Mitsubishi L200. Manual - part 470

AC309090

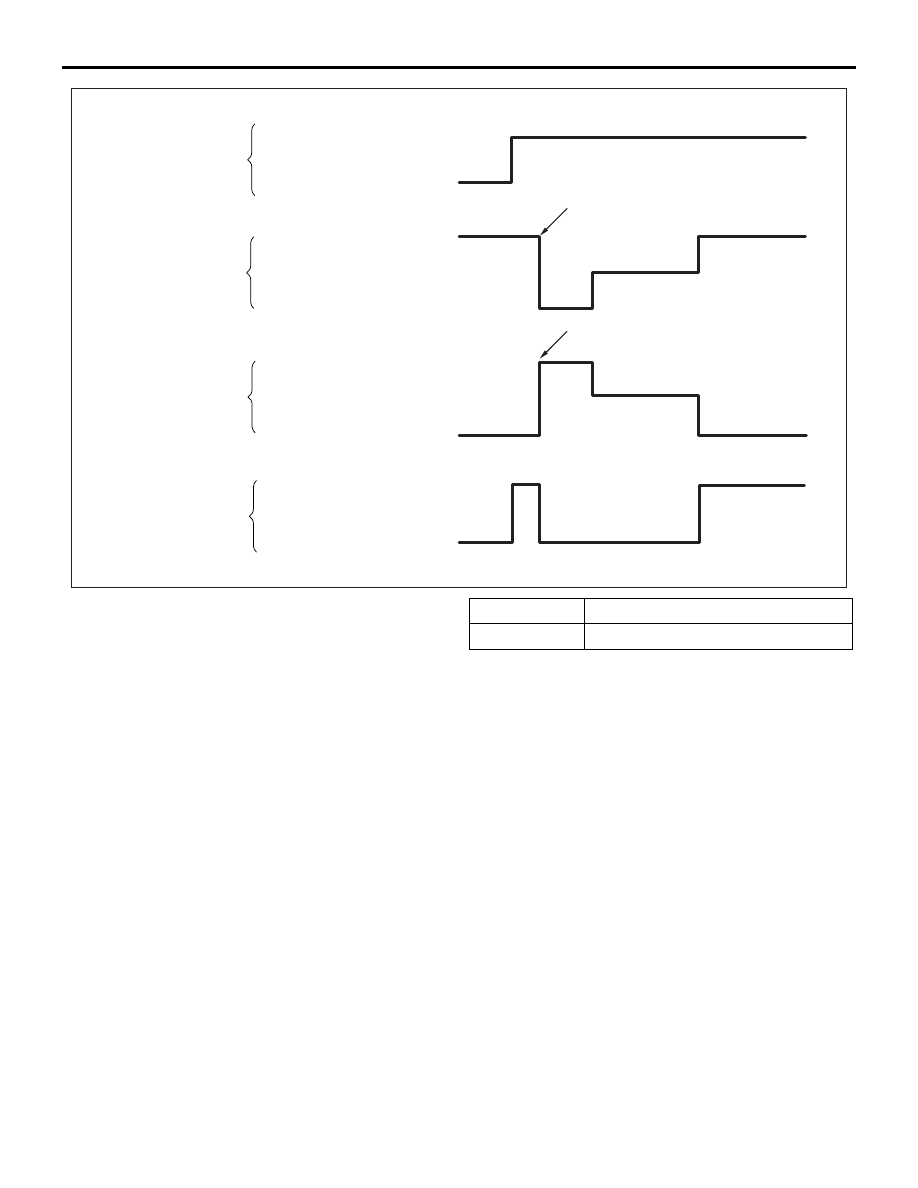

Depressed

Released

Pressure increase

Pressure decrease

Pressure hold

Lock

Drag force when the

pedal is free

Pedal operation

Solenoid valve

operation (ABS)

Solenoid valve

operation (ASC, ATC)

Checking the brake force

AD

M.U.T.-III actuator test

(Item No.01, 02, 03, 04) start

1 s

2 s

3 s

M.U.T.-III actuator test

(Item No.05, 06, 07, 08) start

2 s

1 s

Pressure increase

Pressure decrease

Pressure hold

ON-VEHICLE SERVICE

ACTIVE STABILITY & TRACTION CONTROL SYSTEM (ASTC)

35C-136

10.Turn the wheel by hand and check the change in

braking force when the brake pedal is depressed.

When using the braking force tester, depress the

brake pedal until the braking force is at the

following values, and check that the braking force

changes to the brake drag force reading taken in

step 2 when the actuator is force-driven. The

result should be as shown in the diagram above.

Front wheel

785

− 981 N

Rear wheel

588

− 784 N

11.If the result of inspection is abnormal, repair

according to the Diagnosis Table below.