Mitsubishi Grandis. Manual - part 641

TIMING BELT

ENGINE MECHANICAL

11A-41

CAUTION

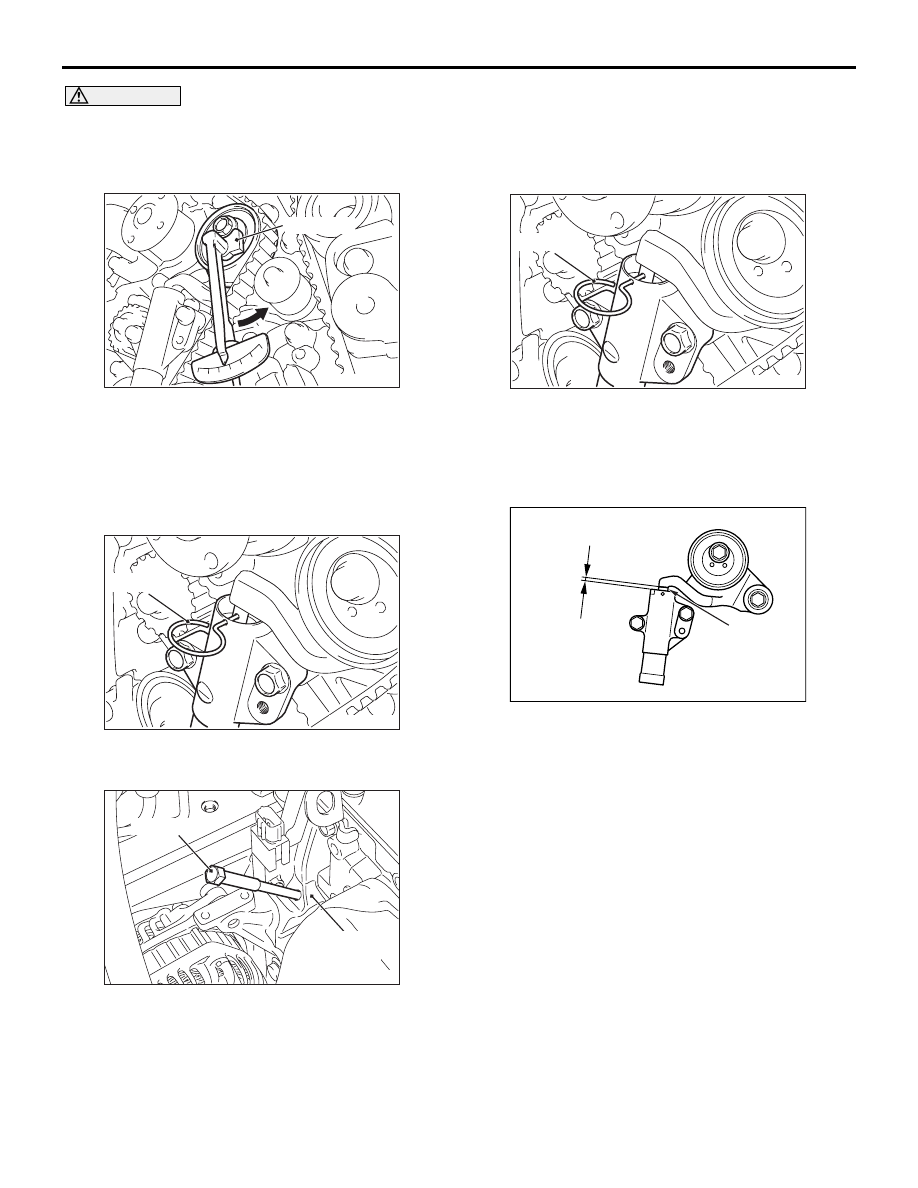

When tightening the mounting bolt, ensure that

the timing belt tensioner pulley does not rotate

with the bolt. Allowing it to rotate with the bolt

can cause deficient tension of the belt.

6. With special tool tensioner wrench (MD998767)

and torque wrench, apply tension torque 3.5 N

⋅m

to the valve timing belt, and tighten the timing belt

tensioner pulley mounting bolt to the specified

torque.

Tightening torque: 48

± 5 N⋅m

7. Remove wire or pin inserted to timing belt

tensioner adjuster.

8. Remove special tool adjusting bolt (MD998738),

and install the rubber plug to the timing belt under

cover.

9. Rotate crankshaft clockwise two turns, and leave

it for about 15 minutes.

10.Insert wire or pin removed in Step 7 again, and

ensure that it can be pulled out with a light load.

When wire or pin can be lightly removed,

appropriate tension is applied on timing belt. In

this case, remove wire or pin.

Also the projection of timing belt tensioner

adjuster rod (A) is within the standard value,

appropriate tension is applied.

Standard value (A): 3.8

− 4.5 mm

11.If wire or pin cannot be easily pulled out, repeat

Step 1 through Step 9 to reach proper valve timing

belt tension.

AC301859

MD998767

AB

AC301857AB

Wire or pin

AC301452AB

MD998738

Timing belt

under cover

AC301857AB

Wire or pin

AC301375

AB

A

Rod