Mitsubishi Grandis. Manual - part 645

CHARGING SYSTEM

ENGINE ELECTRICAL

16-4

SPECIAL TOOLS

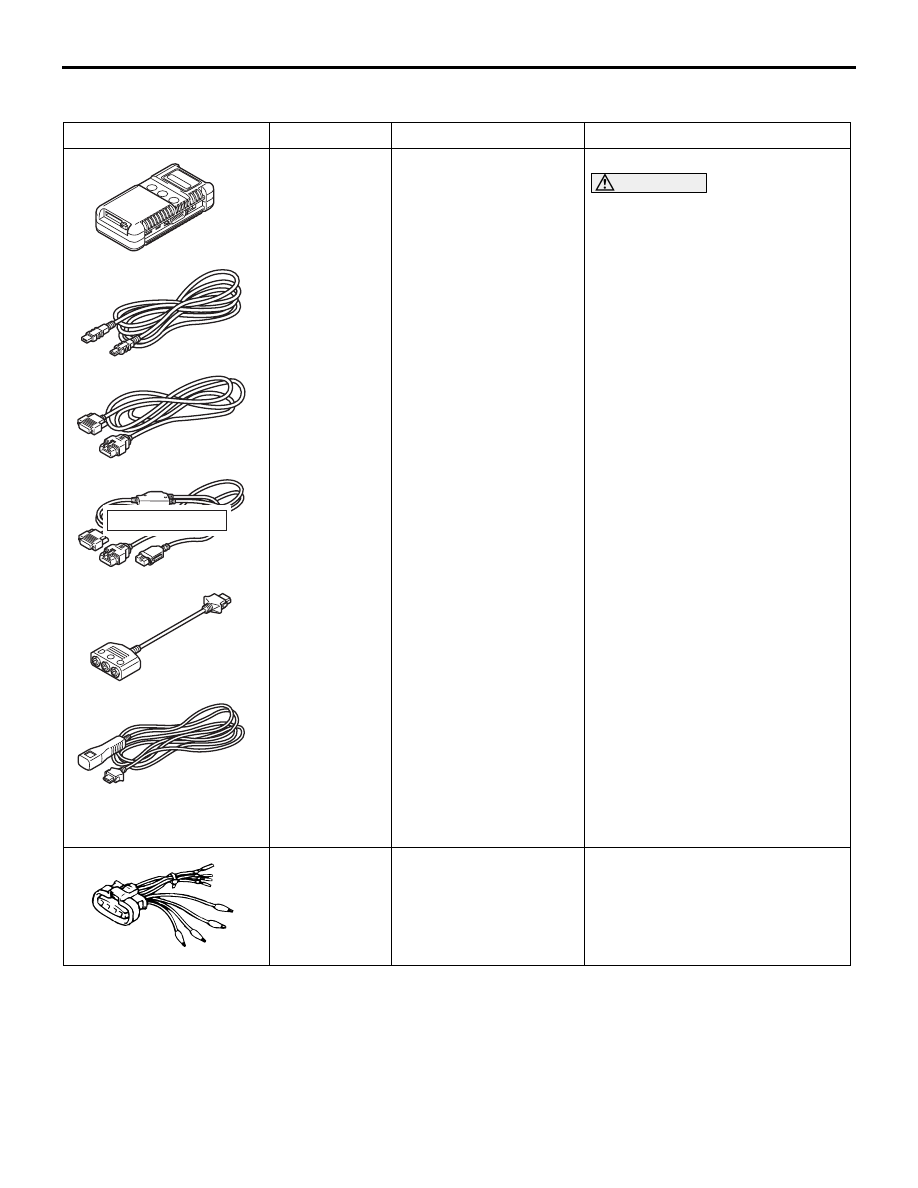

M1161000600367

Tool

Number

Name

Use

MB991955

A: MB991824

B: MB991827

C: MB991910

D: MB991911

E: MB991825

F: MB991826

MUT-III sub assembly

A: Vehicle

communication

interface (V.C.I.)

B: MUT-III USB cable

C: MUT-III main harness

A (Vehicles with CAN

communication

system)

D: MUT-III main harness

B (Vehicles without

CAN communication

system)

E: MUT-III measurement

adapter

F: MUT-III trigger

harness

Checking the idle speed

CAUTION

For vehicles with CAN

communication, use MUT-III

main harness A to send

simulated vehicle speed. If you

connect MUT-III main harness B

instead, the CAN

communication does not

function correctly.

MB991519

Alternator test harness

Checking the alternator

("S" terminal voltage)

MB991910

MB991826

MB991955

MB991911

MB991824

MB991827

MB991825

A

B

C

D

E

F

DO NOT USED