Mitsubishi Grandis. Manual - part 647

CHARGING SYSTEM

ENGINE ELECTRICAL

16-12

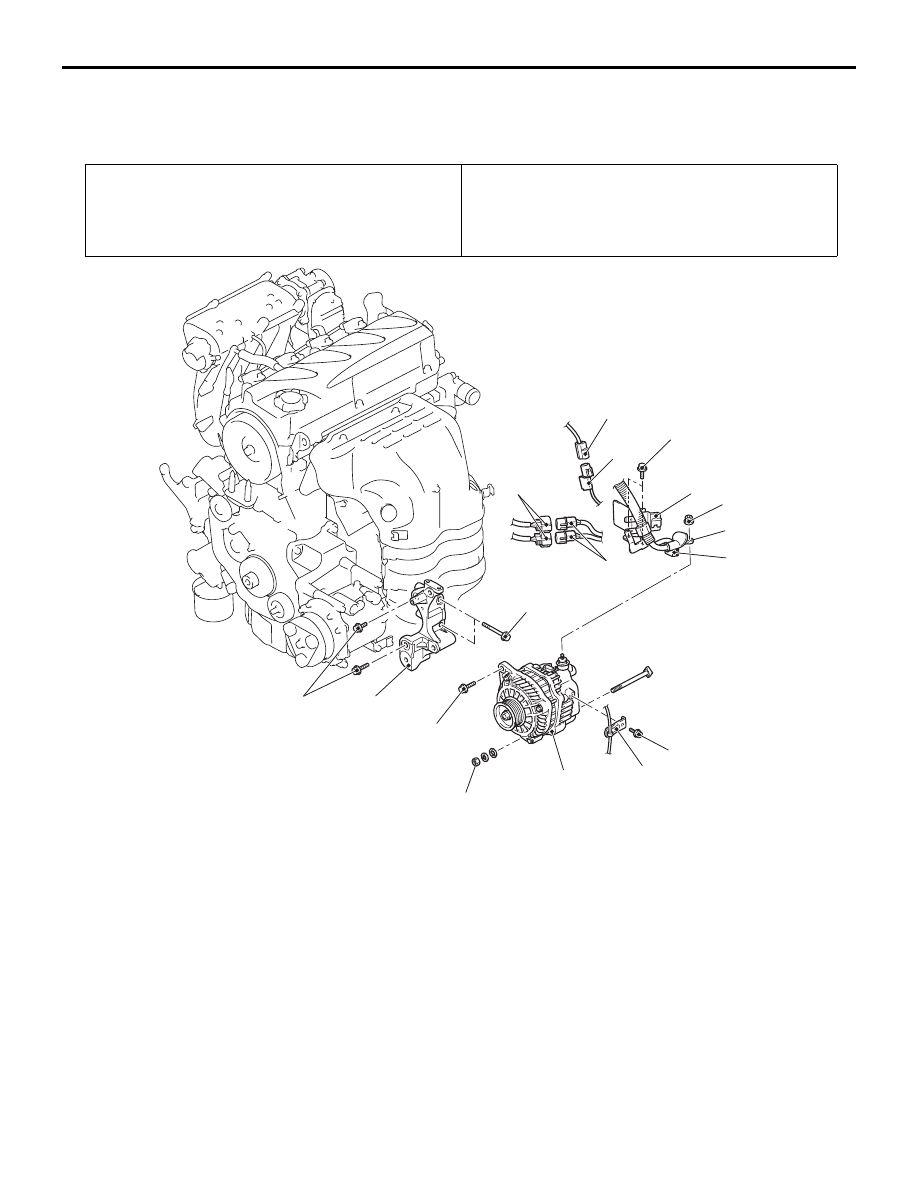

ALTERNATOR ASSEMBLY

REMOVAL AND INSTALLATION

M1161001400742

REMOVAL SERVICE POINT

<<A>> ALTERNATOR ASSEMBLY

REMOVAL

Remove the alternator assembly from above the

vehicle.

Pre-removal Operation

Drive Belt Removal (Refer to GROUP 11A, Crankshaft

Pulley

).

Post-installation Operation

• Drive Belt Installation (Refer to GROUP 11A, Crankshaft

Pulley

).

• Drive Belt Tension Check (Refer to GROUP 11A,

On-vehicle Service

).

AC313042

11 ± 1 N·m

11 ± 1 N·m

14 ± 3 N·m

1

6

5

3

7

4

9

8

10

AB

44 ± 10 N·m

49 ± 9 N·m

49 ± 9 N·m

2

49 ± 9 N·m

Removal steps

1.

Oxygen sensor connector

2.

Oxygen sensor connector clamp

3.

A/C compressor assembly

connector

4.

A/C compressor assembly

connector clamp

5.

Alternator connector

6.

Alternator terminal

7.

Connector bracket

8.

Harness clamp

<<A>>

9.

Alternator assembly

•

Timing belt lower cover (Refer to

GROUP 11A, Timing Belt

10. Alternator mounting bracket

Removal steps (Continued)