Mitsubishi L200. Manual - part 110

TROUBLESHOOTING

DIESEL FUEL

13A-236

YES :

Go to Step 7 .

NO :

Repair the damaged harness wire.

STEP 7. M.U.T.-III data list

• Refer to Data List Reference Table

a. Item 118: No. 2 exhaust gas temperature sensor

(catalyst temperature)

Q: Is the check result normal?

YES :

Intermittent malfunction (Refer to GROUP

00

− How to Use Troubleshooting/

Inspection Service Points

− How to Cope

with Intermittent Malfunctions ).

NO :

Replace the engine-ECU. When the engine-

ECU is replaced, write the chassis number

(Refer to GROUP 00

− Precautions Before

Service

− How to Perform Chassis Number

Writing ). After replacing the engine-ECU,

register the injector identification code and

learn fuel injection (Refer to GROUP 00

−

Precautions Before Service

− What The

Common Rail Engine Learns ). After

registering the injector identification code,

carry out the forcible DPF regeneration.

(Refer to GROUP 17

− Emission Control −

Diesel Particulate Filter (DPF) System

−

Forcible DPF Regeneration ).

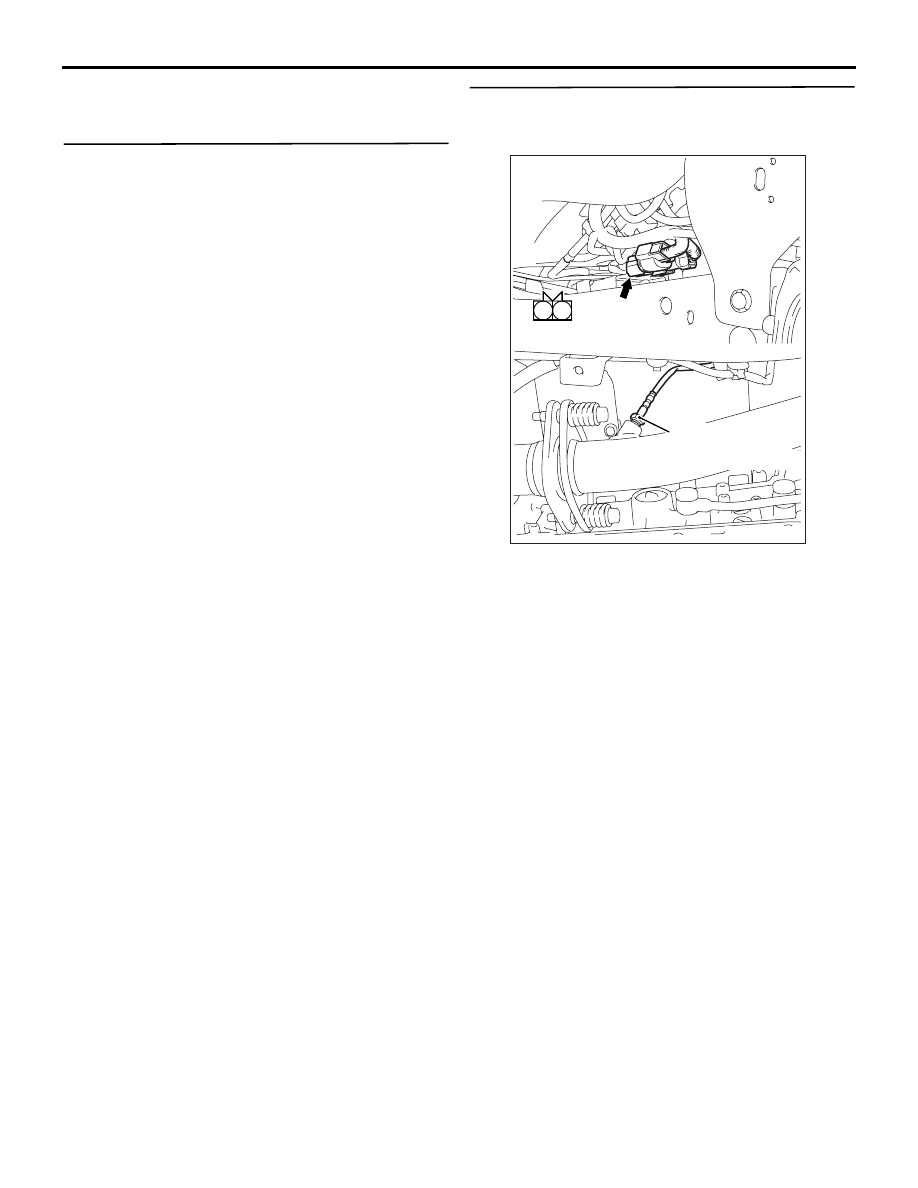

STEP 8. Perform resistance measurement at A-

159 No. 2 exhaust gas temperature sensor

(catalyst temperature) connector.

• Disconnect connector, and measure at harness

side.

• Resistance between terminal No. 2 and earth.

OK: Continuity (2

Ω or less)

Q: Is the check result normal?

YES :

Go to Step 11 .

NO :

Go to Step 9 .

1

2

AKB00272

A-159 (B)

Harness side

connector

Connector: A-159

No. 2 exhaust gas

temperature sensor

(catalyst temperature)

AB