Mitsubishi L200. Manual - part 222

GLOW SYSTEM

ENGINE ELECTRICAL

16-18

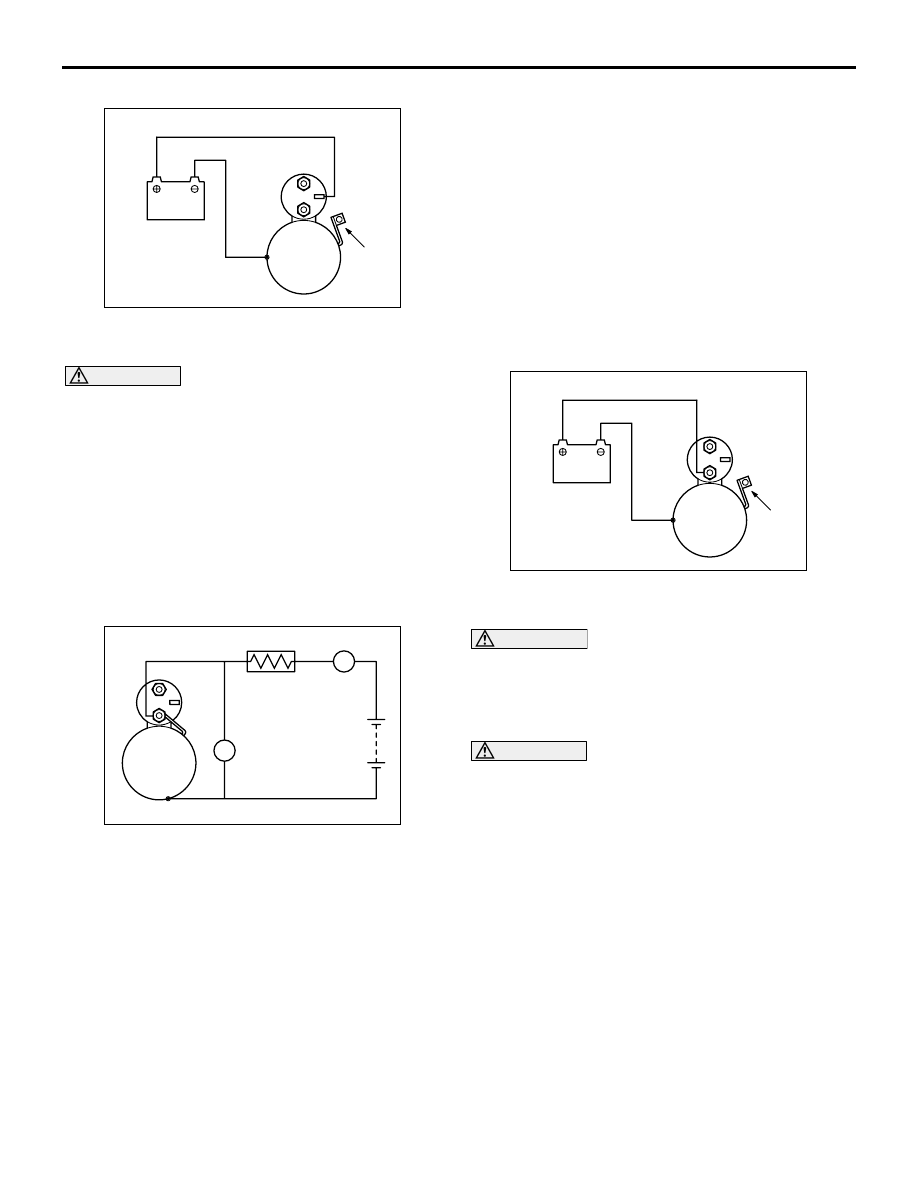

MAGNETIC SWITCH HOLD-IN TEST

AK403869

B

M

S

Battery

Starter

motor

Wire

AB

1. Disconnect the field coil wire from the M-terminal

of the magnetic switch.

CAUTION

This test must be performed quickly (in less than

10 seconds) to prevent the coil from burning.

2. Connect a 12-volt battery between the S-terminal

and body.

3. Manually pull out the pinion as far as the pinion

stopper position.

4. If the pinion remains out, everything is in order. If

the pinion moves in, the hold-in circuit is open.

Replace the magnetic switch.

FREE RUNNING TEST

AK403870

B

M

S

A

V

Ammeter

Carbon-pile

rheostat

Battery

Starter

motor

Voltmeter

AB

1. Connect a test ammeter (150-ampere scale or

more) and carbon pile rheostat in series between

the positive battery terminal and starter motor

terminal.

2. Connect a voltmeter (15-volt scale) across the

starter motor.

3. Rotate the rheostat to full-resistance position.

4. Connect the battery cable from the negative

battery terminal to the starter motor body.

5. Adjust the rheostat until the battery positive

voltage shown on the voltmeter is 11 V.

6. Confirm that the maximum amperage is within the

specifications and that the starter motor turns

smoothly and freely.

Current: Maximum 130 A

MAGNETIC SWITCH RETURN TEST

AK403871

B

S

M

Battery

Starter

motor

Wire

AB

1. Disconnect the field coil wire from the M-terminal

of the magnetic switch.

CAUTION

This test must be performed quickly (in less than

10 seconds) to prevent the coil from burning.

2. Connect a 12-volt battery between the M-terminal

and body.

WARNING

Be careful not to get your fingers caught

when pulling out the pinion.

3. Pull the pinion out and release. If the pinion

quickly returns to its original position, everything is

operating properly. If it doesn't, replace the

magnetic switch.

GLOW SYSTEM

GENERAL INFORMATION

M1164000100178

GLOW SYSTEM <EURO5>

GLOW CONTROL

The glow control unit of the glow system employs the

method of energizing the glow plug of each cylinder

respectively.

The glow control unit carries out the duty control to

the energization of the glow plug, in accordance with

the signal from the engine-ECU.This achieves the

optimum voltage of the glow plug in accordance with

the engine conditions at the after glow to stabilize the

combustion. Also the combustion noise or hydrocar-

bon (HC) emissions are reduced.