Mitsubishi L200. Manual - part 342

TRANSFER

AUTOMATIC TRANSMISSION OVERHAUL <V4A5>

23C-77

>>W<< SPRING INSTALLATION

AK403513

Install the spring with its tapered end toward the ball.

>>X<< PLUG INSTALLATION

CAUTION

• Completely degrease the FIPG-applied sur-

face so that water and oil including the old

sealant cannot adhere to the surface coated

with the sealant. Never touch the degreased

surface by hand.

•

AK403514AB

Make sure the starting point and the ending

point are about the middle between the bolts.

Apply the sealant to the threads.

Specified sealant:

3M

™ ATD Part No. 8672 or equivalent

NOTE: The new plug is percolated with sealant, so

sealant does not need to be applied.

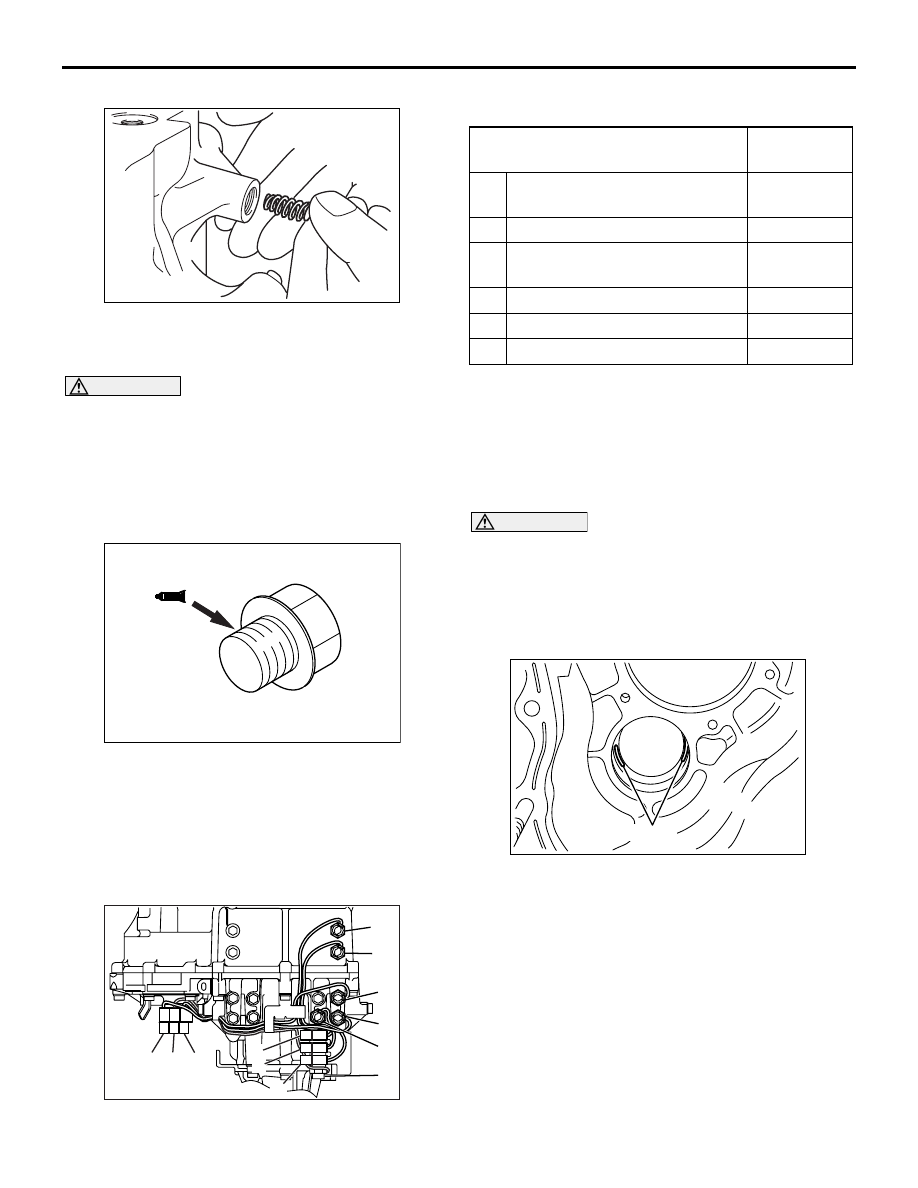

>>Y<< DETECTION SWITCH INSTALLATION

AK503496

A

B

C

D

E

F

AB

4

6

3

5

1

2

Install with care. Do not make mistake when locating

each switch.

Detection switch name

Connector

No. / Color

A

Center differential lock

detection switch

1 / Brown

B

2WD/4WD detection switch

2 / Black

C

Center differential lock

operation detection switch

4 / Blown

D

4WD operation detection switch 6 / Black

E

High/low detection switch

3 / white

F

4LLc detection switch

5 / White

ADJUSTMENT OF TRANSFER

M1233030900060

SPACER SELECTION FOR ADJUST-

MENT OF COUNTERSHAFT GEAR END

PLAY

<Measurement using a solder>

CAUTION

• If soft solder is not available, select the

spacer in accordance with Plastigage method.

• If the spacer appropriate for the standard

value cannot be selected using soft solder,

select the spacer in accordance with Plasti-

gage method.

AK403499AB

Solder

1. Put solders (1.0 mm diameter, about 10 mm long)

in the illustrated positions of the transfer case

housing.

2. Install the countershaft gear into the transfer case.

3. Install the transfer case plate and tighten the bolts

to the specified torque of 35

± 6 N⋅m.

4. Remove the transfer case plate and the

countershaft gear, and then take out crushed

solders.

5. If the solders have not crushed, use thicker

solders (1.6 mm diameter, about 10 mm long) and

repeat steps 2 to 4.