Mitsubishi Grandis. Manual - part 642

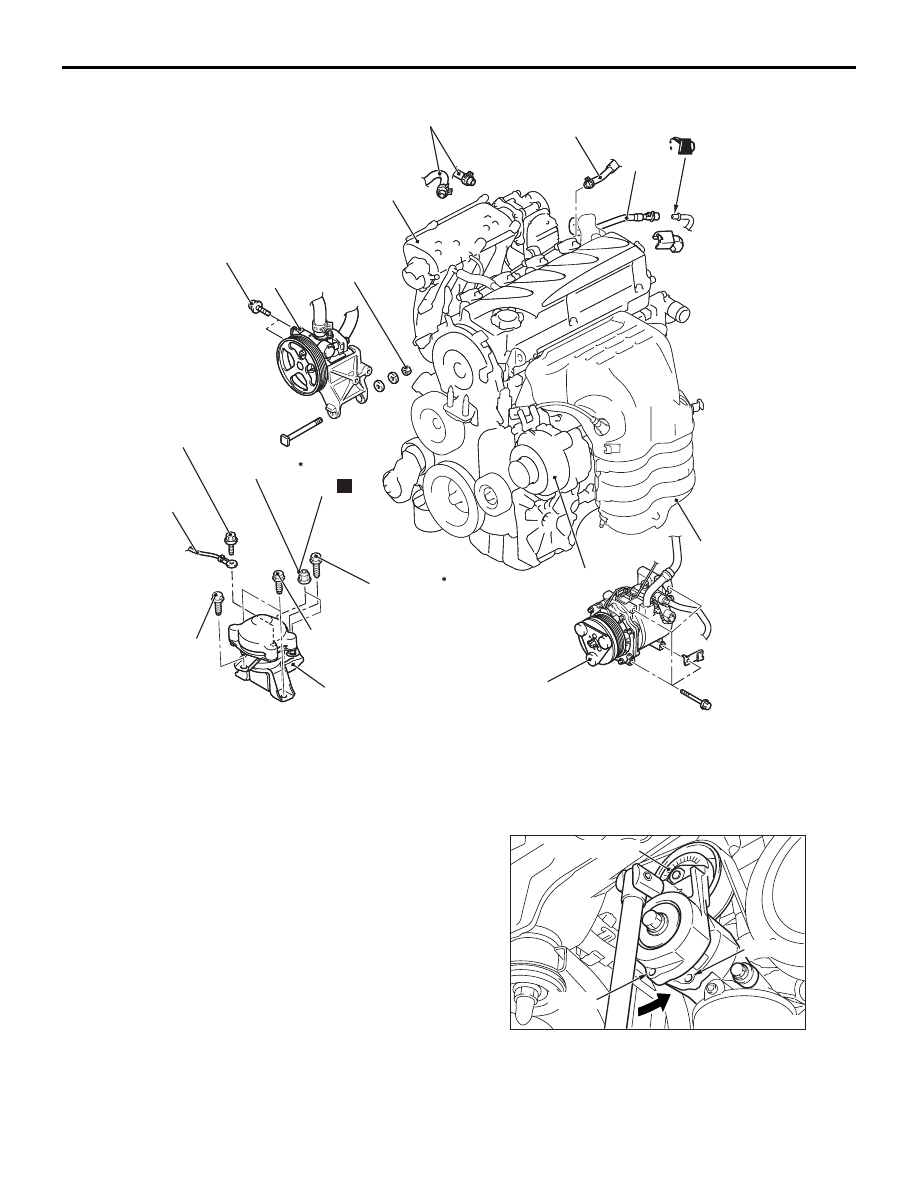

ENGINE ASSEMBLY

ENGINE MECHANICAL

11A-45

REMOVAL SERVICE POINTS

<<A>> DRIVE BELT REMOVAL

The following operations will be needed due to the

introduction of the serpentine drive system with the

drive belt auto-tensioner.

1. Securely insert the spindle handle or ratchet

handle with a 12.7 mm insertion angle into the jig

hole of the auto-tensioner.

2. Rotate the auto-tensioner anti-clockwise and align

hole A with hole B.

AC312969AB

AC312969

18

17

16

15

14

13

12

11

10

9

N

8

78 ± 7 N·m

78 ± 7 N·m

78 ± 7 N·m

(Engine oil)

5.0 ± 1.0 N·m

24 ± 4 N·m

44 ± 10 N·m

78 ± 7 N·m

Removal steps

<<B>>

8.

Power steering oil pump and

bracket assembly

<<C>>

9.

A/C compressor and clutch

assembly

10. Exhaust manifold (Refer to GROUP

15, Exhaust Manifold

11. Alternator assembly (Refer to

GROUP 16, Charging System,

Alternator Assembly

12. Heater water hoses connection

13. Fuel return line hose connection

<<D>>

>>E<<

14. Fuel high-pressure hose

connection

<<E>>

>>D<<

•

Transmission assembly

>>C<<

•

Radiator assembly

15. Earth cable connection

16. Self-locking nuts

<<G>>

>>B<<

17. Engine front mounting bracket

<<H>>

>>A<<

18. Engine assembly

AC301703

AC301704AB

Hole A

Auto-tensioner

Hole B