Mitsubishi L200. Manual - part 37

TIMING BELT

ENGINE OVERHAUL

11B-22

REMOVAL SERVICE POINTS

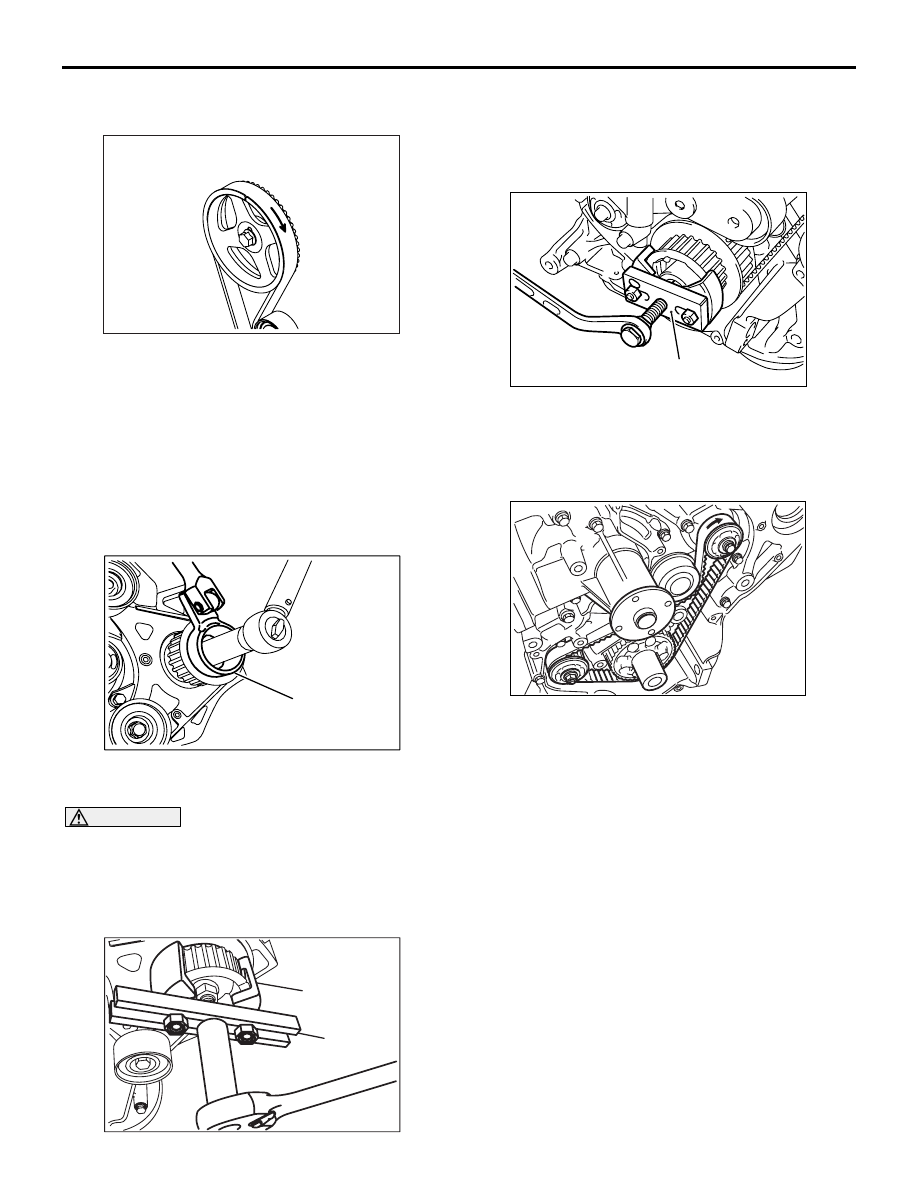

<<A>> TIMING BELT REMOVAL

AK500721

1. Using chalk, etc., mark an arrow on the back of

the timing belt to indicate the direction of rotation.

This is to ensure correct installation of the belt in

case it is reused.

<<B>> AUTO TENSIONER REMOVAL

Keep the auto-tensioner longitudinal. If it were kept

lateral, it would possibly cause aeration.

<<C>> PUMP SPROCKET REMOVAL

AK502995

MB992048

AC

1. Use the special tool Injection pump sprocket

holder (MB992048), hold the pump sprocket.

CAUTION

Never strike the shaft or sprocket to remove the

sprocket. This may cause malfunction in the

injection pump. Be sure to use a puller to remove

the sprocket.

2. Remove the pump sprocket nut.

AK503162AB

MB992098

MB992099

3. Use the special tool remove the pump sprocket.

• Injection pump sprocket puller (MB992098)

• Crank pulley puller (MB992099)

<<D>> CRANKSHAFT SPROCKET REMOVAL

AK404172 AB

MD998778

Use the special tool Crankshaft sprocket puller

(MD998778), if the sprocket is stuck and hard to

remove.

<<E>> TIMING BELT "B" REMOVAL

AK404168

Using chalk, etc., mark an arrow on the back of the

timing belt to indicate the direction of rotation. This is

to ensure correct installation of the belt in case it is

reused.

NOTE: Water or oil on the belt shortens its life drasti-

cally, so the removed timing belt, sprocket, and ten-

sioner must be free from oil and water. Do not

immerse parts in cleaning solvent.

NOTE: If there is oil or water on any part, check front

case oil seals, camshaft oil seal and water pump for

leaks.