Mitsubishi L200. Manual - part 402

SPECIAL TOOLS

FRONT SUSPENSION

33-4

SPECIAL TOOLS

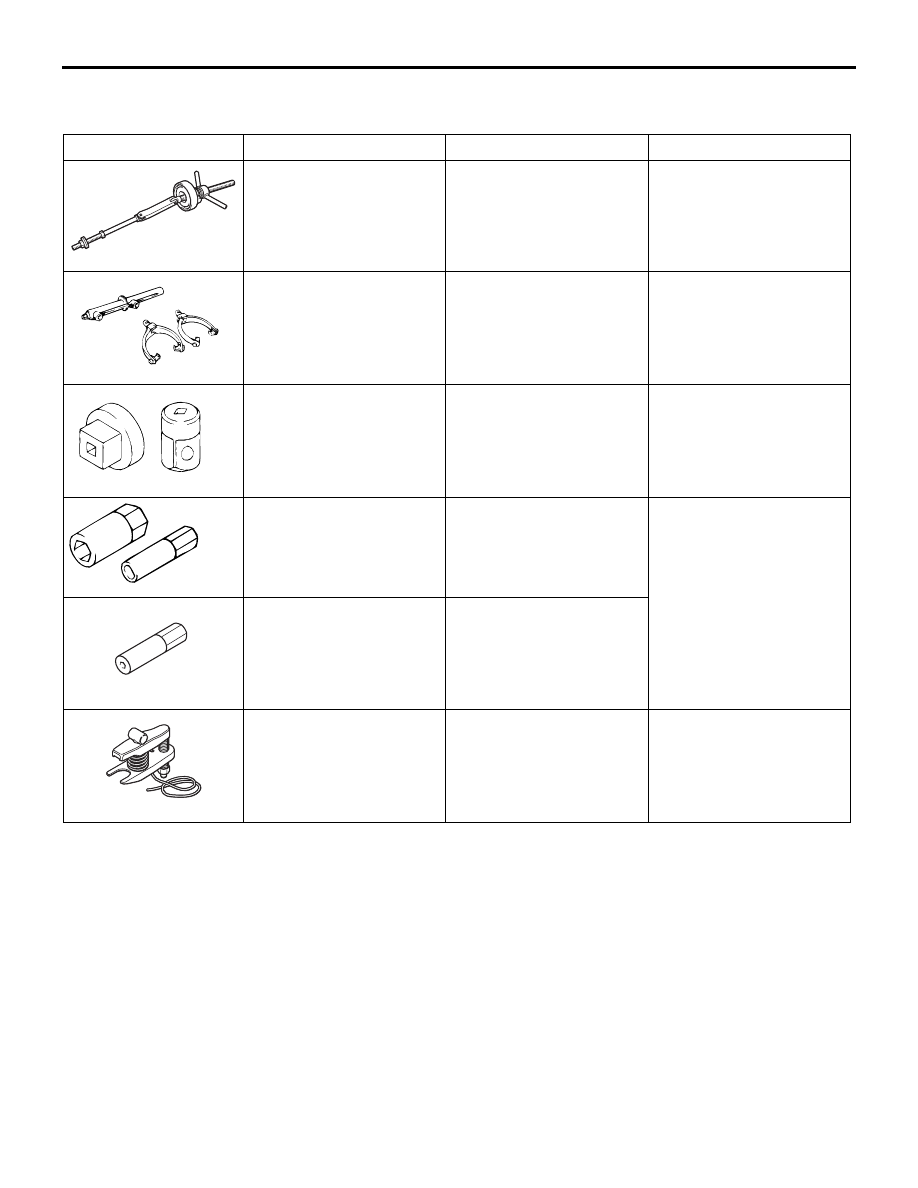

M1332000601063

Tool

Number

Name

Use

MB991783

MB992058

Coil spring compressor

Compression of front

suspension coil spring

<2WD (except High

rider)>

MB991237

A

B

A: MB991237

B: MB991238

A: Spring compressor

body

B: Arm set, large

Compression of front

suspension coil spring

<2WD (High rider), 4WD>

MB990326

MB990326

Preload socket

Ball joint starting torque

check

MB991680

A

B

MB991680

A: MB991681

Wrench and socket set

A: Wrench

Shock absorber assembly

disassembly and

reassembly

MB992047

MB992047

Socket

MB992011

MB992011

Ball joint remover

Upper arm and lower arm

ball joint disconnection