Mitsubishi Grandis. Manual - part 333

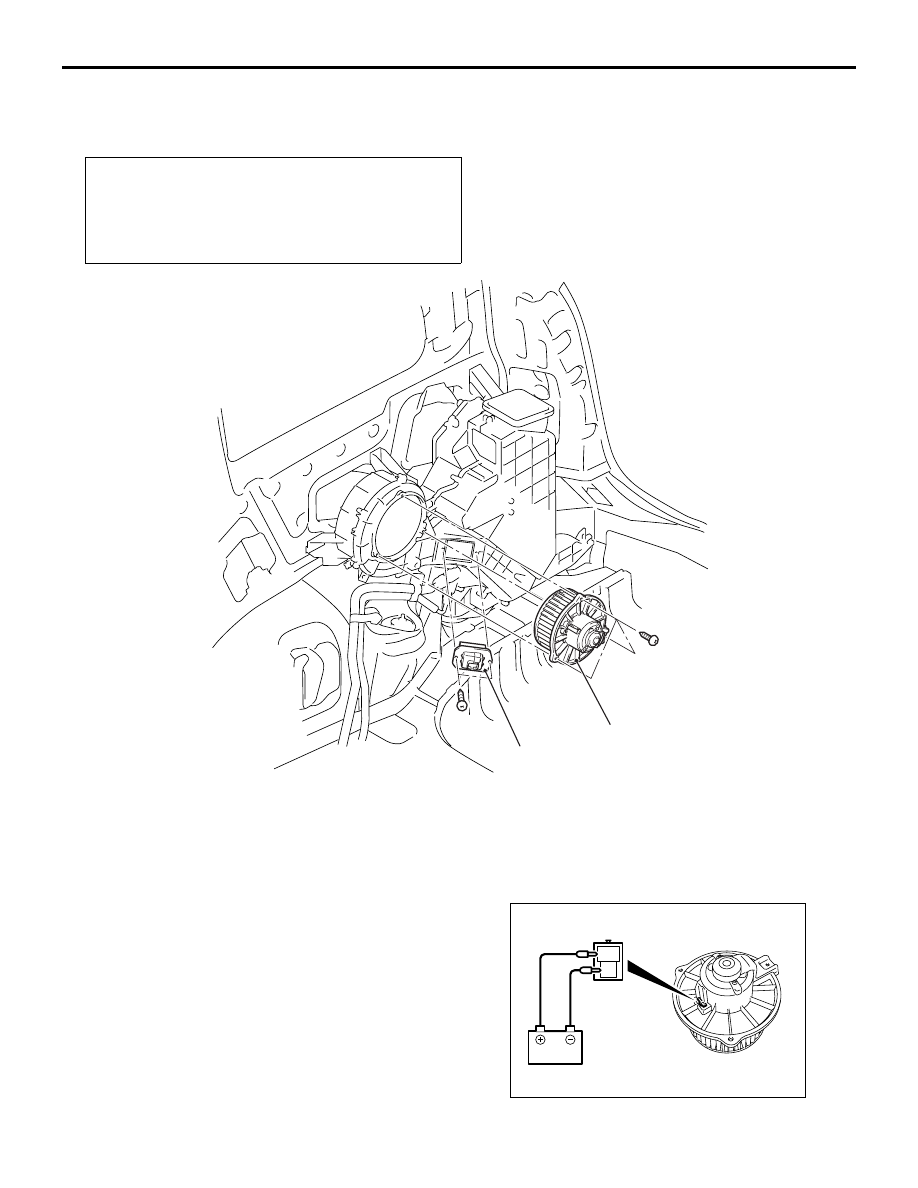

REAR BLOWER MOTOR AND REAR POWER TRANSISTOR

HEATER, AIR CONDITIONER AND VENTILATION

55-217

REAR BLOWER MOTOR AND REAR POWER TRANSISTOR

REMOVAL AND INSTALLATION

M1554015500027

INSPECTION

M1554011900045

REAR BLOWER MOTOR INSPECTION

<VEHICLES WITH REAR HEATER, REAR

COOLER OR DUAL AUTOMATIC A/C>

Pre-removal and Post-installation Operation

• Third seat assembly Removal and Installation (Refer to

GROUP 52A, Third Seat Assembly

.)

• Quarter trim lower, quarter trim upper Removal and

Installation (Refer to GROUP 52A, Interior Trim

AC302929

1

2

AC

Rear power transistor removal

step

1.

Rear power transistor <Vehicles

with rear heater, rear cooler or dual

automatic A/C>

Rear blower motor removal

steps

•

Rear floor duct A <Vehicles with

rear heater or rear A/C> (Refer to

2.

Rear blower motor <Vehicles with

rear heater, rear cooler or dual

automatic A/C>

AC303108

2

1