Mitsubishi L200. Manual - part 45

OIL PAN AND OIL PUMP

ENGINE OVERHAUL

11B-54

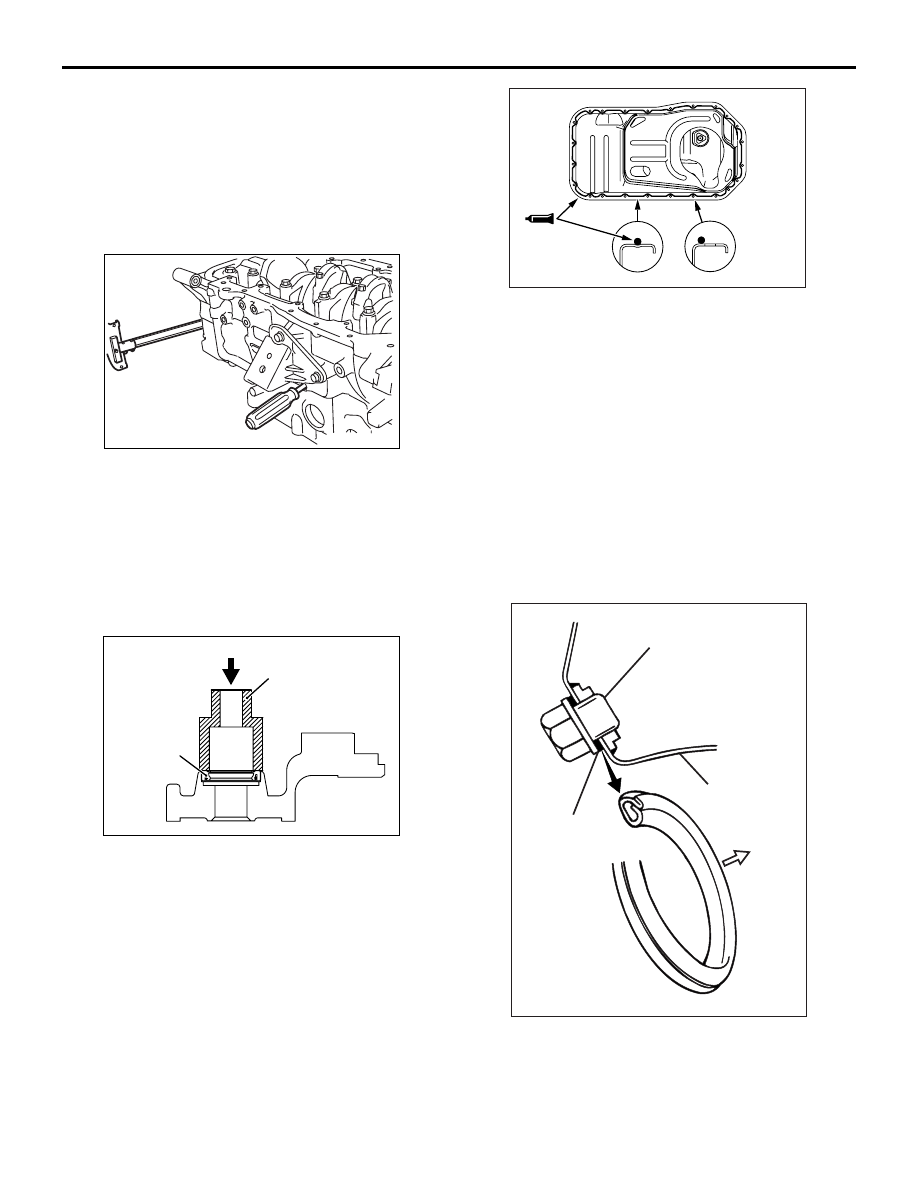

1. Attach the special tool Crankshaft front oil seal

guide (MD998383) to the crankshaft and apply

engine oil to the outer surface of the tool.

2. Using the special tool Crankshaft front oil seal

installer (MD998382), install the front oil seal into

the front lower case.

>>F<< FLANGE BOLT INSTALLATION

AK404132

1. Insert a Phillips screwdriver into the plug hole to

block the balancer shaft.

2. Install the flange bolt and tighten to the

specification.

3. Remove the screwdriver and install the plug.

>>G<< FRONT UPPER CASE OIL SEAL

INSTALLATION

AK500590AB

Socket wrench

Oil seal

Apply engine oil to the oil seal outer surface and

drive in with a socket wrench.

>>H<< OIL PAN / OIL PAN GASKET

INSTALLATION

Use either an oil pan gasket or a sealant for installing

the oil pan. Install the oil pan in accordance with the

following procedure respectively.

<SEALANT>

AK503041

Bolt

hole

portion

Groove

portion

AB

1. Clean both mating surfaces of oil pan and cylinder

block.

2. Apply a 4 mm wide bead of sealant to the entire

circumference of the oil pan flange.

Specified sealant:

Three bond 1217G or equivalent

3. The oil pan should be installed in 15 minutes after

the application of sealant.

<GASKET>

Clean both mating surfaces of oil pan and cylinder

block.

>>I<< OIL DRAIN PLUG GASKET INSTALLATION

AK300601AB

Drain plug

Oil pan

Gasket

Oil pan

side

Replace the gasket with a new one and install it in

the direction shown in the illustration.