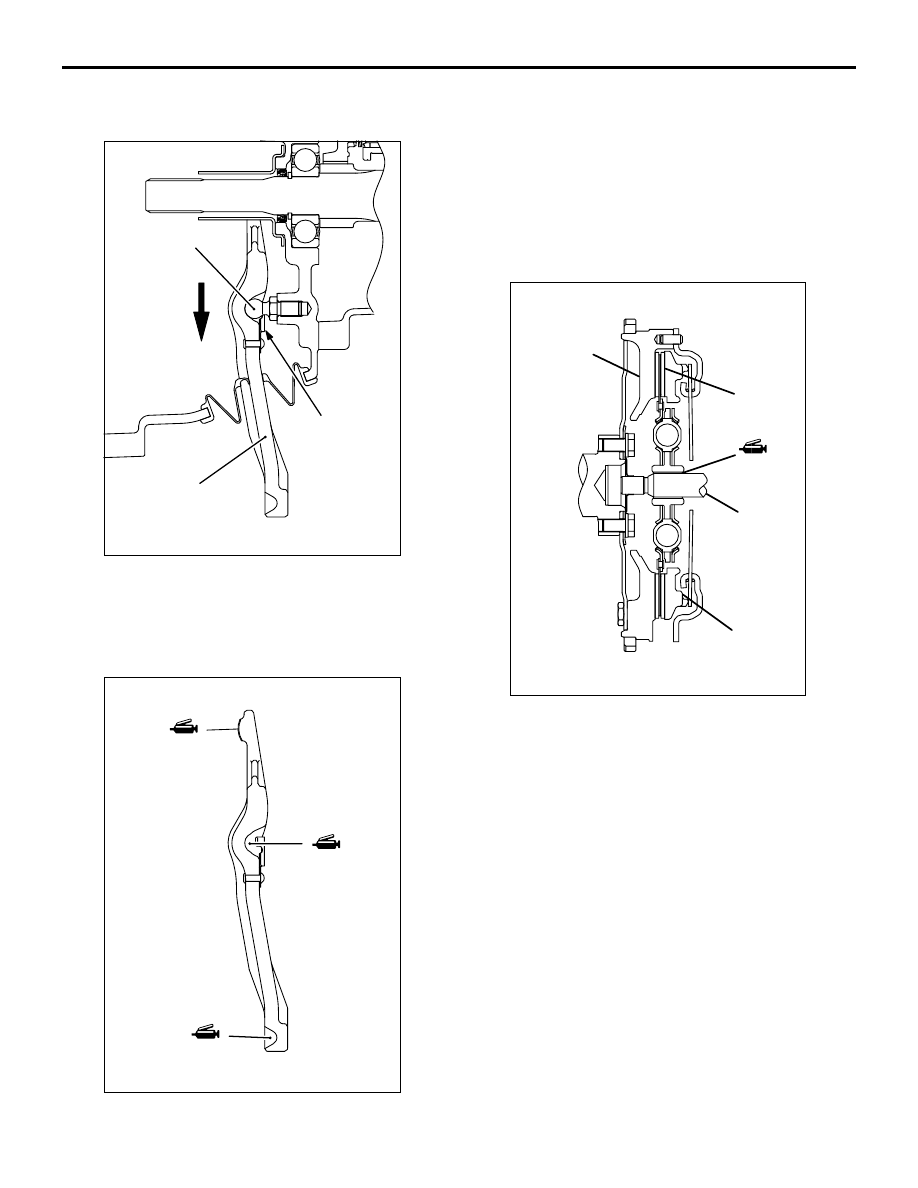

<<A>> RELEASE FORK REMOVAL

Move the release fork in the direction shown to

remove the clip from the fulcrum.

INSTALLATION SERVICE POINTS

>>A<< RELEASE FORK INSTALLATION

1. Apply grease to the illustrated positions of the

release fork.

Specified grease:

Mitsubishi genuine grease Part No.0101011 or

equivalent

2. Install the release fork to the fulcrum.

>>B<< CLUTCH DISC AND CLUTCH

COVER INSTALLATION

1. Apply grease to the clutch disc splines and rub it

in the splines with a brush.

Specified grease:

Mitsubishi genuine grease Part No.0101011 or

equivalent

2. Using the clutch disc guide to position the clutch

disc on the flywheel.

3. Install the clutch cover onto the flywheel.

INSPECTION

M1212001100166

CLUTCH COVER

1. Check the diaphragm spring end for wear and

uneven height. Replace if wear is evident or

height difference exceeds the limit.

Limit: 0.5 mm

2. Check the pressure plate surface for wear, cracks

and discoloration.

3. Check the rivets of the strap plate for looseness. If

loose, replace the clutch cover.

AK204409

Fulcrum

Clip

Release fork

AB

AK204410

Apply grease

Apply grease

Apply grease

AB

AK204214

Flywheel

Clutch disc

Clutch disc

guide

Clutch cover

AB