Mitsubishi L200. Manual - part 49

LUBRICANT

ENGINE LUBRICATION

12-3

LUBRICANT

M1121000402923

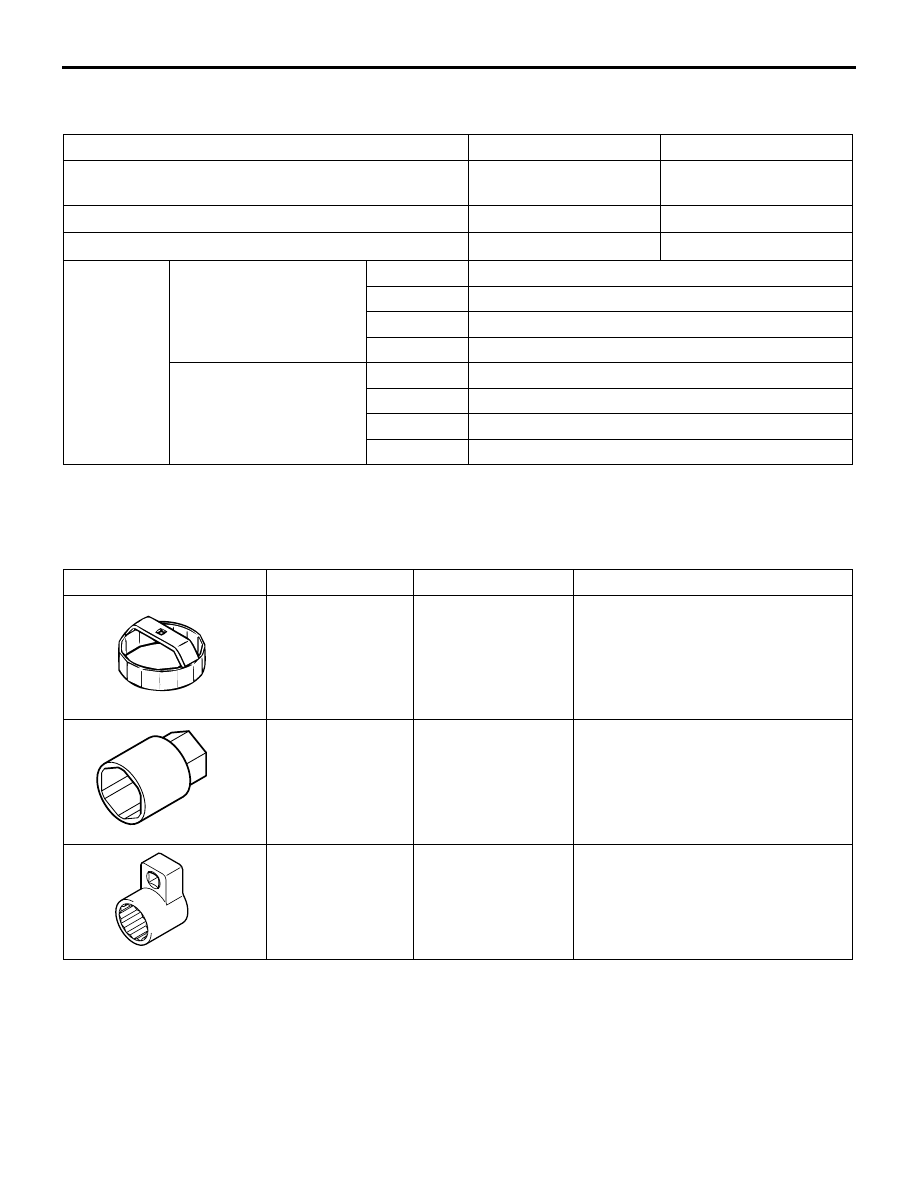

Item

Vehicles without DPF

Vehicles with DPF

Engine oil ACEA classification

A1/B1, A3/B3, A3/B4 or

A5/B5

C1, C2, C3 or C4

Engine oil API classification

CF-4

‚àí

Engine oil JASO classification

‚àí

DL-1

Engine oil

quantity L

2WD with 15 inch tyres

Oil pan

6.5

Oil filter

0.8

Oil cooler

0.1

Total

7.4

2WD with 16 inch tyres,

4WD

Oil pan

5.5

Oil filter

0.8

Oil cooler

0.1

Total

6.4

SPECIAL TOOLS

M1121000602433

Tool

Number

Name

Use

MH061590

MH061590

Oil filter wrench

Removal and installation of engine

oil filter

MD998012

Oil pressure switch

wrench

Removal and installation of engine

oil pressure switch <Except Euro5>

MB992118

MB992118

Oil pressure switch

wrench

Removal and installation of engine

oil pressure switch <Euro5>

ON-VEHICLE SERVICE

ENGINE LUBRICATION

12-4

ON-VEHICLE SERVICE

ENGINE OIL CHECK

M1121000901475

ACB00687

"X" mark

Maximum

Minimum

AB

CAUTION

When burning away and removing soot accumu-

lated in the DPF, fuel can mix with the engine oil

and an increase in the engine oil level may occur.

This does not indicate an abnormality. However,

if the engine oil level is at or over the "X" mark on

the engine oil level gauge, change the engine oil

<Vehicles with diesel particulate filter (DPF)>.

1. Pull out the engine oil level gauge slowly and

check that the engine oil level is in the illustrated

range.

2. Check that the engine oil is not excessively dirty,

that there is no engine coolant or fuel mixed in,

and that it has sufficient viscosity.

ENGINE OIL REPLACEMENT

M1121001003608

<Vehicles without diesel particulate filter

(DPF)>

1. Start the engine and allow it to warm up until the

temperature of the coolant reaches 80

°C to 90

°C.

2. Remove the engine oil filler cap.

WARNING

Use care as oil could be hot.

3. Remove the drain plug to drain oil.

AC502277

Engine oil

pan side

Engine oil pan

drain plug

AC

4. Install a new drain plug gasket so that it faces in

the direction shown in the illustration, and then

tighten the drain plug to the specified torque.

Tightening torque: 39

± 5 N⋅m

NOTE: Install the drain plug gasket so it faces in

the direction shown in the illustration.

5. Refill with specified quantity of oil.

Specified Engine Oil

• ACEA classification: "For service A1/B1,

A3/B3, A3/B4 or A5/B5"

• API classification: "For service CF-4"

Total quantity (Includes volume inside oil fil-

ter and oil cooler):

<2WD with 15 inch tyres> 7.4L

<2WD with 16 inch tyres, 4WD> 6.4L

NOTE:

AC903479

Select engine oil of the proper SAE viscosity

number according to the atmospheric tempera-

ture.

6. Install the engine oil filler cap.

7. Check oil level.

<Vehicles with diesel particulate filter

(DPF)>

1. Start the engine and allow it to warm up until the

temperature of the coolant reaches 80

°C to 90

°C.

2. Remove the engine oil filler cap.

WARNING

Use care as oil could be hot.

3. Remove the drain plug to drain oil.