Mitsubishi L200. Manual - part 47

CRANKSHAFT AND CYLINDER BLOCK

ENGINE OVERHAUL

11B-62

CRANKSHAFT AND CYLINDER BLOCK

REMOVAL AND INSTALLATION

M1113008704208

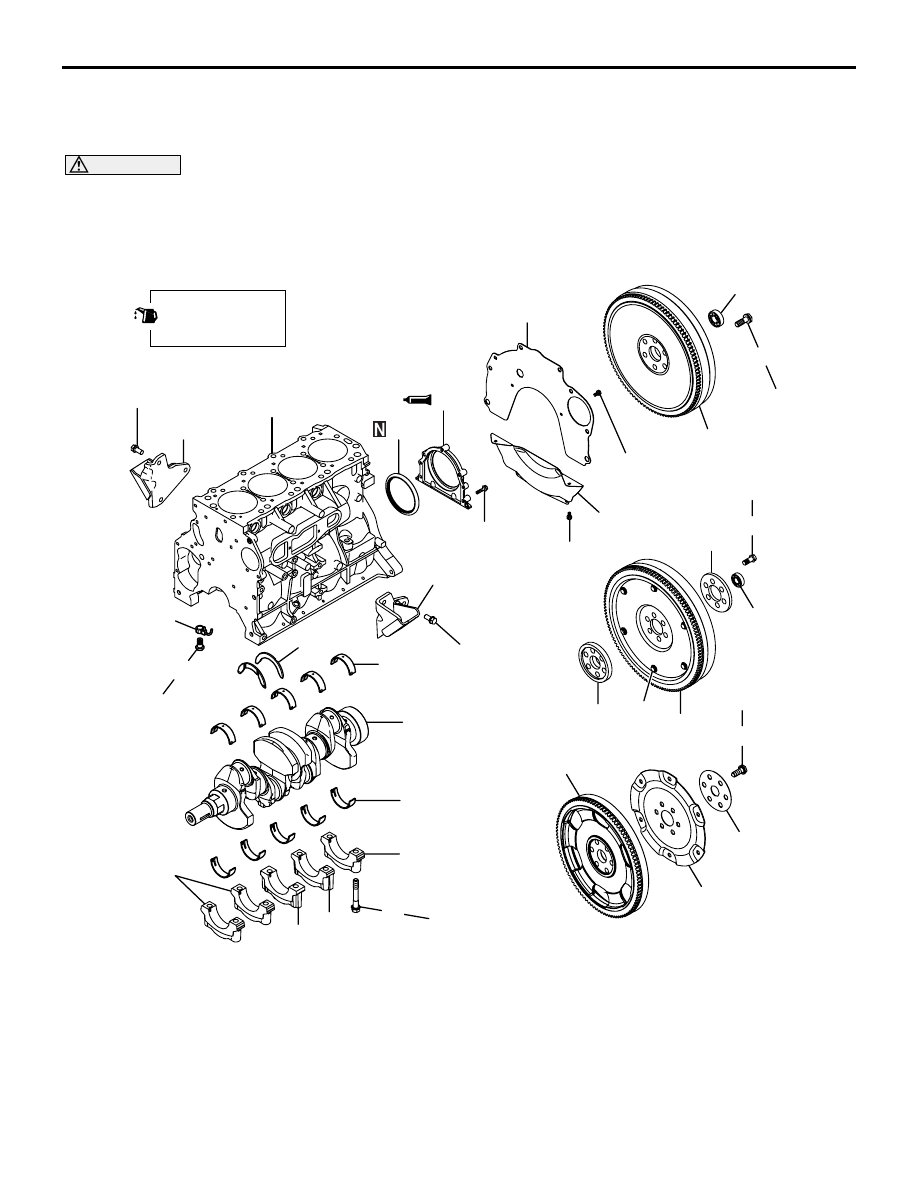

CAUTION

On the flexible flywheel equipped engines, do not remove any of the bolts "A" of the flywheel shown

in the illustration. The balance of the flexible flywheel is adjusted in an assembled condition. Remov-

ing the bolt, therefore, can cause the flexible flywheel to be out of balance giving and resulting in

damage.

AKB00336AB

Apply engine oil to

all moving parts

before installation.

1

3

2

4

7

8

13

14

16

28

27

133 ± 4 N·m

11 ± 1 N·m

9.0 ± 1.0 N·m

133 ± 4 N·m

9.0 ± 1.0 N·m

54 ± 5 N·m

54 ± 5 N·m

40 ± 2 N·m +35˚ to 39˚

32 ± 2 N·m

6

15

29

18

19

20

21

22

23

24

25

26

18

9

135 ± 5 N·m

12

10

A

11

5

17

Removal steps

1.

Flywheel bolt (M/T

−2WD)

2.

Ball bearing (M/T

−2WD)

3.

Flywheel (M/T

−2WD)

4.

Flywheel bolt (M/T

−4WD)

5.

Ball bearing (M/T

−4WD)

6.

Adapter (M/T

−4WD)

7.

Flexible flywheel (M/T

−4WD)

8.

Crankshaft adapter (M/T

−4WD)

9.

Drive plate bolt (A/T)

10. Adapter plate (A/T)

11. Drive plate (A/T)

12. Inertiar ring(A/T)

13. Rear plate

14. Bell housing cover

>>

E

<< 15. Oil seal case

>>

D

<< 16. Oil seal

>>

C

<< 17. Bearing cap bolt

>>

C

<< 18. Bearing cap

Removal steps (Continued)